Axial-flow type safety block valve and overpressure cut-off control system thereof

A control system, axial flow technology, applied in the direction of safety valve, balance valve, valve device, etc., to achieve the effect of enhanced safety, low noise and large flow capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

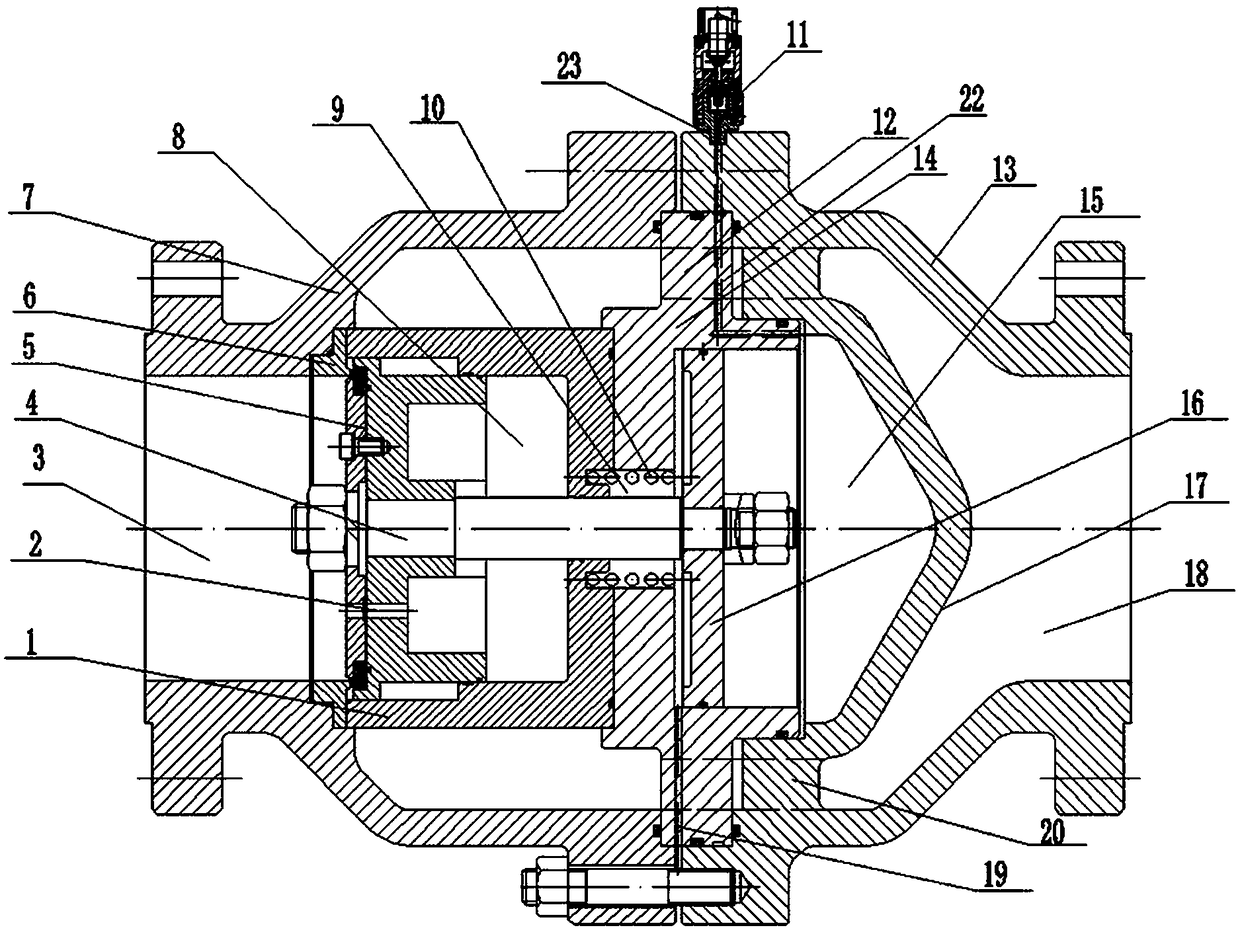

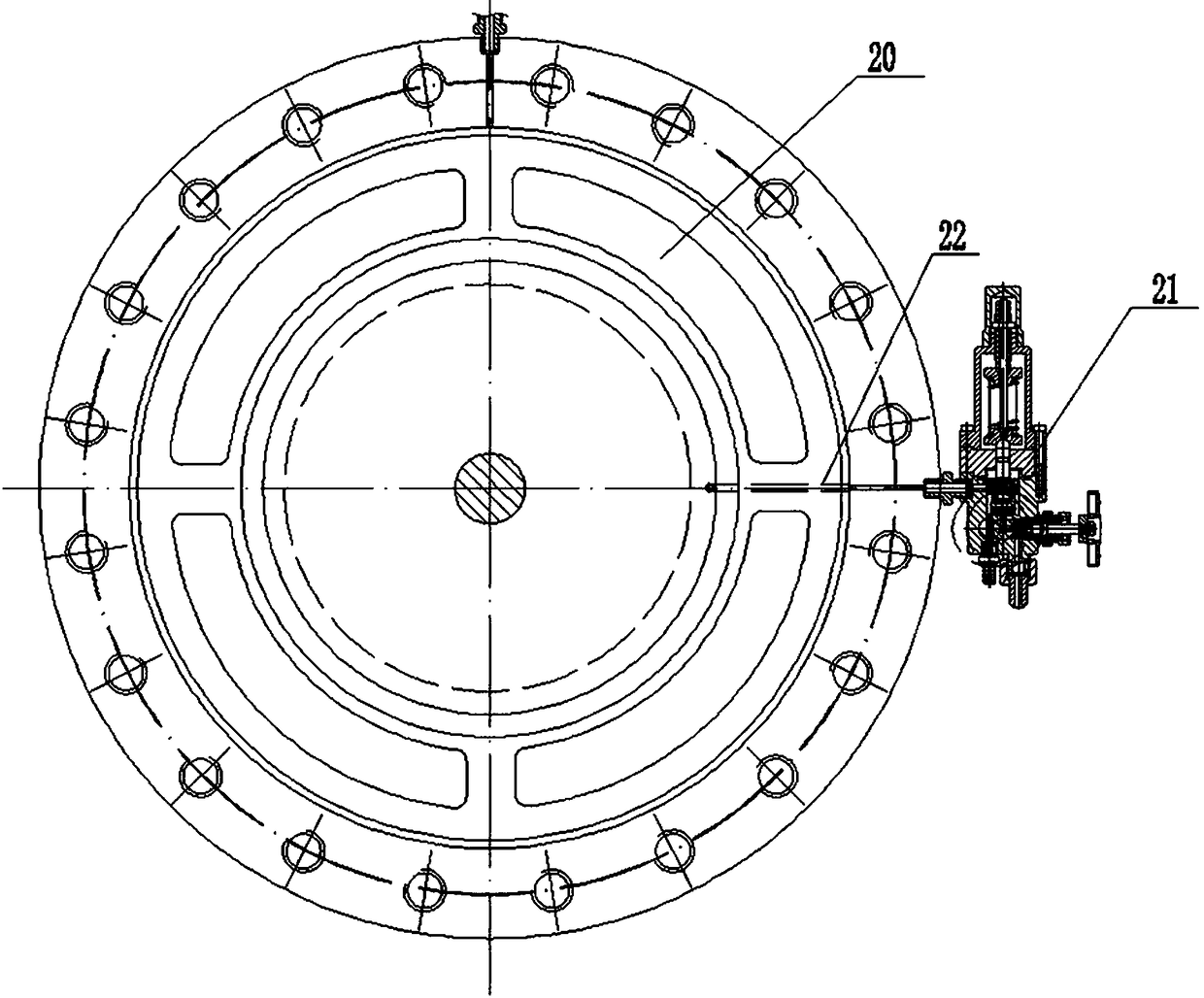

[0033] As a preferred embodiment of the application, refer to the attached figure 1 and 2 , this example discloses:

[0034] Axial flow safety cut-off valve, including left valve body 7, right valve body, valve seat 6, valve core 5, valve stem 4, valve core sleeve 1, piston sleeve 14 and piston 16, the right valve body includes Cover 17 and right valve body jacket 13; said spool 5, valve stem 4 and piston 16 constitute a power transmission mechanism; said left valve body 7, valve seat 6 and spool 5 constitute an inlet space 3; said spool 5 Slidingly connected in the valve core sleeve 1, the valve core 5 and the inner side of the valve core sleeve 1 form a left space 8, the right side of the valve core sleeve 1, the inner side of the piston sleeve 14 and the left side of the piston 16 form a damping space 9, and the damping The space 9 is provided with a return spring 10; the piston sleeve 14 is provided with a breathing hole 19, and the breathing hole 19 communicates the dam...

