Multi-cavity drum-type electrostatic spinning device and using method thereof

An electrospinning and receiving device technology, which is applied in the field of multi-cavity drum type electrospinning devices, can solve the problems of electric field interference, splashing around, and easy breakdown of device components, so as to improve production efficiency, product quality, and receiving direction Concentration and unification, the effect of eliminating the interference of the electric field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A

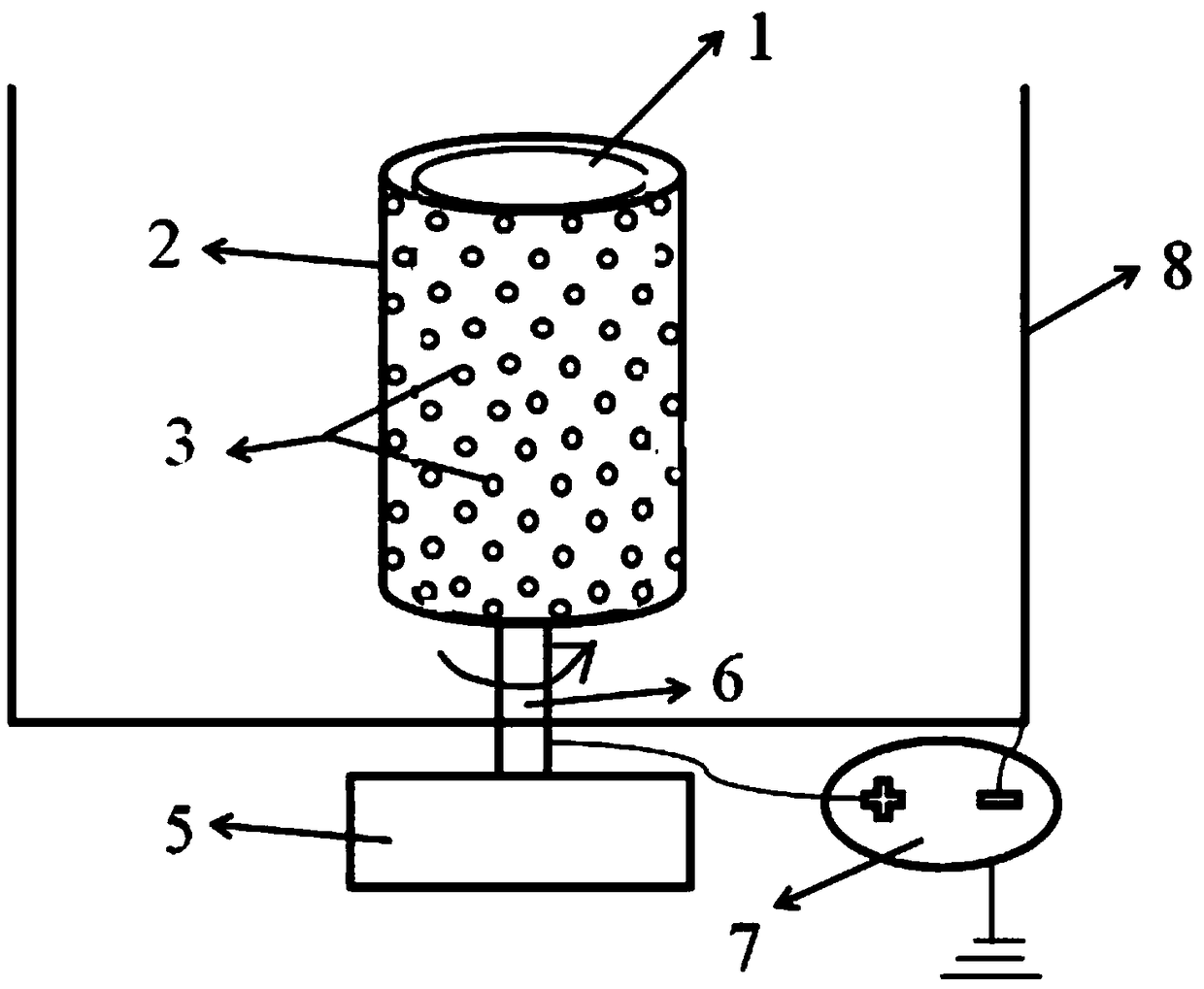

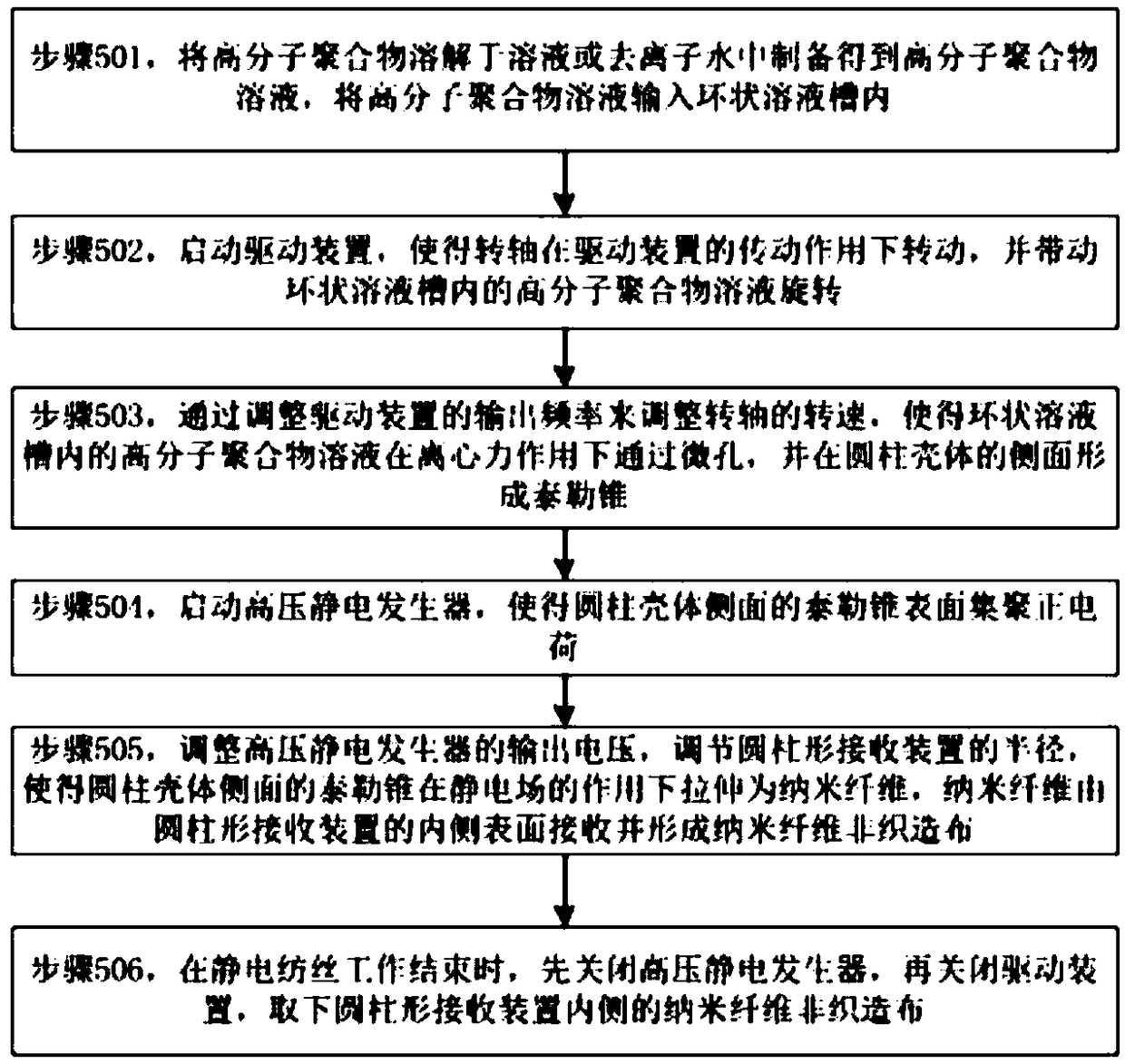

[0062] Dissolve 80 g of polyethylene oxide (PE0, molecular weight: 400,000) in 1920 mL of deionized water, stir in a normal temperature water bath to prepare a transparent polymer solution with a mass concentration of 4% without precipitation, and put it into a ring Electrospinning was carried out in the solution tank, the rotational speed of the rotating shaft was 4000r / min, the distance from the inner surface of the cylindrical receiving device to the cylindrical shell was 55cm, and the applied voltage was 45KV. According to the implementation steps of the method of using the above-mentioned multi-cavity rolling electrospinning device, a nanofiber nonwoven fabric is obtained, the fiber diameter is distributed between 300-700nm, and the average output is 11g / h / m.

Embodiment B

[0064] Dissolve 10 g of polyacrylonitrile (PAN, molecular weight 80,000) in 900 g of dimethylacetamide, stir in a 65-degree water bath to prepare a transparent polymer solution with a mass concentration of 10% without precipitation, and put it into The electrospinning was carried out in the annular solution tank, the rotational speed of the rotating shaft was 4500r / min, the distance from the inner surface of the cylindrical receiving device to the cylindrical shell was 45cm, and the applied voltage was 55KV. According to the implementation steps of the method of using the above-mentioned multi-cavity drum-type electrospinning device, a nanofiber nonwoven fabric is obtained, the fiber diameter is distributed between 300~900nm, and the average output is 13g / h / m.

[0065] It can be seen that the fiber fineness prepared by adopting the multi-cavity drum type electrospinning device provided by the present invention can reach nanometer level, and the multi-cavity drum type electrospi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com