Improved pneumatic vectoring nozzle structure with function of injecting double secondary flow branches

A technology of vector nozzle and secondary flow, applied in the direction of machine/engine, jet propulsion device, etc., can solve the problems of reduced engine flow and reduced thrust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

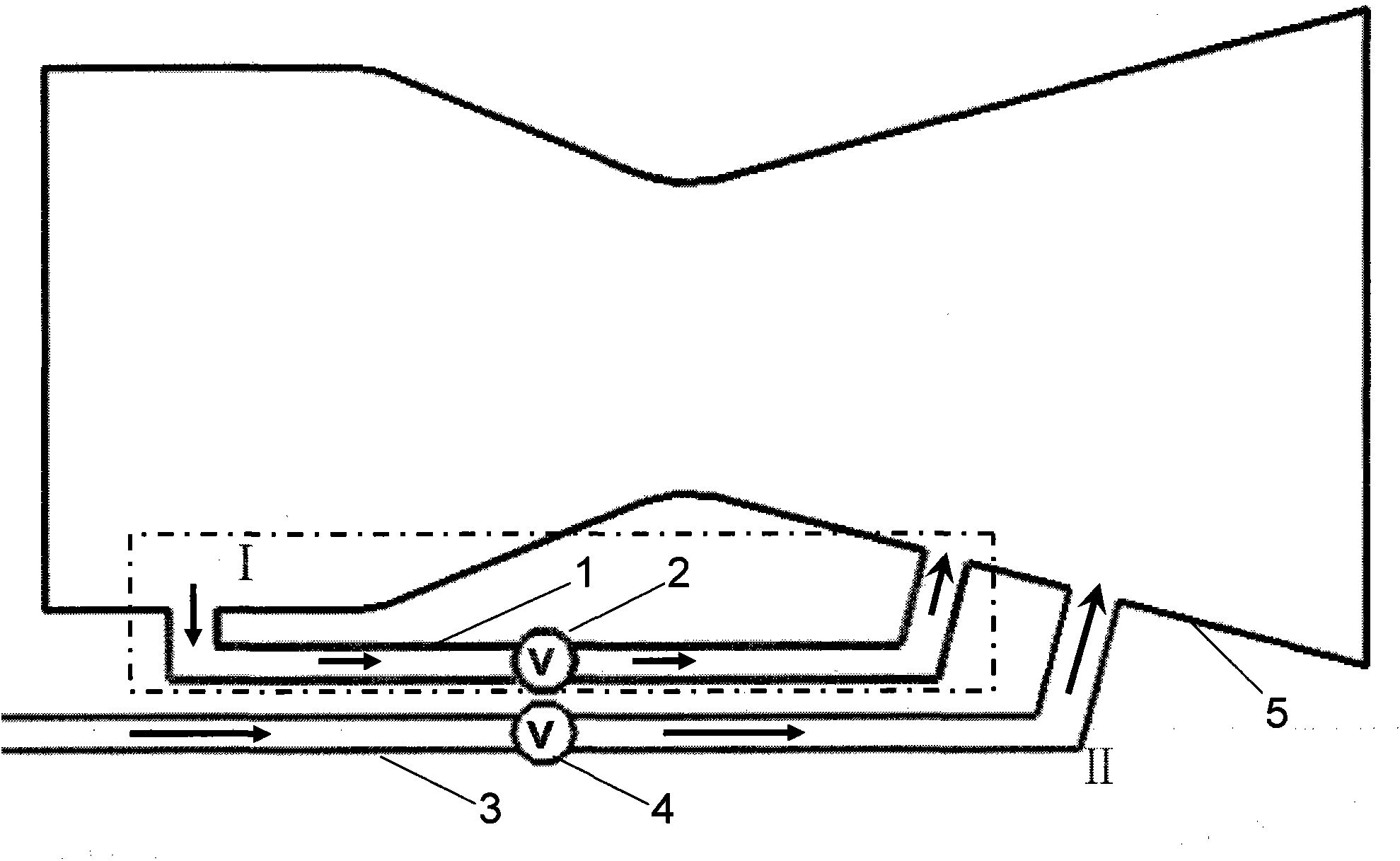

[0009] With reference to each figure, this a kind of aerodynamic vectoring nozzle structure with two secondary flow injections is characterized in that its structure comprises: the pneumatic vectoring nozzle of two secondary flow injections consists of secondary flow injection system 1, secondary The flow injection system II and the expansion nozzle 5 are composed; the secondary flow injection system I includes the bleed air pipeline 1 and the valve 2; the secondary flow injection system II includes the bleed air pipeline 3 and the valve 4;

[0010] The secondary flow injection system I bleeds air from the front end of the nozzle 5 convergence section; the secondary flow injection system II bleeds air from the high-pressure compressor of the engine; the secondary flow injection system I and the secondary flow injection system II are located on the same plane, and the secondary The flow injection system II is positioned at the bottom of the secondary flow injection system I, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com