Horizontal type double-flue industrial coal powder boiler

A technology of pulverized coal boilers and double furnaces, which is applied in the direction of steam boilers, water heaters, lighting and heating equipment, etc., and can solve the problem that the structure cannot be directly applied to small and medium-sized industrial pulverized coal boilers. Different scale requirements, etc., to achieve the effect of compact and simple structure, flexible and convenient use, and prolonging the flue gas flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

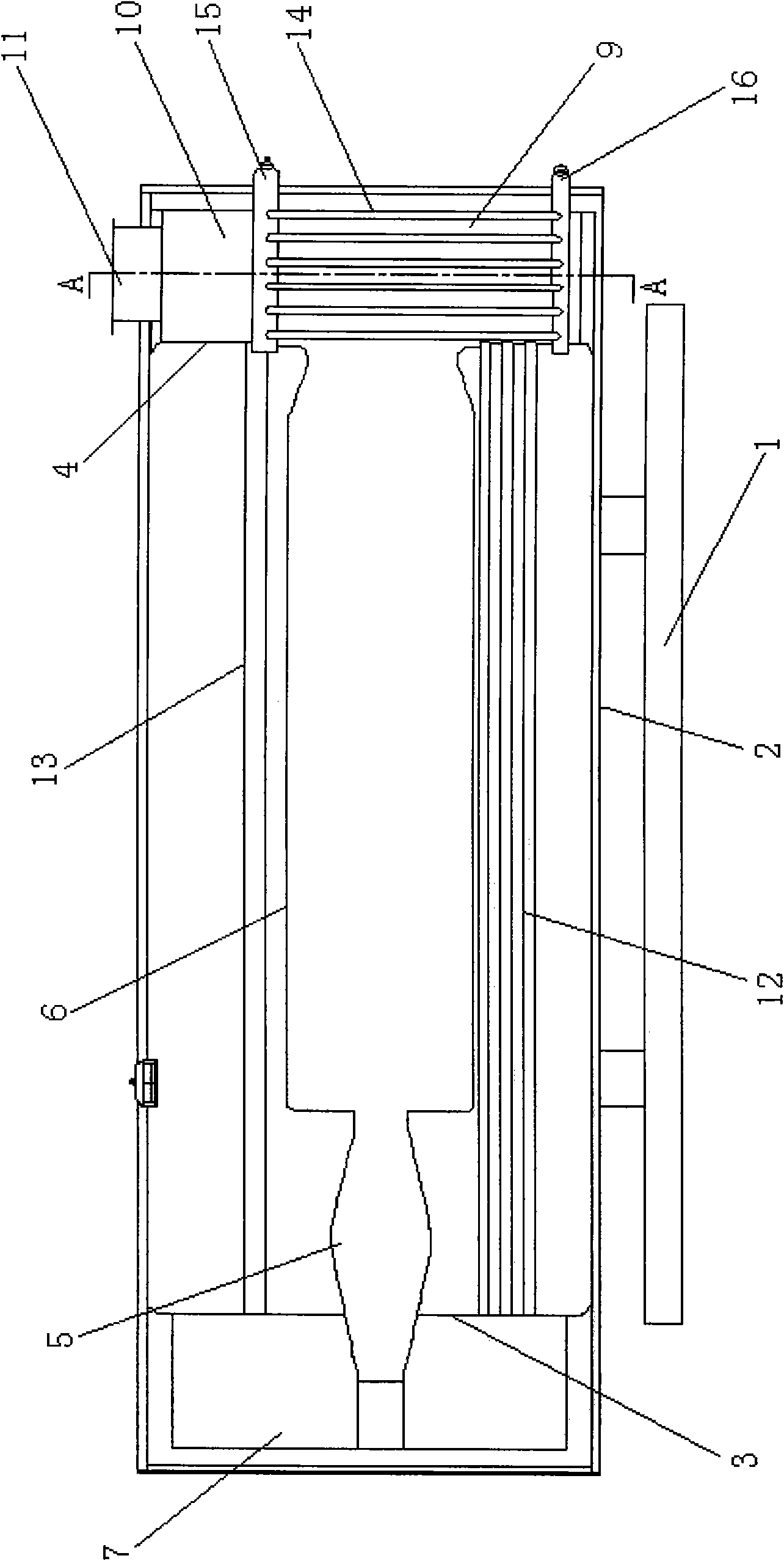

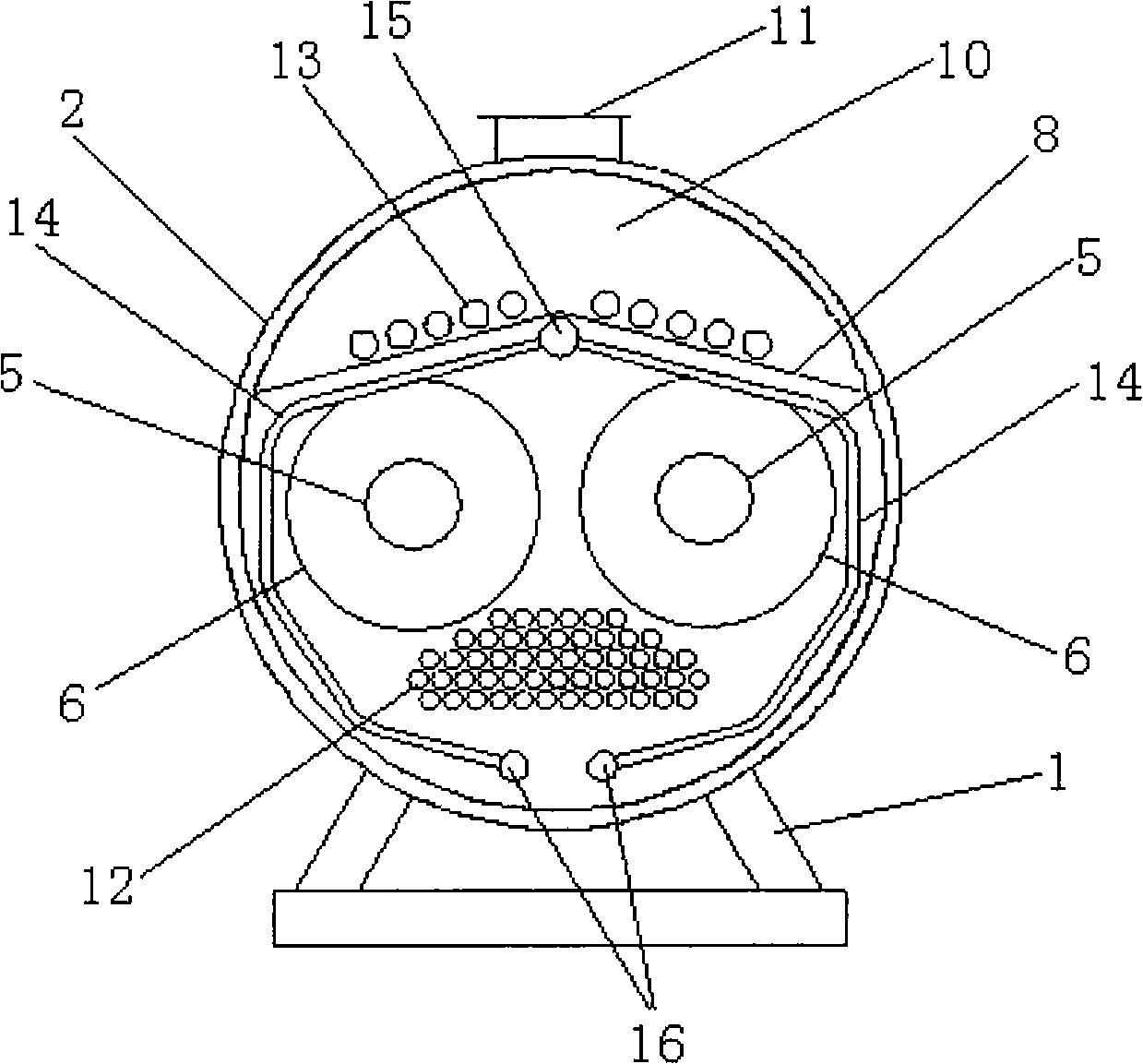

[0012] Such as figure 1 , figure 2 As shown, the present invention includes a cylindrical pot shell 2 placed horizontally on the tripod 1, and a front end plate 3 and a rear end plate 4 are respectively arranged at the front and rear of the pot shell 2. Two conical pre-chambers 5 are arranged axially side by side in the middle of the front end plate 3, and the pre-chambers 5 are composed of an expanding cone and a constricting cone. The inlet ends of the two pre-combustion chambers 5 are respectively connected to pulverized coal burners (not shown in the figure), and the outlet ends are respectively connected to one end of two horizontal furnaces 6 placed side by side in the pot shell 2, and the other ends of the two furnaces 6 One end communicates with the rear end plate 4 respectively. A front smoke box 7 is formed between the front end of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com