Scratch-resistant low-speed cracking PE fuel gas pipe and preparation method thereof

A gas pipeline and protective layer technology, applied in the field of transportation pipelines, can solve problems such as easy scratches of gas pipelines, achieve good market prospects, long service life, and save existing resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

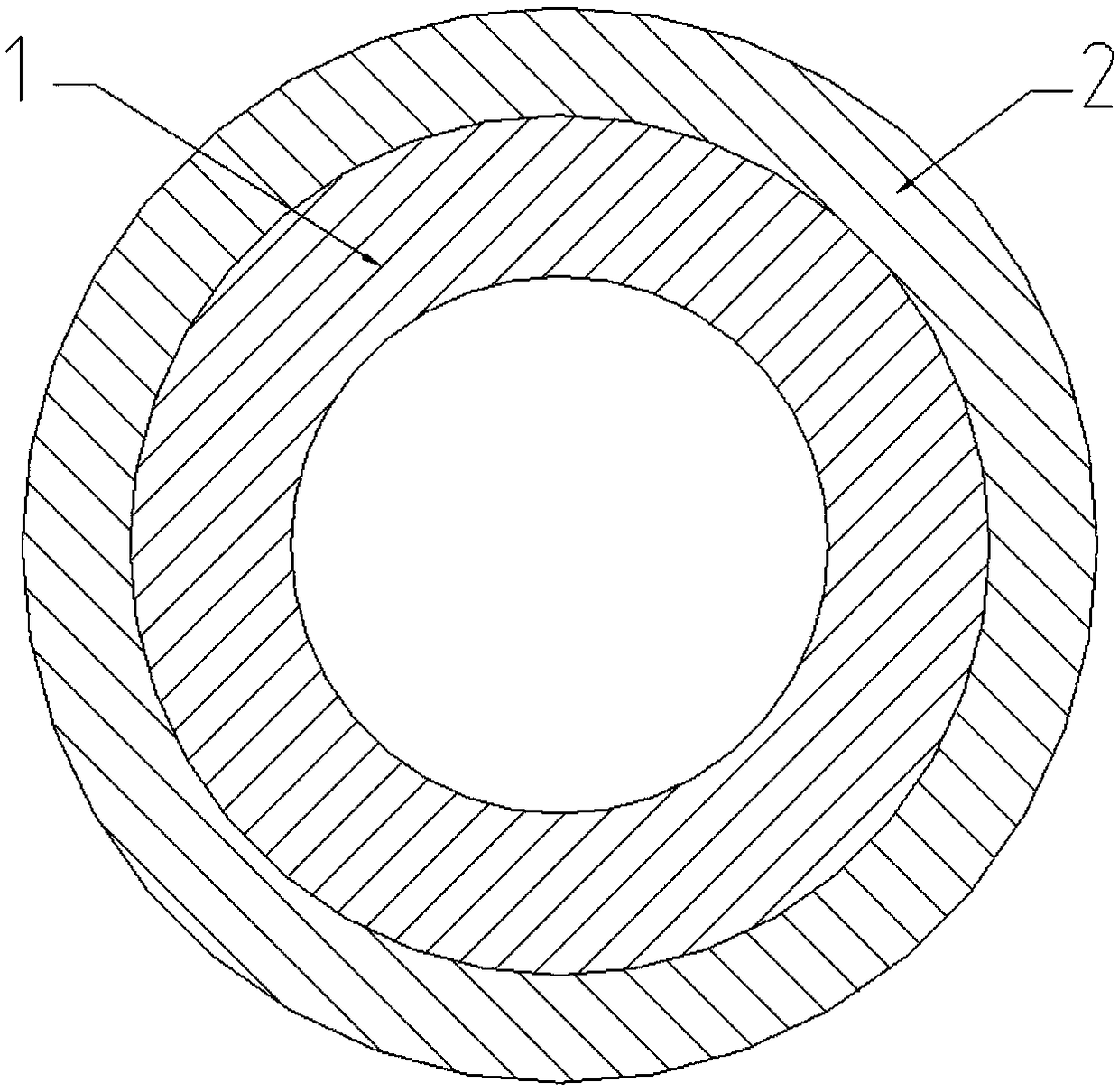

Image

Examples

Embodiment 1

[0038] A protective layer for gas pipelines, the composition and the specific weight of each composition are: 90 parts of heat-resistant polyethylene, 0.5 part of polysiloxane, 0.5 part of silane crosslinking agent, 0.1 part of graphene, 1 part of polyamide, disulfide 0.5 part of molybdenum, 1 part of glass fiber and carbon fiber composition, 0.5 part of maleic anhydride graft copolymer, and the thickness of the protective layer is 0.5 mm.

[0039] The mass ratio of the glass fiber and carbon fiber composition is: 1 part of glass fiber and 1 part of carbon fiber.

[0040] The preparation method of the above gas pipeline protective layer comprises the following steps:

[0041] S1. Mixing: Mix the above materials evenly at 50°C, and the mixing time is 3 minutes;

[0042] S2. Cooling: After the mixing is completed, cool to 28°C and set aside;

[0043] S3. Production of protective layer: add the material cooled in step S2 into the extruder, the temperature of the extruder is set...

Embodiment 2

[0045] A protective layer for a gas pipeline, the composition and the specific weight of each composition are: 100 parts of heat-resistant polyethylene, 5 parts of polysiloxane, 3 parts of silane crosslinking agent, 3 parts of graphene, 7 parts of polyamide, disulfide 5 parts of molybdenum, 6 parts of glass fiber and aromatic polyamide fiber composition, 5 parts of maleic anhydride graft copolymer, and the thickness of the protective layer is 3 mm.

[0046] The mass ratio of the composition of glass fiber and aromatic polyamide fiber is: 1 part of glass fiber and 1 part of aromatic polyamide fiber.

[0047] The preparation method of the above gas pipeline protective layer comprises the following steps:

[0048] S1. Mixing: Mix the above materials evenly at 65°C, and the mixing time is 6 minutes;

[0049] S2. Cooling: After the mixing is completed, cool to 29°C and set aside;

[0050] S3. Production of protective layer: Add the material cooled in step S2 into the extruder, se...

Embodiment 3

[0052] A protective layer for gas pipelines, the composition and the specific weight of each composition are: 110 parts of heat-resistant polyethylene, 10 parts of polysiloxane, 5 parts of silane crosslinking agent, 5 parts of graphene, 15 parts of polyamide, disulfide 10 parts of molybdenum, 10 parts of carbon fiber and aromatic polyamide fiber composition, 10 parts of maleic anhydride graft copolymer, and the thickness of the protective layer is 2 mm.

[0053] The mass ratio of the carbon fiber and aramid fiber composition is: 1 part of carbon fiber and 1 part of aramid fiber.

[0054] The preparation method of the above gas pipeline protective layer comprises the following steps:

[0055] S1. Mixing: Mix the above materials evenly at 80°C, and the mixing time is 10 minutes;

[0056] S2. Cooling: After the mixing is completed, cool to 30°C and set aside;

[0057]S3. Production of protective layer: Add the material cooled in step S2 into the extruder, set the temperature of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com