Fuel preparation and supply system and method for active pre-combustion chamber

A fuel preparation and supply system technology, applied in mechanical equipment, combustion engines, machines/engines, etc., can solve problems such as dirty scavenging, easy formation of carbon deposits, complex structure, etc., to increase convenience, prevent carbon deposits, The effect of high ignition energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

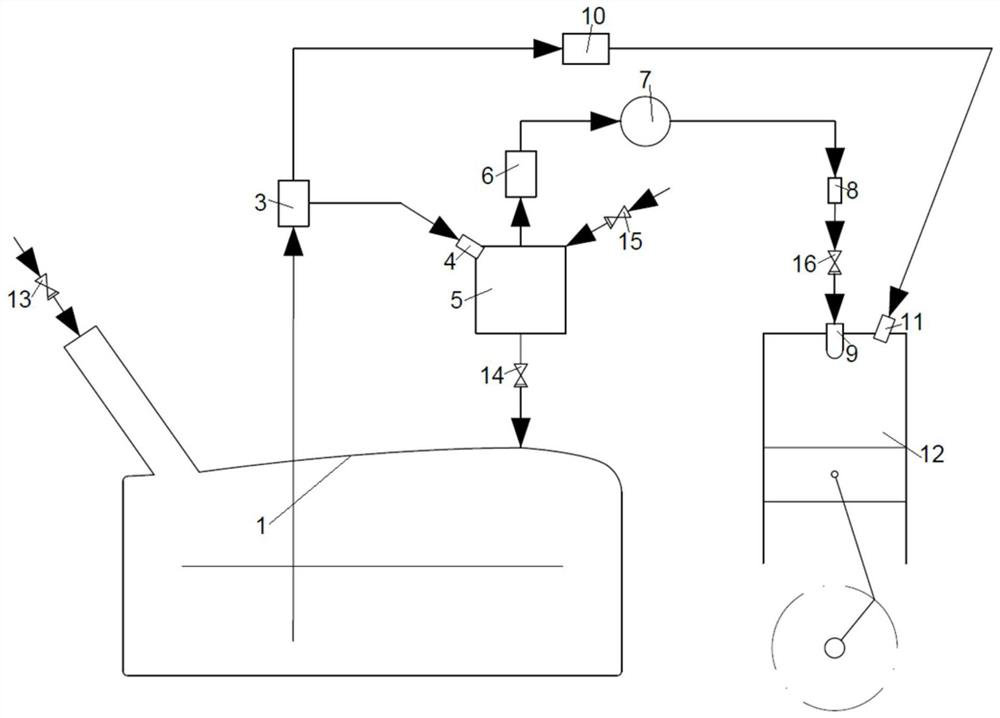

[0045] Such as figure 1 As shown, the present invention is a fuel preparation and supply system for an active pre-chamber, including a conventional fuel supply system and a fuel-air mixture preparation and supply system. A conventional fuel supply system includes a fuel tank 1, a fuel pipeline, a low-pressure fuel pump 3, a high-pressure fuel pump 10, a second fuel injector 11, a combustion chamber 12, and a fuel tank check valve 13. The fuel-air mixture preparation and supply system includes a fuel tank 1 , Fuel pipeline 2, low-pressure oil pump 3, first fuel injector 4, pre-mixing chamber 5, air pump 6, pressure regulating valve 7, gas nozzle 8, pre-chamber spark plug 9, combustion chamber 12.

[0046] The above design scheme can already complete the preparation and supply of fuel for the active pre-combustion chamber. Based on this scheme, the optimal scheme is given:

[0047] The premix chamber 5 is equipped with a premix chamber intake check valve 15 to ensure that there...

