Slot jet flow gas film cooling structure for end wall of turbine

A technology of film cooling and air flow, applied in the direction of blade support components, stators, engine components, etc., can solve the problem of not improving the cooling efficiency of the turbine end wall, not significantly improving the jet tangential velocity, reducing the flow of cold air jets, etc. problems, to achieve the effect of avoiding the loss of cold air, improving the efficiency of film cooling, and improving the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

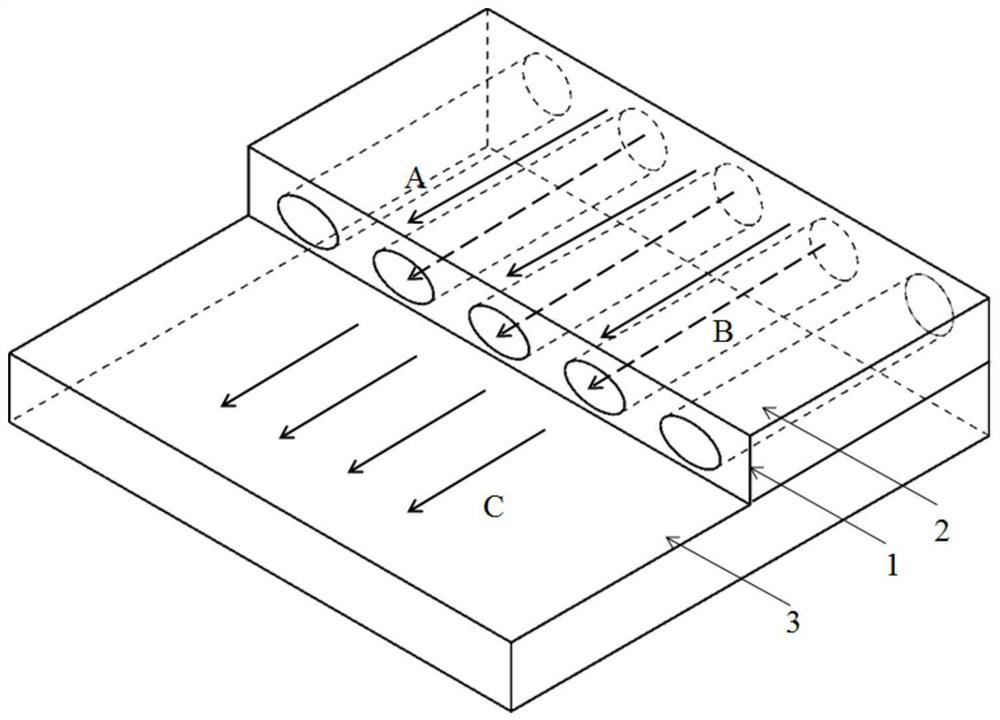

[0033] This embodiment is a cylindrical slot jet air film cooling structure on the end wall of the turbine vane. Arranged upstream of the turbine vane end wall 6 is a rearward stepped structure 5 , a jet air film hole 7 , and a slot air supply cavity 8 . It is characterized in that a slot jet air film hole 7 is arranged inside the backward step 5, wherein the outlet of the slot jet air film hole 7 is flush with the step surface of the backward step 5 and parallel to the plane 6 of the end wall of the turbine guide vane.

