Lifting hydro-pneumatic suspension hydraulic system

A technology of hydraulic system and oil and gas suspension, applied in the field of hydraulic system, can solve the problem that the hydraulic system of the liftable oil and gas suspension cannot fully realize automatic control, reduce the reliability of the hydraulic system of the liftable oil and gas suspension, and reduce the hydraulic pressure of the liftable oil and gas suspension. System efficiency and other issues, to achieve excellent reliability and comprehensive performance, good anti-pollution, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

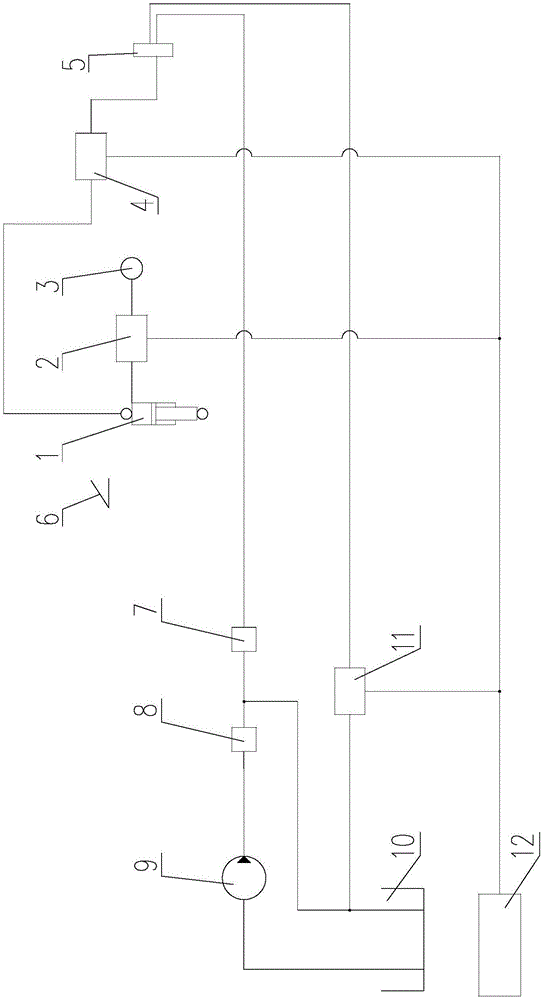

Image

Examples

Embodiment 1

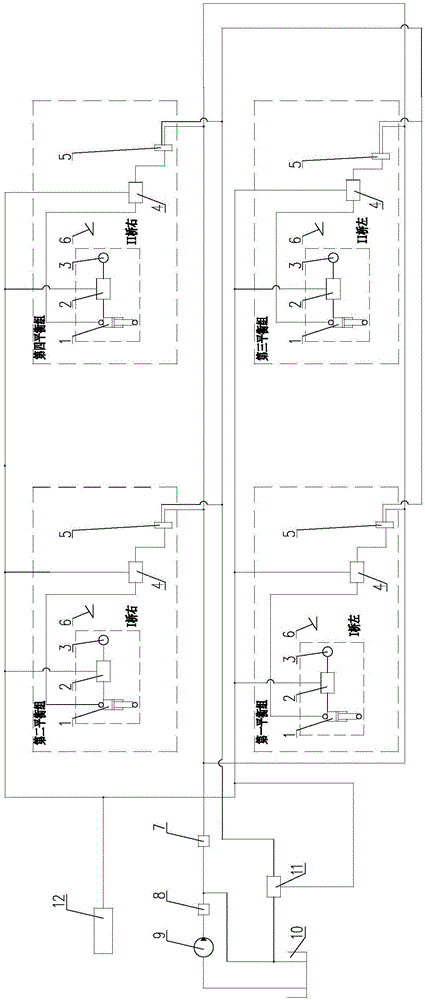

[0029] Such as figure 2 As shown, the present invention can lift the oil-pneumatic suspension hydraulic system, wherein the oil-pneumatic spring 1, the rigid cut-off valve 2, the accumulator 3, the angle sensor 6, the group oil return cut-off valve 4 and the electromagnetic reversing valve 5 form four balanced Group, the four balance groups are the first balance group, the second balance group, the third balance group and the fourth balance group, each balance group includes oil and gas spring 1, rigid stop valve 2, accumulator 3, angle sensor 6. Group oil return cut-off valve 4 and electromagnetic reversing valve 5, oil and gas spring 1, rigid stop valve 2, accumulator 3, angle sensor 6, group oil return stop valve 4 and electromagnetic reversing valve in each balance group 5 are all set to one.

[0030] This embodiment is applied to a two-axle super-heavy off-road vehicle, such as figure 2 As shown, the hydraulic system of the liftable oil-pneumatic suspension is divided...

Embodiment 2

