Double-scraper toroidal valve core and ball valve

A double-scraper and toroidal technology is applied to valve details, valve devices, and valve housing structures. It can solve the problems of small opening, small material flow area, and long flushing time, and achieve long service life, reduced speed, and increased speed. The effect of high flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings.

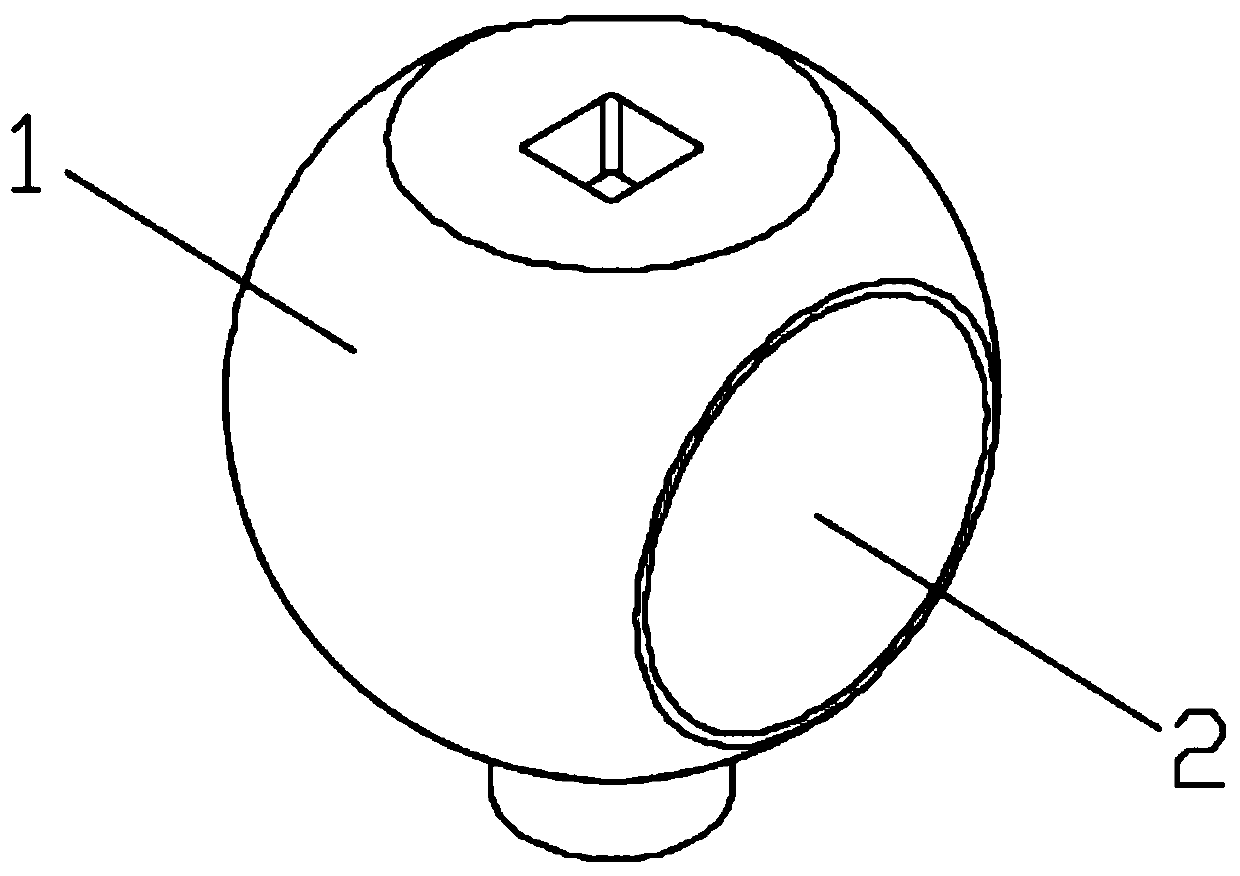