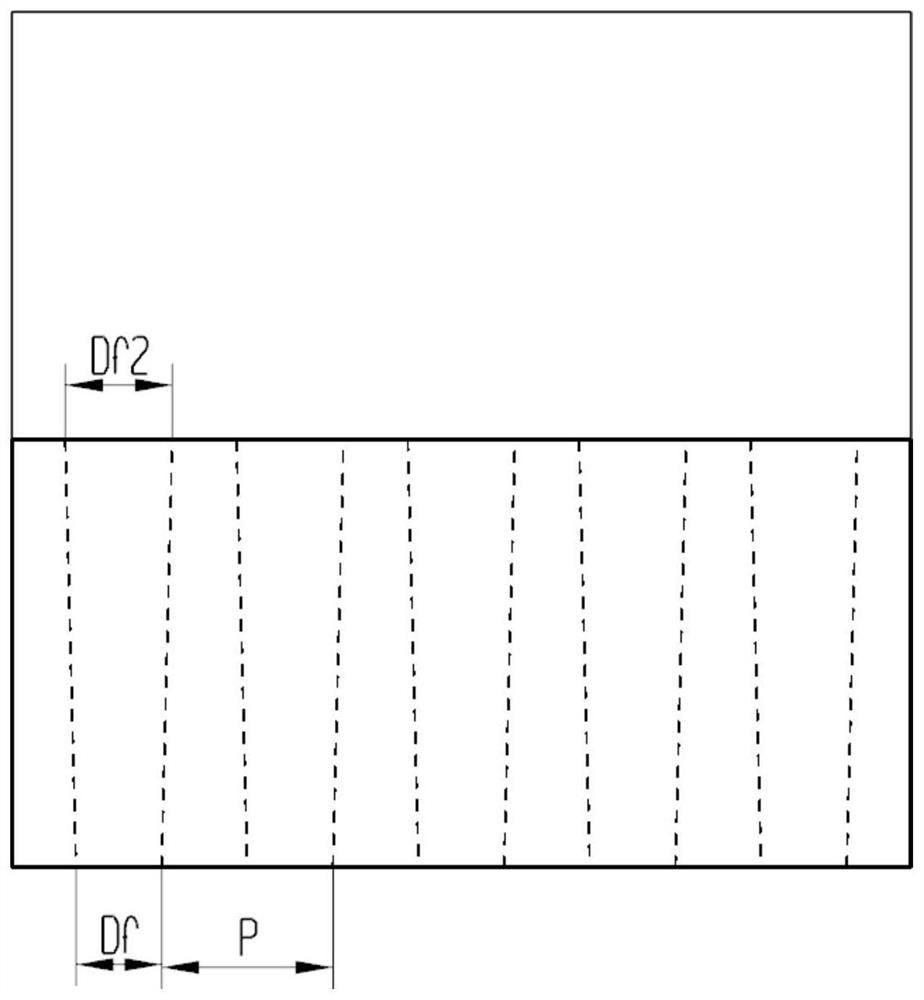

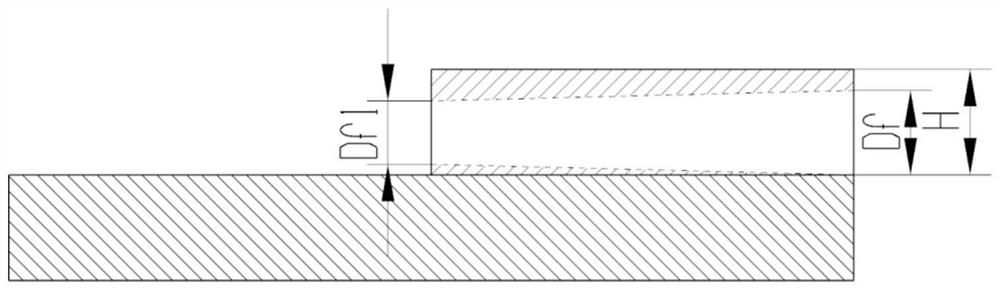

[0034] Jet film hole 2 inlet diameter D f 0.5mm, the short diameter of the air film hole 2 outlet D f1 is 0.5mm, and the long diameter of the outlet of air film hole 2 is D f2 0.5mm, the flow direction is the same as the mainstream.

[0035] The spanwise spacing P of the jet air film hole 2 is 2Df , whose value is 1mm.

[0036] The backward step height H is 2D f , whose value is 1mm.

[0037] The distance from the leading edge of the turbine guide vane ...

Embodiment 2

[0040] This embodiment is an expanding slot jet air film cooling structure on the end wall of the turbine guide vane. Arranged upstream of the turbine vane end wall 6 is a rearward stepped structure 5 , a jet air film hole 7 , and a slot air supply cavity 8 . It is characterized in that a slot jet air film hole 7 is arranged inside the backward step 5, wherein the outlet of the slot jet air film hole 7 is flush with the step surface of the backward step 5 and parallel to the plane 6 of the end wall of the turbine guide vane.

[0041] Jet film hole 2 inlet diameter D f 0.5mm, the short diameter of the air film hole 2 outlet D f1 is 0.5mm, and the long diameter of the outlet of air film hole 2 is D f2 0.7mm, the flow direction is the same as the mainstream.

[0042] The spanwise spacing P of jet air film holes 2 is 3D f , whose value is 1.5mm.

[0043] The backward step height H is 2D f , whose value is 1mm.

[0044] The distance from the leading edge of the turbine guide...

Embodiment 3

[0047] This embodiment is a tapered and diverging slot jet air film cooling structure on the end wall of the turbine vane. Arranged upstream of the turbine vane end wall 6 is a rearward stepped structure 5 , a jet air film hole 7 , and a slot air supply cavity 8 . It is characterized in that a slot jet air film hole 7 is arranged inside the backward step 5, wherein the outlet of the slot jet air film hole 7 is flush with the step surface of the backward step 5 and parallel to the plane 6 of the end wall of the turbine guide vane.

[0048] Jet film hole 2 inlet diameter D f 0.5mm, the short diameter of the air film hole 2 outlet D f1 is 0.35mm, and the long diameter of the outlet of air film hole 2 is D f2 0.7mm, the flow direction is the same as the mainstream.

[0049] The spanwise spacing P of jet air film holes 2 is 3D f , whose value is 1.5mm.

[0050] The backward step height H is 2D f , whose value is 1mm.

[0051] The distance from the leading edge of the turbine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com