Embodiment 2

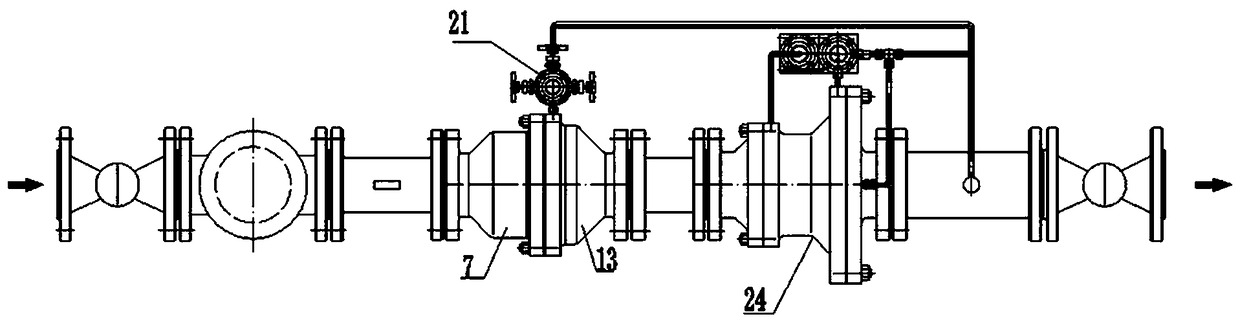

[0037] As another preferred embodiment of the present application, refer to the attached image 3 and 4 , this example discloses:

[0038] The overpressure cut-off control system of the axial-flow safety cut-off valve includes an axial-flow safety cut-off valve and several overpressure control valves 21; in this embodiment, according to the number of overpressure control valves 21, the overpressure cut-off control system can be Divided into a single overpressure cut-off method and a multi-stage overpressure cut-off method.

[0039] Such as image 3 As shown, the number of the overpressure control valve 21 is one, and the outlet of the overpressure control valve 21 communicates with the right space 15 of the axial flow safety shut-off valve, that is, the overpressure control valve is installed on the axial flow safety shutoff valve. At the interface of the instrument; the inlet of the overpressure control valve is connected with the downstream outlet pipeline. Typically the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com