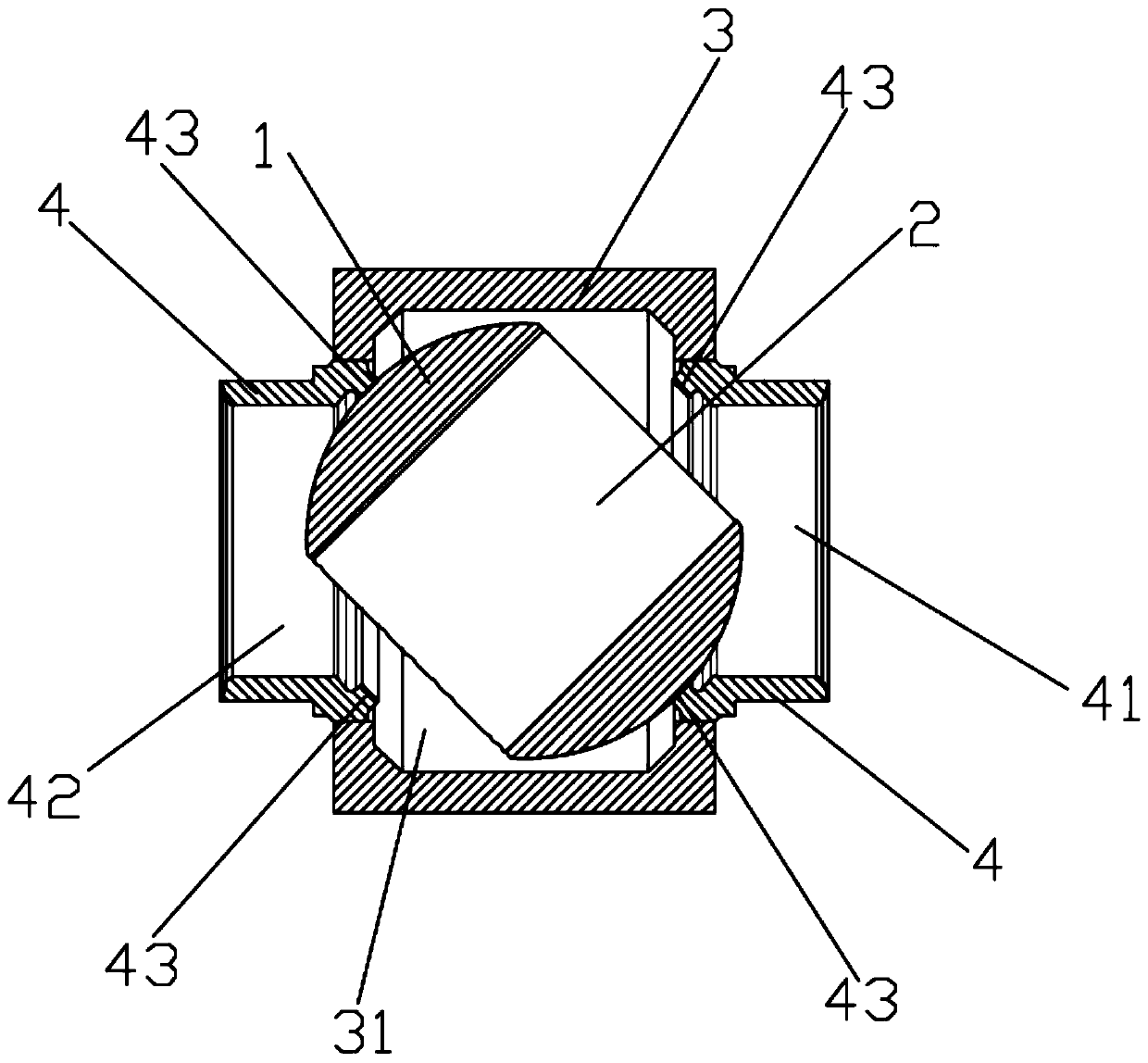

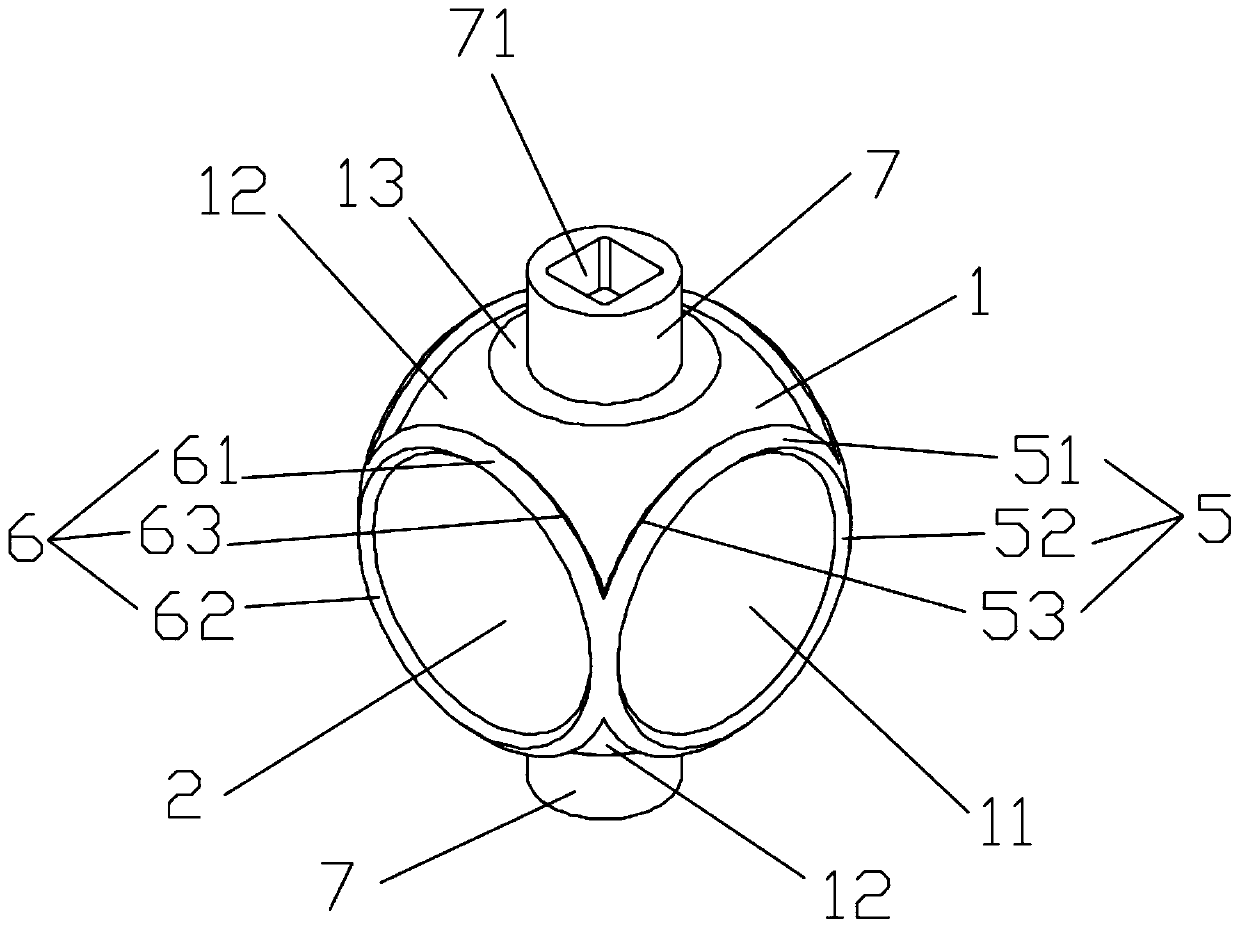

[0043] Such as Figure 3-Figure 16 The embodiment of the double scraper toroidal valve core disclosed in the present invention is shown, including a spherical core body 1, a fully open sealing ring 6, a fully closed sealing ring 5 and a supporting shaft 7. The spherical core body 1 can be selected from existing spherical or non-spherical The spherical core body 1 is rotatably installed in the valve cavity 31. The core body 1 has a material passage 2 for material circulation. The material passage 2 penetrates the core body 1 and is formed on the surface of the core body 1 The channel opening, the channel opening is preferably a round opening, the material channel 2 is preferably a cylindrical channel with both ends penetrating, the fully open sealing ring 6 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com