[0034] Such as image 3 As shown, the present invention can lift the oil-pneumatic suspension hydraulic system, wherein the oil-pneumatic spring 1, the rigid cut-off valve 2, the accumulator 3, the angle sensor 6, the group oil return cut-off valve 4 and the electromagnetic reversing valve 5 form four balanced Group, the four balance groups are the first balance group, the second balance group, the third balance group and the fourth balance group, each balance group includes oil and gas spring 1, rigid stop valve 2, accumulator 3, angle sensor 6. Group oil return cut-off valve 4 and electromagnetic reversing valve 5, oil-gas spring 1, rigid stop valve 2, accumulator 3, angle sensor 6, group oil return cut-off valve in the first balance group and the second balance group The valve 4 and the electromagnetic reversing valve 5 are all set to one, and the grouping oil return cut-off valve 4 and the electromagnetic reversing valve 5 in the third balance group and the fourth balance ...

Embodiment 3

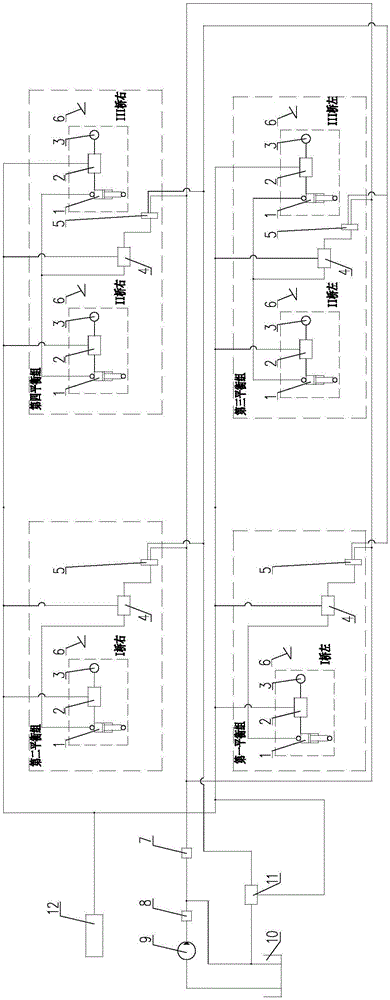

[0039] Such as Figure 4 As shown, the present invention can lift the oil-pneumatic suspension hydraulic system, wherein the oil-pneumatic spring 1, the rigid cut-off valve 2, the accumulator 3, the angle sensor 6, the group oil return cut-off valve 4 and the electromagnetic reversing valve 5 form four balanced Group, the four balance groups are the first balance group, the second balance group, the third balance group and the fourth balance group, each balance group includes oil and gas spring 1, rigid stop valve 2, accumulator 3, angle sensor 6. Group oil return cut-off valve 4 and electromagnetic reversing valve 5. Set one group oil return stop valve 4 and electromagnetic reversing valve 5 in each balance group. Oil-gas spring 1 and rigid cut-off valve in each balance group There are two valves 2, accumulators 3 and angle sensors 6.

[0040] This embodiment is applied to a four-axle super-heavy off-road vehicle, such as Figure 4 As shown, the hydraulic system of the lift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com