Embodiment 2

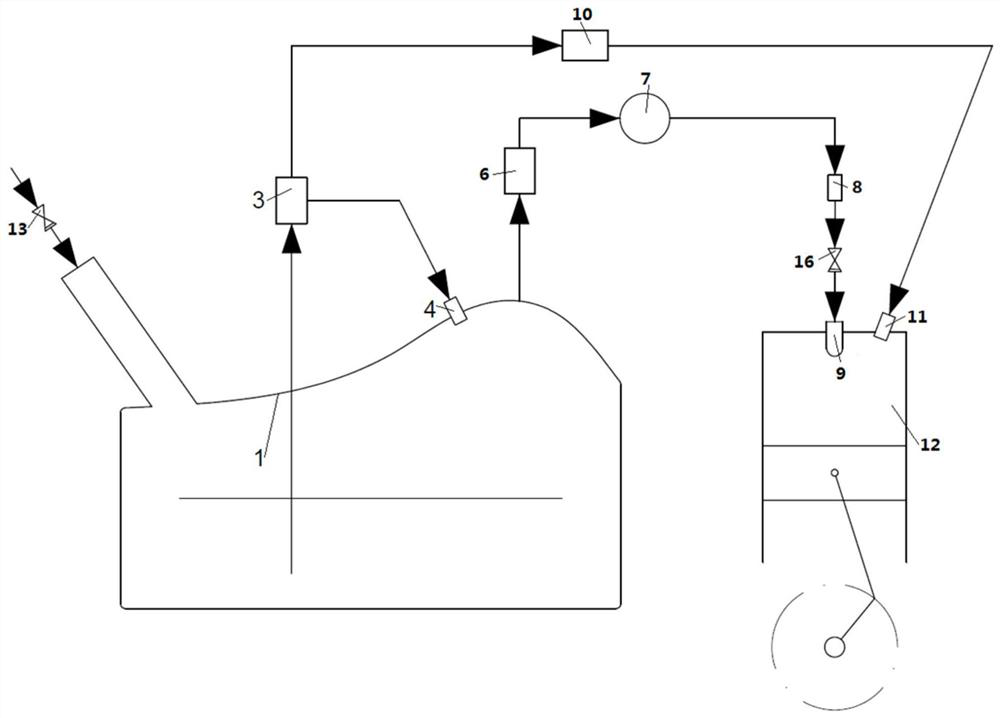

[0052] Such as figure 2 As shown, the present invention is a fuel preparation and supply system for an active pre-chamber, including a conventional fuel supply system and a fuel-air mixture preparation and supply system. A conventional fuel supply system includes a fuel tank 1, a fuel pipeline, a low-pressure fuel pump 3, a high-pressure fuel pump 10, a second fuel injector 11, a combustion chamber 12, and a fuel tank check valve 13. The fuel-air mixture preparation and supply system includes a fuel tank 1 , Fuel pipeline, low-pressure oil pump 3, first fuel injector 4, air pump 6, pressure regulating valve 7, gas nozzle 8, pre-chamber spark plug 9, combustion chamber 12, pre-chamber check valve 16.

[0053] The fuel tank 1 has a certain cavity to ensure that when the fuel tank is filled with oil, the fuel injector can spray oil mist into the cavity. The pre-chamber spark plug 9 is a spark plug with a pre-chamber structure. And a pre-chamber check valve 16 is installed on t...

Embodiment 3

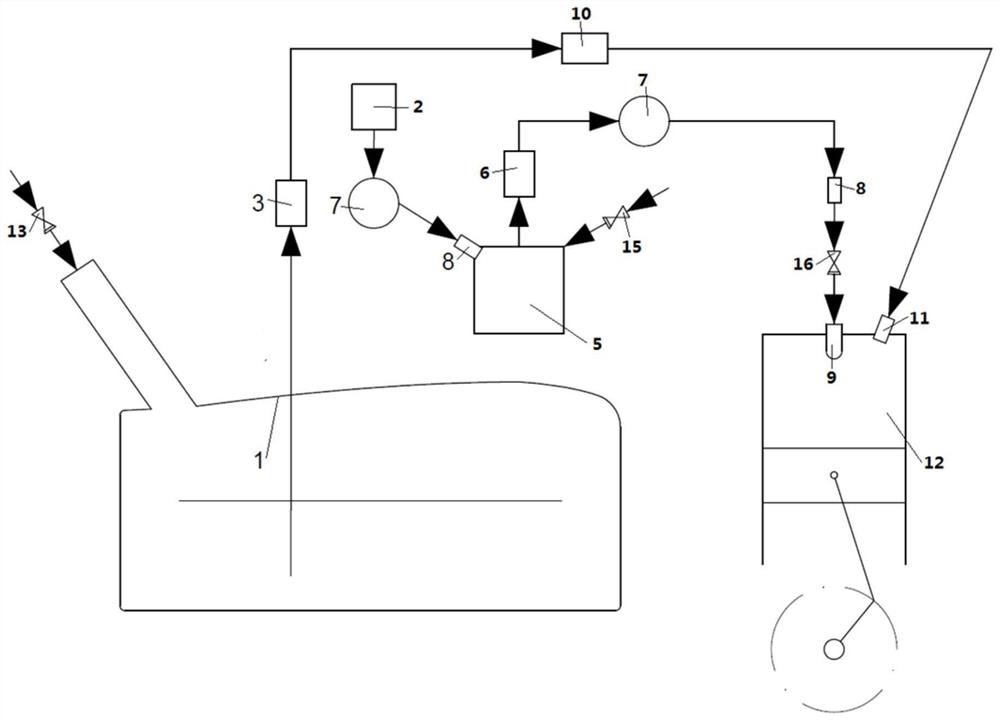

[0055] Such as image 3 As shown, the present invention is a fuel preparation and supply system for an active pre-combustion chamber, including a conventional fuel supply system and a second fuel gas preparation and supply system. A conventional fuel supply system includes a fuel tank 1, a fuel pipeline, a low-pressure oil pump 3, a high-pressure oil pump 10, a second fuel injector 11, a combustion chamber 12, and a fuel tank check valve 13. The second fuel gas fuel preparation and supply system includes a gas bottle 2 (specifically, high-pressure gas cylinder / liquefied gas cylinder can be used), pressure regulating valve 7, gas nozzle 8, pre-mixing chamber 5, air pump 6, another pressure regulating valve 7, another gas nozzle 8, pre-combustion chamber spark plug 9, Combustion chamber 12, premix chamber intake check valve 15, pre-combustion chamber check valve 16.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com