Pilot operated axial flow valve

An axial flow valve and pilot-operated technology, which is applied in the direction of valve lift, valve details, valve device, etc., can solve problems such as difficulty in the application of various actuators, inflexible coordination of actuators, and complex structure of axial flow valves. Simple, small drag coefficient and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

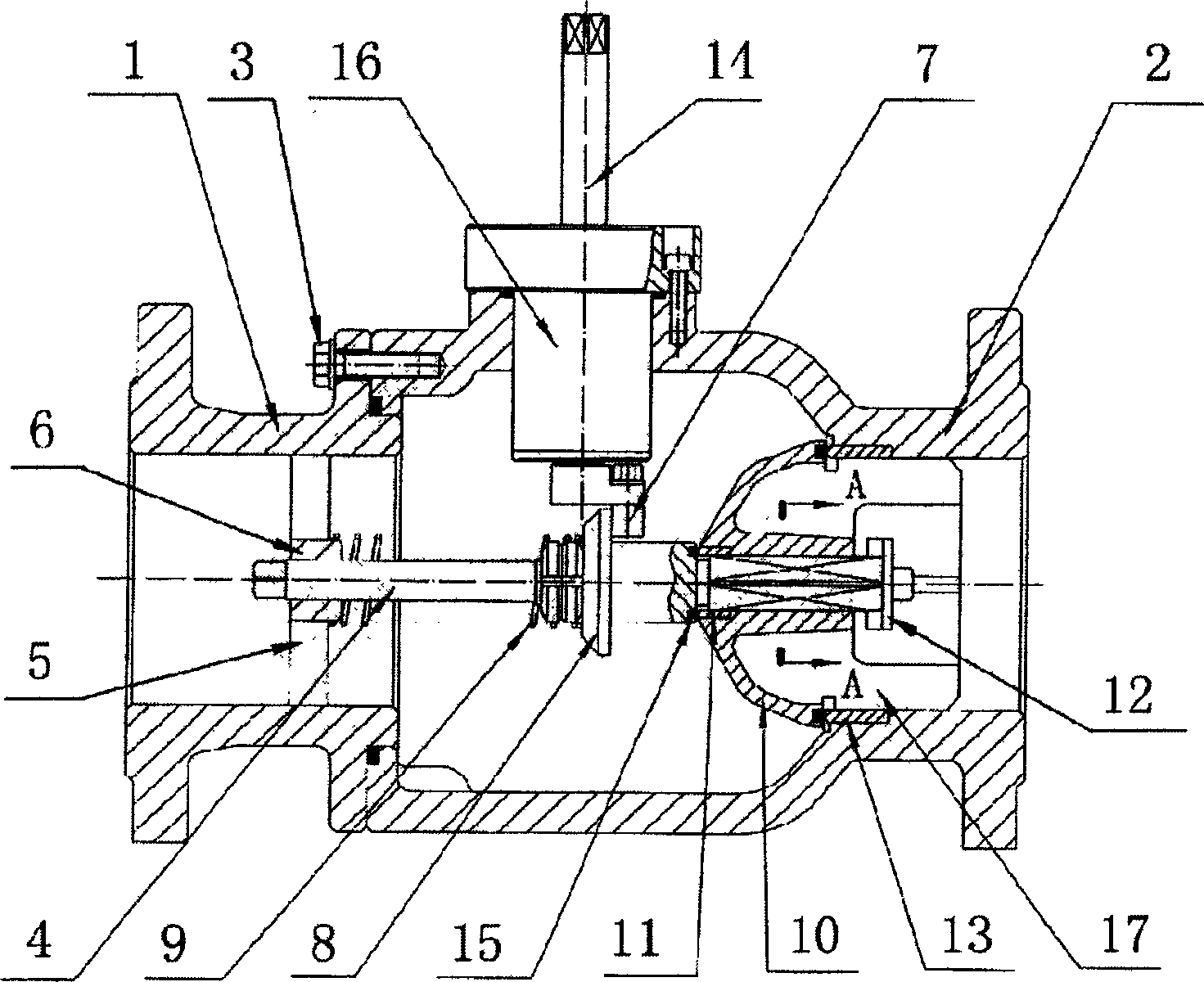

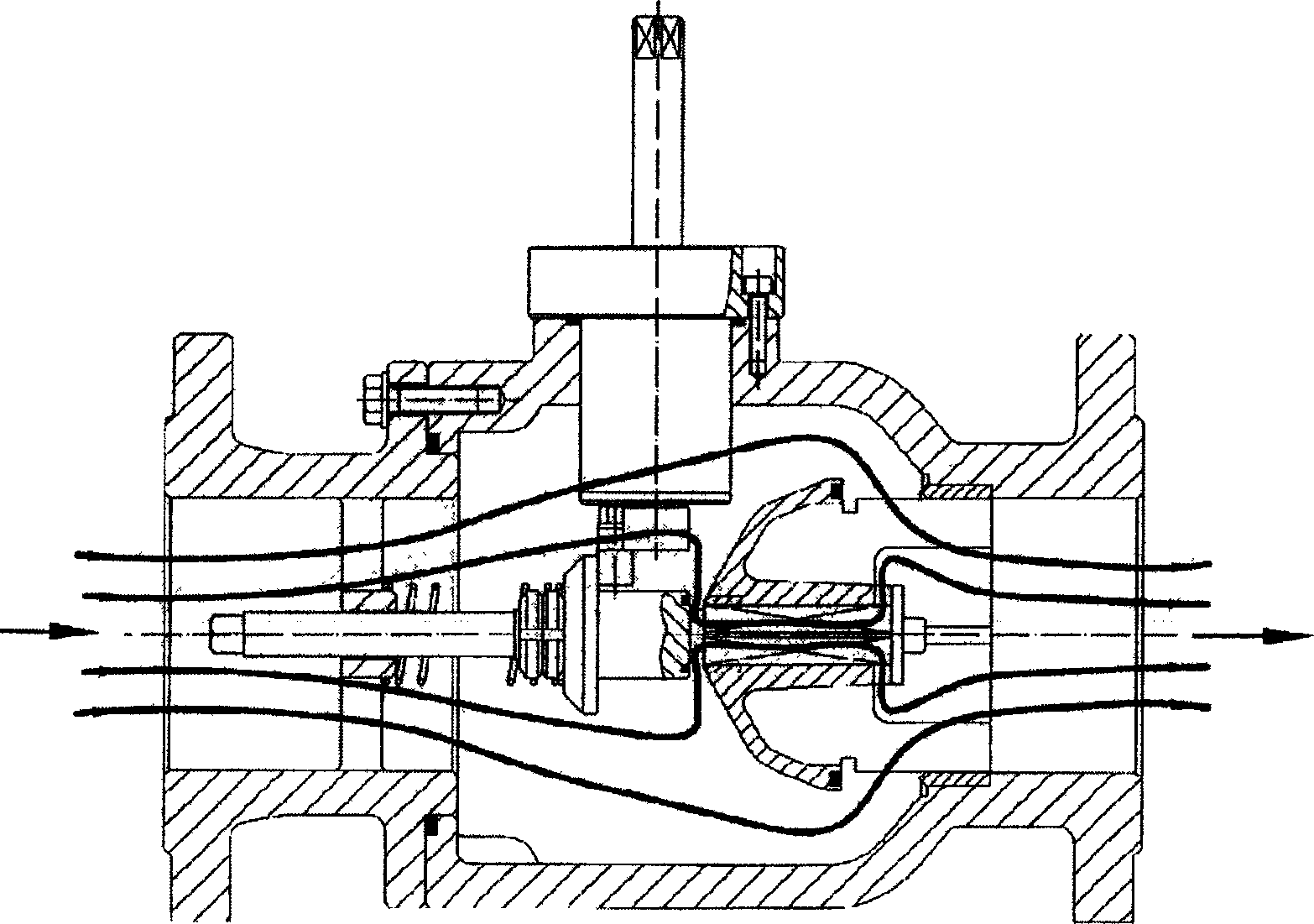

[0026] see figure 1 , the movement of the fluid flows along the direction of the common axis from the valve inlet to the valve outlet. The two outer streamlines farther from the axis indicate that the fluid flows out from the main valve seat, and the inner two streamlines closer to the axis indicate that the fluid flows from the pilot valve. Seat outflow. When the main valve disc is in the closed state, there is pressure fluid in the valve body, and the pressure acts on the main valve disc to make the opening force of the valve disc great. Therefore, when the valve stem is pulled to the left, the pilot valve disc will act first, and the pilot valve disc will move first. The action area is relatively small, so it is easy to pull, and the fluid flows downstream through the opened pilot valve disc. In this way, the pressure difference at both ends of the main valve disc can be reduced, and the main valve disc will also be opened if the valve stem is continued to be pulled.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com