Large-flow high-pressure one-way valve for ship

A high-pressure check valve and high-flow technology, which is applied in the field of hydraulic valve parts, can solve the problems of high energy loss and low efficiency of the flowing medium, and achieve the effects of improving flow efficiency, reducing energy loss, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

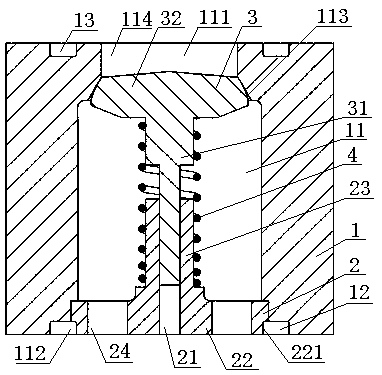

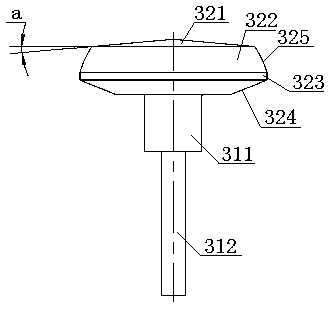

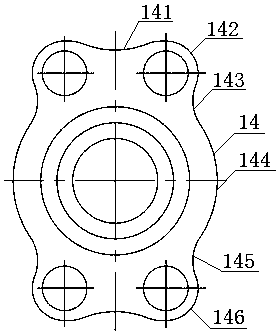

[0051] see Figure 1 to Figure 4 , a marine high-flow high-pressure one-way valve, including a valve seat 1, a spring seat 2, a valve core 3 and a spring 4 located in the inner cavity 11 of the valve seat 1, and the outer contour of the valve seat 1 is composed of two groups of structures A circular structure formed by symmetrical connection of consistent arc groups 14. The arc groups 14 include sequentially connected No. 1 concave arc 141, No. 1 convex arc 142, No. 2 concave arc 143, and No. 2 convex arc. Arc 144, No. 3 concave arc 145, No. 3 convex arc 146, the radius of curvature of the No. 1 concave arc 141 is 20-22 mm, the No. 1 convex arc 142, No. 3 convex arc The radius of curvature of the line 146 is 10-12 mm, the radius of curvature of the No. 2 concave arc 143 and No. 3 concave arc 145 is 7.5-8.5 mm, and the radius of curvature of the No. 2 convex arc 144 is 24 mm. ~28mm, and the No. 1 concave arc 141, No. 1 convex arc 142, No. 2 concave arc 143, No. 2 convex arc 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com