Pilot-operated type electromagnetic pneumatic valves and combined control valve

An electromagnetic pneumatic valve, pilot-operated technology, applied in the field of control valves, can solve the problems of not meeting the system design requirements, low working pressure, small flow capacity, etc., and achieve the effect of overcoming adverse effects, reducing driving load, and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention is described in detail below in conjunction with the embodiment that accompanying drawing provides:

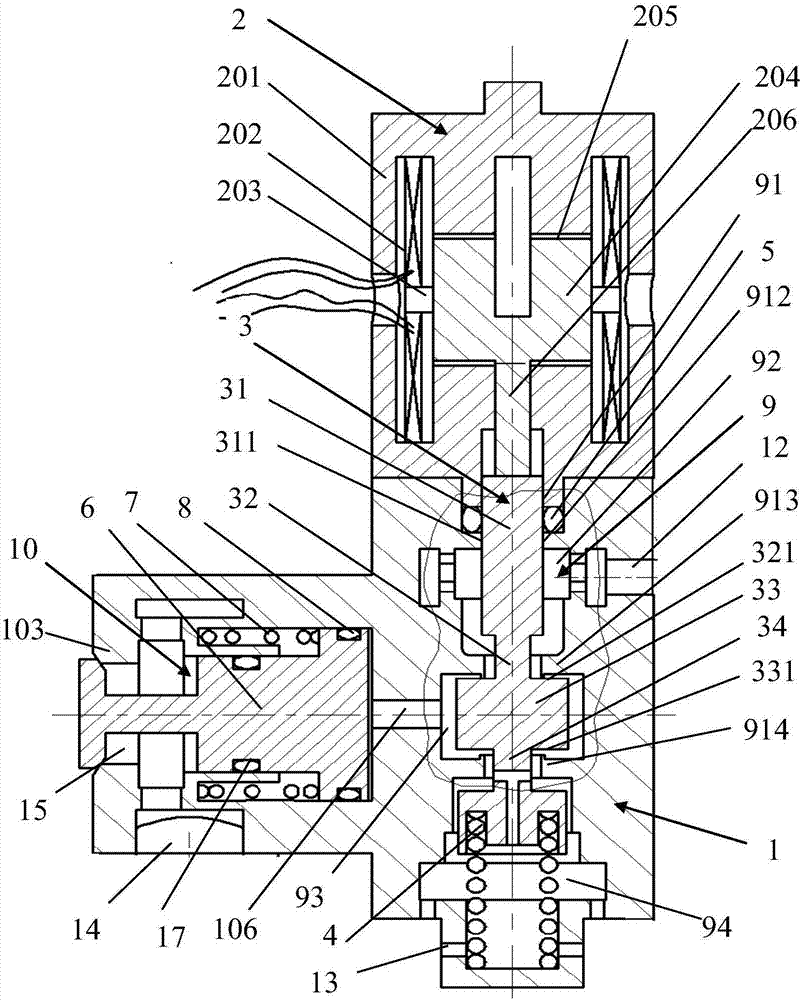

[0046] see figure 1 , a pilot-operated electromagnetic pneumatic valve, including a valve body 1, a pilot valve spool assembly, a main valve spool assembly and an electromagnetic coil drive device 2, the valve body 1 is provided with a pilot valve core installation cavity 9, a main valve core installation cavity 10. Air inlet 12, exhaust port 13, medium inlet 14 and medium outlet 15.

