Silicon carbide based high-power low-voltage large-current-output direct-current power supply

A DC power supply and high-power technology, applied in the direction of converting AC power input to DC power output, high-efficiency power electronic conversion, and output power conversion devices, can solve problems such as low power density, low switching frequency, and low system efficiency. Achieve the effects of improving current control accuracy, power density, and system efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

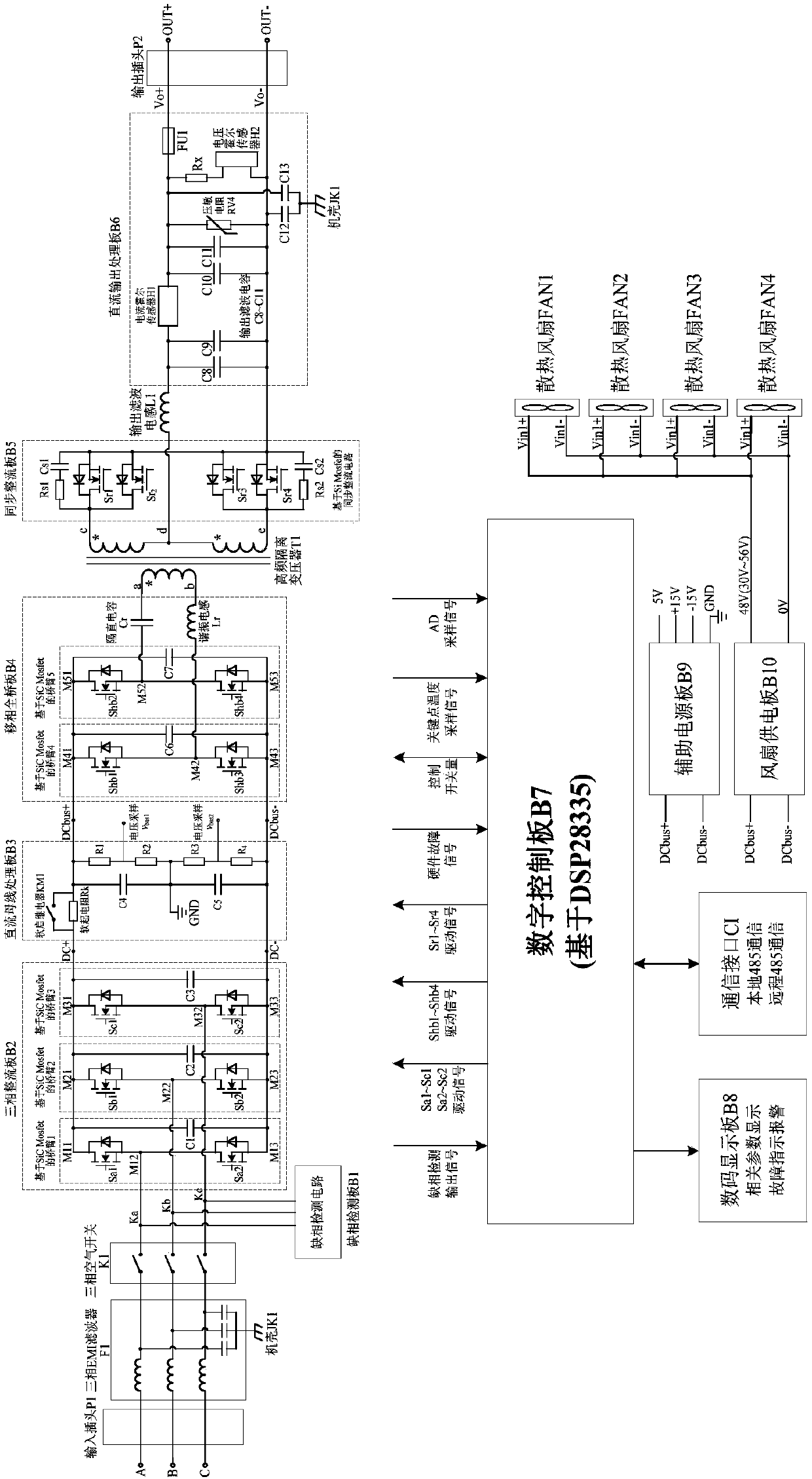

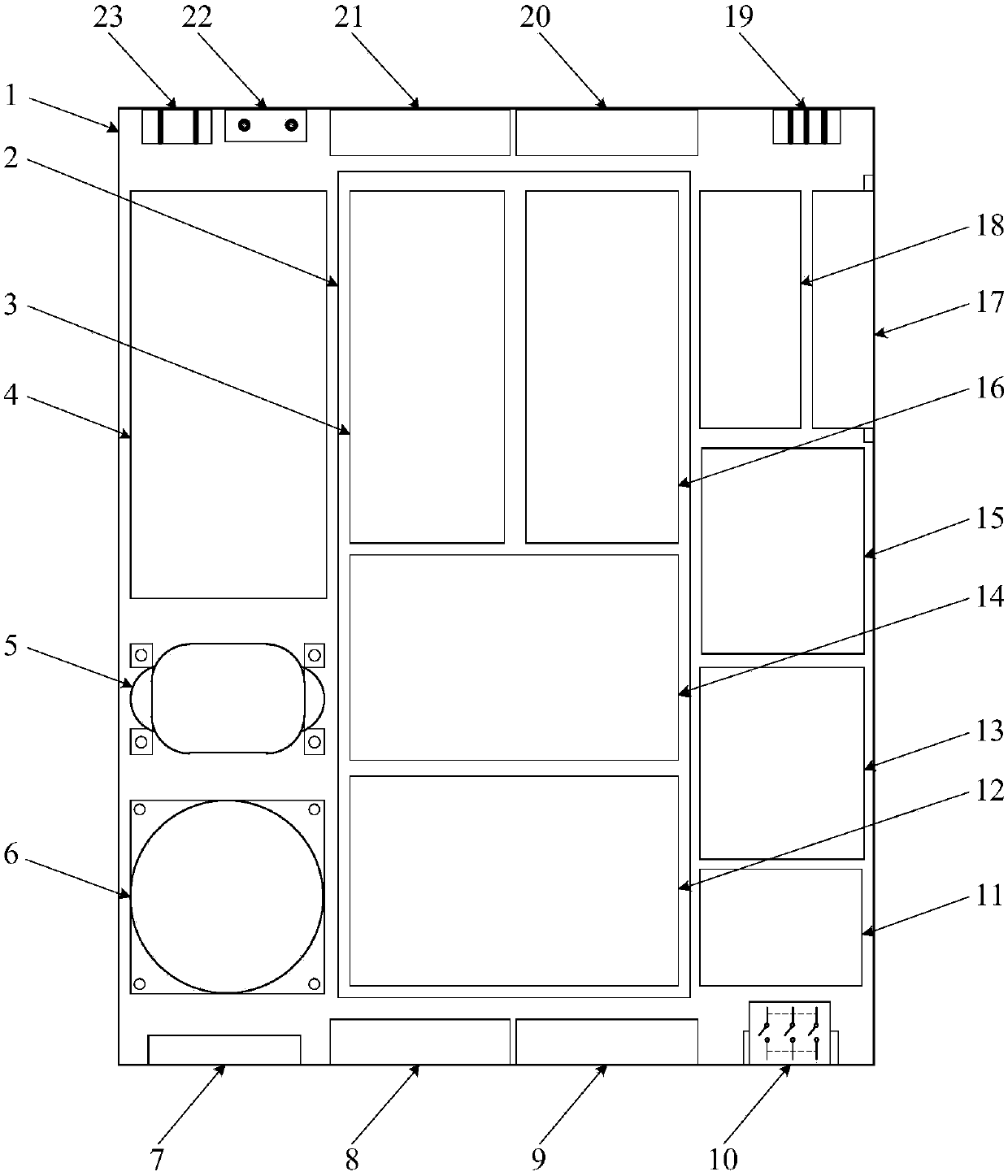

[0012] see Figure 1-2 , the present invention provides a technical solution: a high-power low-voltage high-current output DC power supply based on silicon carbide, including: input plug P1 19, three-phase EMI filter F1 17, three-phase air switch K1 10, phase loss detection board B1 11, three-phase rectification board B2 12, DC bus processing board B3 13, phase shifting full bridge board B4 14, high frequency isolation transformer T1 6, synchronous rectification board B5 3, output filter inductor L1 5, DC output processing board B6 4 , output plug P2 23, digital control board B716, digital display board B8 7, communication interface CI 22, auxiliary power supply board B9 15, fan power supply board B10 18, cooling fan FAN18, cooling fan FAN2 9, coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com