Groove milling cutter

A groove milling cutter and cutter head technology, applied in milling cutters, milling machine equipment, manufacturing tools, etc., can solve the problems of poor contact between the coolant and the cutting part of the blade, poor cooling effect of the blade, and affecting the service life of the milling cutter blade. , to achieve the effect of good cooling effect, fast speed and reducing chip sticking to the knife

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

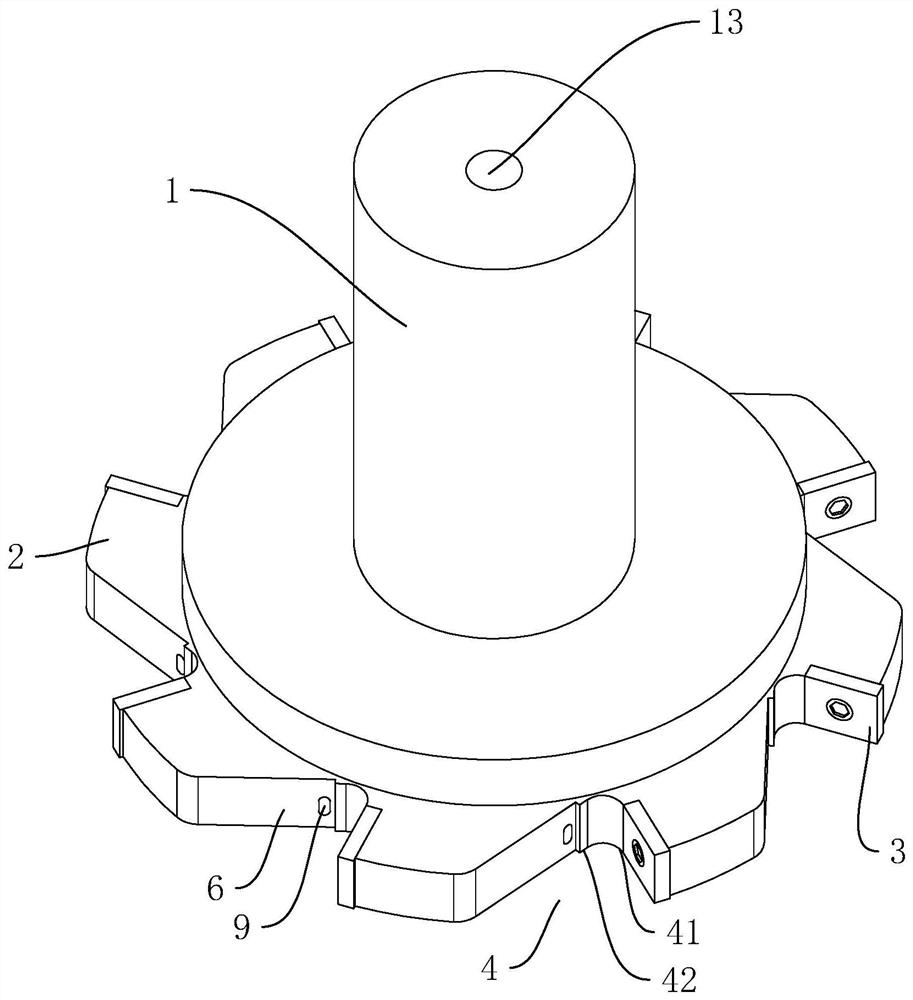

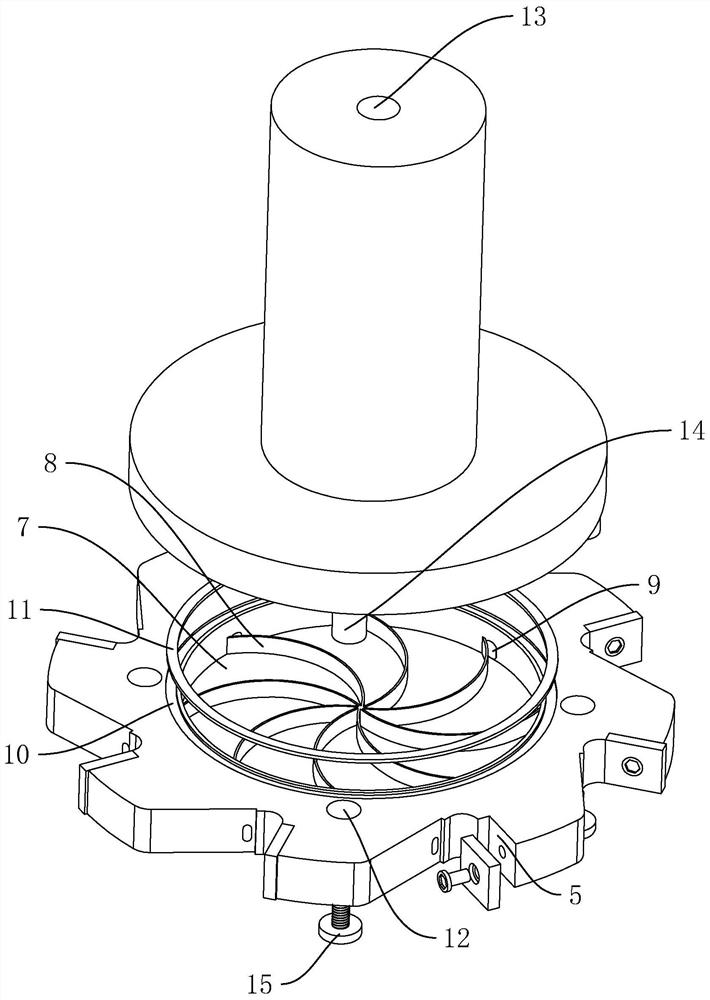

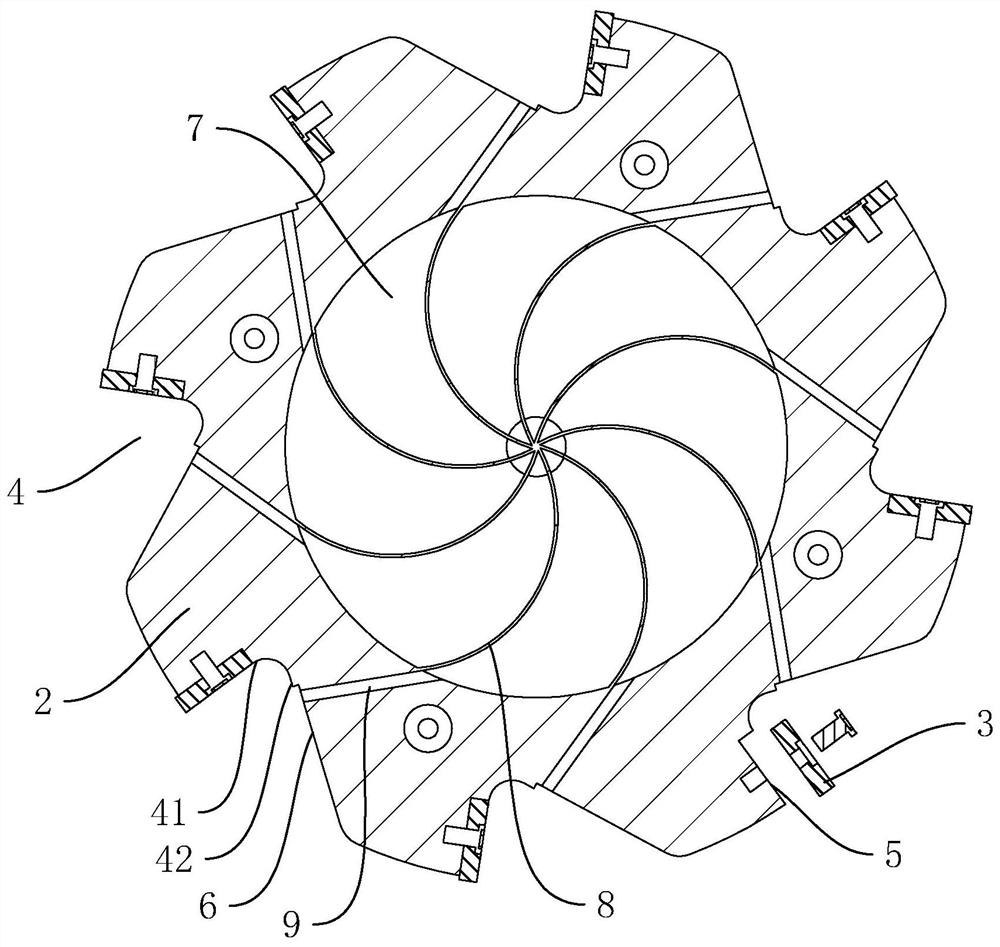

[0036] A slot milling cutter such as figure 1 As shown, it includes a tool handle 1 , a cutter head 2 coaxially fixed at one axial end of the handle 1 , and a blade 3 arranged on the cutter head 2 . The outer wall of the cutter head 2 is provided with at least two knife slots 4 . In this embodiment, there are eight knife slots 4 , and the eight knife slots 4 are evenly distributed along the axis of the cutter head 2 in the circumferential direction.

[0037] Such as figure 1 , figure 2 As shown, each knife slot 4 includes a mounting surface 41 and a material guiding surface 42. In this embodiment, the angle between the mounting surface 41 and the material guiding surface 42 is 70°. The mounting surface 41 of each knife slot 4 is arranged along the radial direction of the cutterhead 2, and the mounting surface 41 is provided with a mounting groove 5, and the mounting groove 5 is arranged through the cutterhead 2 towards an end away from the axis of the cutterhead 2. The num...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com