Large-flow three-stage pilot type electromagnetic valve

A pilot-operated solenoid valve and large flow technology, applied in the direction of valve lift, valve details, valve device, etc., can solve problems such as failure to meet system index requirements, excessive pressure load, slow response speed, etc., and achieve the miniaturization of the overall structure And lightweight design, control structure size, increase the effect of inflation speed and exhaust speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Below in conjunction with accompanying drawing and specific embodiment content of the present invention is described in further detail:

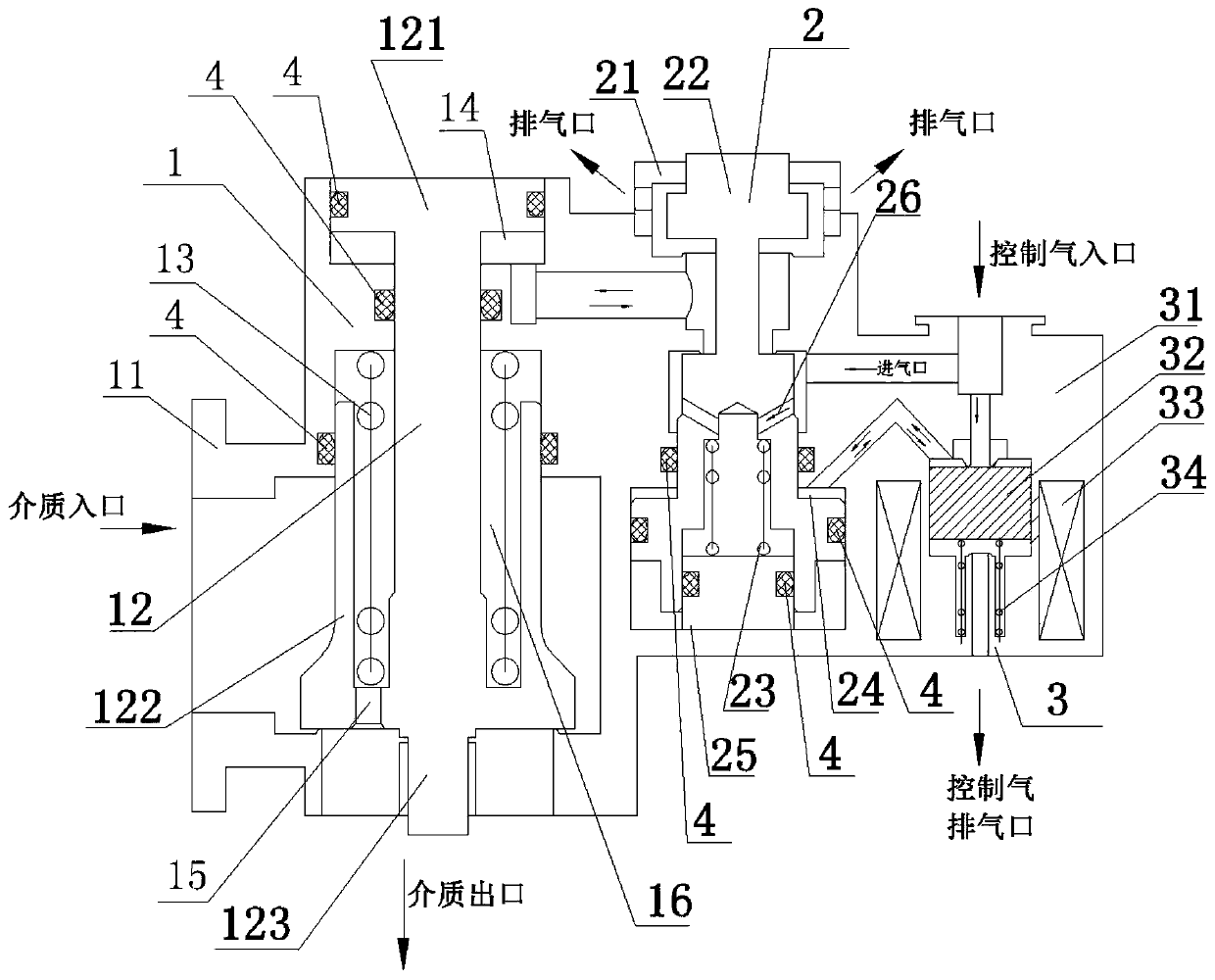

[0047] Such as figure 1 As shown, a large-flow three-stage pilot solenoid valve includes a first-stage solenoid pilot valve 3 , a second-stage air control pilot valve 2 and a three-stage control main valve 1 .

[0048] Wherein, the first-stage solenoid pilot valve 3 is a two-position three-way solenoid valve, including a solenoid pilot valve body 31 , a solenoid pilot valve core 32 , a solenoid pilot valve spring 34 and a coil 33 . The solenoid pilot valve body 31 is provided with a control gas inlet, a control gas outlet and a control gas exhaust port, wherein the solenoid pilot valve core 32 is located in the solenoid pilot valve body 31 and is compatible with the solenoid pilot valve body 31 The solenoid pilot valve spool 32 is provided with an air flow channel for connecting the control air outlet and the control air exhaust port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com