Drive piezo injector unit

A fuel injector, piezoelectric technology, applied in the direction of circuit devices, battery circuit devices, collectors, etc., can solve the problem that the work of the fuel injector is affected, it is difficult to ensure the stability and reliability of the fuel injector, and the power consumption of the system is high. problems, to achieve the effect of improving stability and reliability, compact structure, and high precision of current control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with specific drawings and embodiments.

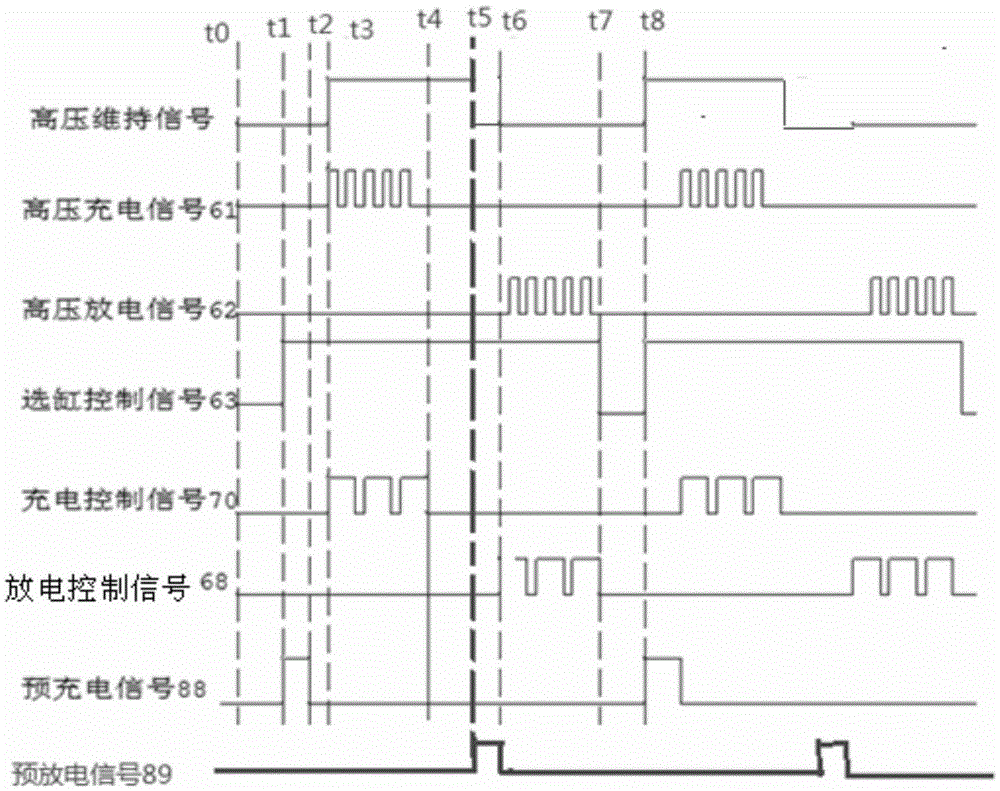

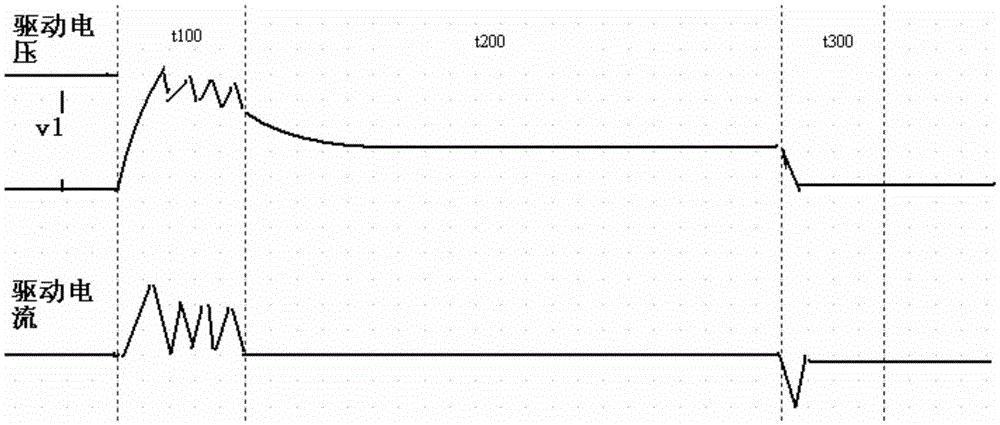

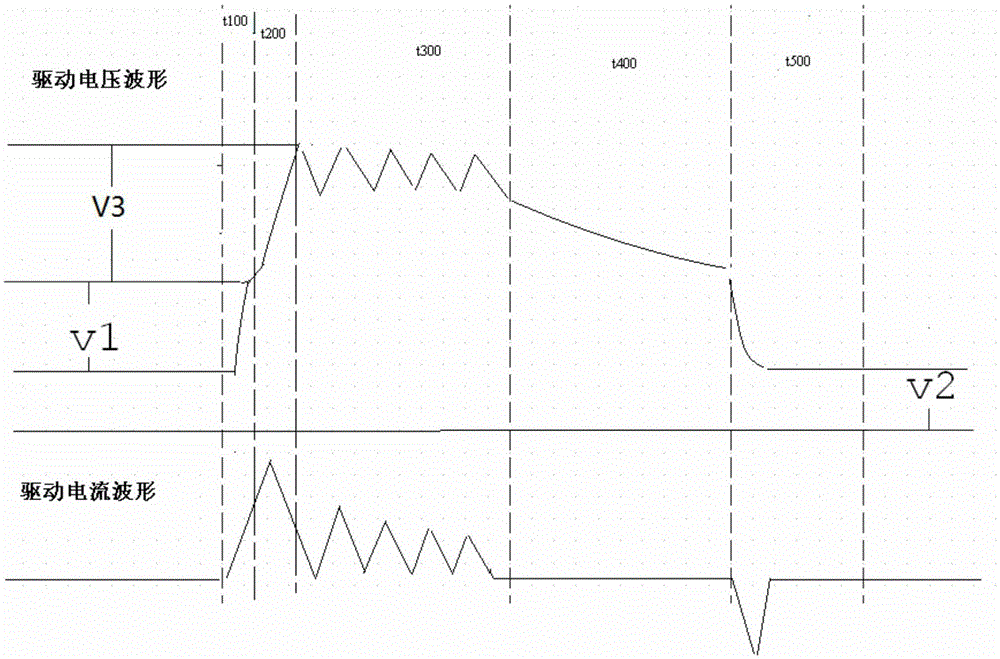

[0041] Such as figure 1 As shown: In order to effectively control the working process of the piezoelectric actuator 91, reduce the power consumption of the system, and reduce the influence of the dielectric loss on the fuel injector under complex working conditions, the present invention includes multiple piezoelectric actuators connected in parallel 91; the piezoelectric actuator 91 is connected to the actuator drive circuit module 3, and the actuator drive circuit module 3 includes a switch tube M2, a switch tube M3, and a switch tube M4 that is consistent with the number of the piezoelectric actuator 91; The drain of the switching tube M2 is connected to the output end of the high-voltage DCDC module 1 for providing the driving voltage required by the piezoelectric actuator 91, the source terminal of the switching tube M2 is connected to the drain terminal o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com