Flow sensor of heat energy meter

A technology of flow sensor and calorimeter, which is applied in the direction of calorimeter, measuring heat, measuring flow/mass flow, etc. It can solve the problems of large pressure loss of hot water, few common parts, easy wear of friction parts, etc., and achieve hot water pressure Small loss, wide flow range ratio, and good flow capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

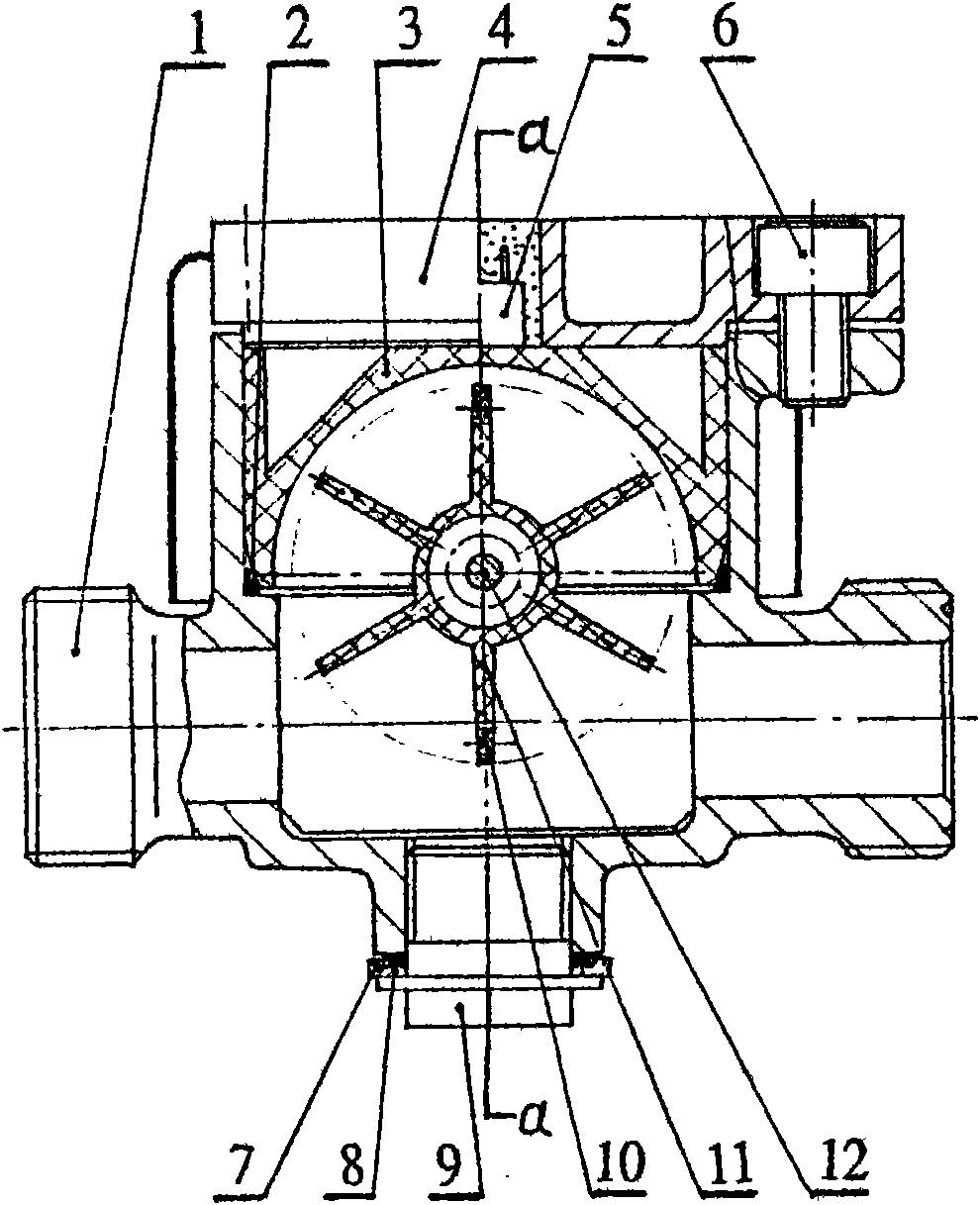

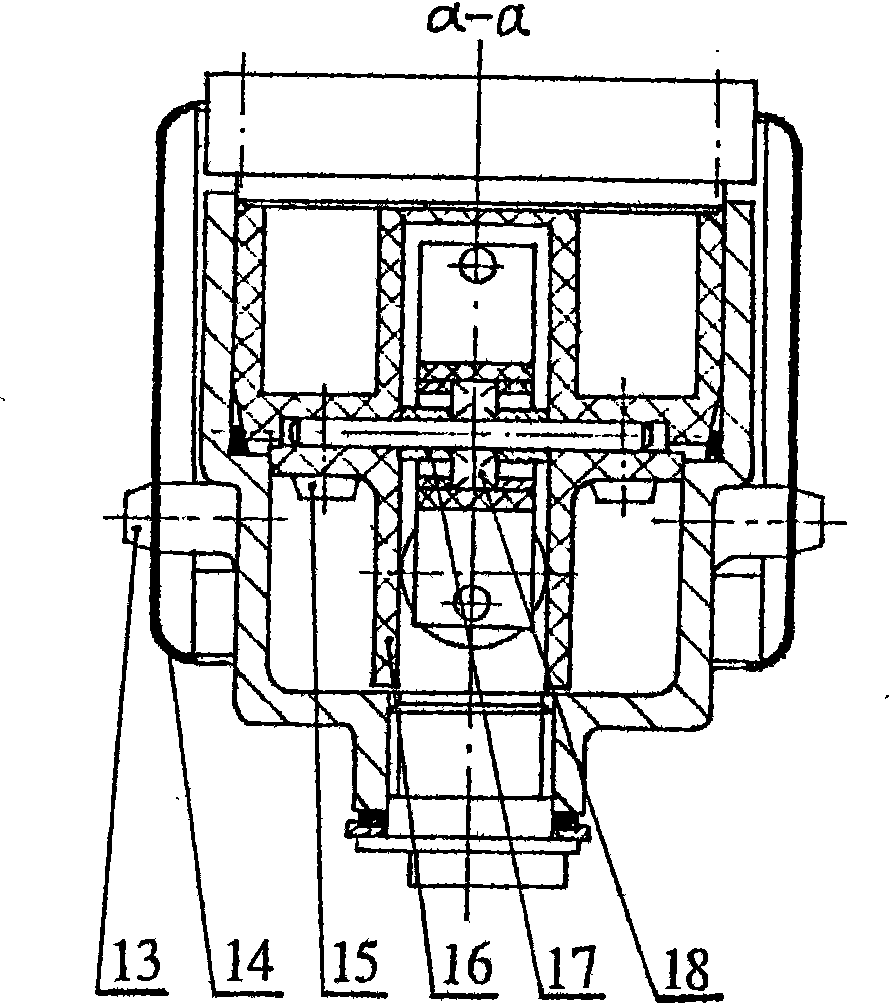

[0010] The thermal energy meter flow sensor of the present invention is realized in this way, which will be described in detail below in conjunction with the accompanying drawings. See figure 1 , figure 2 The thermal energy meter flow sensor is composed of: shell 1, sealing ring 2, impeller seat 3, gland 4, magnetoelectric converter 5, screw 6, washer 7, gasket 8, plug 9, magnetic element 10, impeller 11 , shaft 12, screw 13, magnetic shield 14, screw 15, rectifying plate 16, sleeve 17, rolling bearing 18, characterized in that: rolling bearing 18 is fixed in the hole of impeller 11 and the middle part of shaft 12 to form the impeller assembly; 2 sleeves 17 is installed on both sides of the shaft 12 and the rolling bearing 18 of the impeller assembly, the impeller assembly is placed in the groove of the impeller seat 3, and the shaft 12 of the impeller assembly is compressed with two rectifying plates 16 and screws 15 to form a movement. Put the sealing ring 2 into the hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com