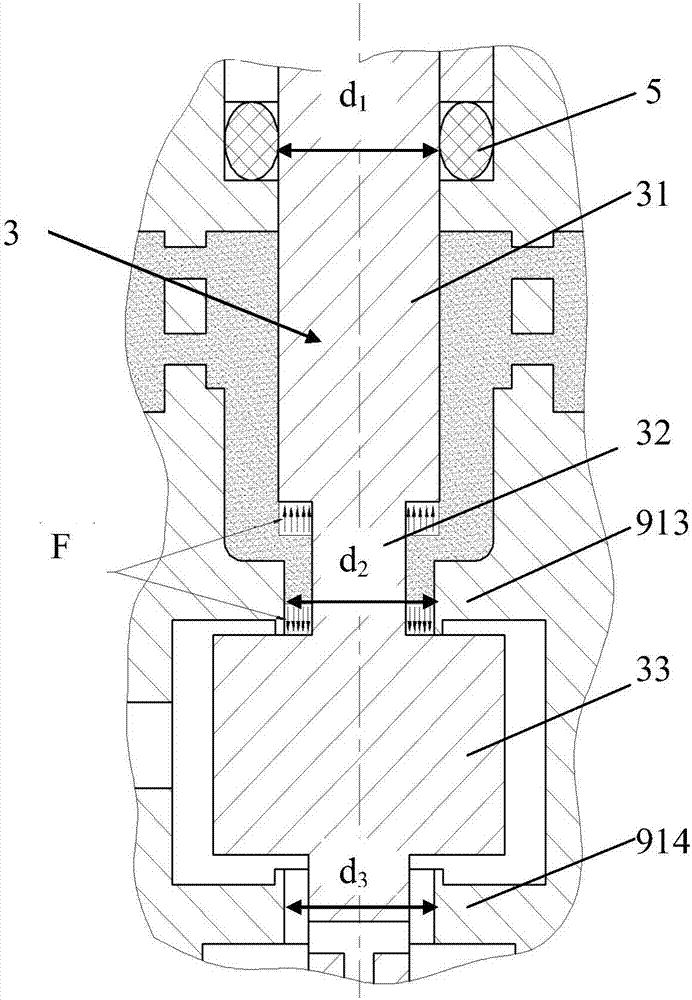

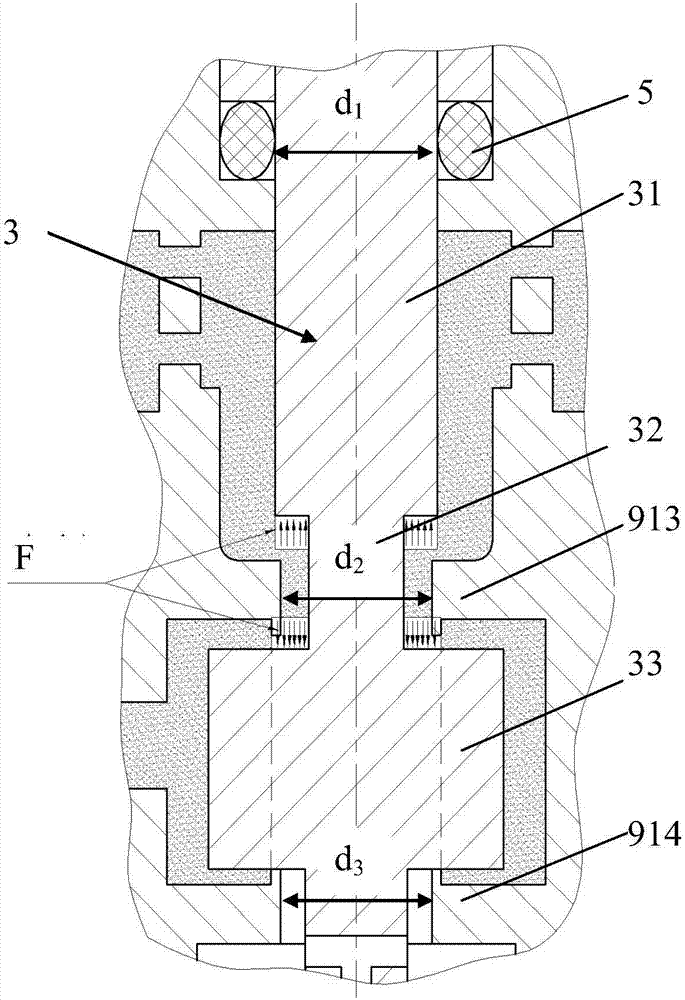

[0047] The pilot valve spool assembly is arranged in the pilot valve spool installation chamber 9 , the pilot valve spool assembly includes the pilot spool 3 , the first return spring 4 and the sealing element A5 ; the main valve spool assembly includes the main spool 6 .

[0048] The guide valve core installation cavity 9 is divided into the upper part 91 of the cavity, the upper part 92 of the cavity, the lower part 93 of the cavity and the lower part 94 of the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com