Method for catalyzing hydrodeoxygenation to prepare hydrocarbon through guaiacol

A technology of guaiacol and catalytic deoxygenation, which is applied in the preparation of liquid hydrocarbon mixtures, the petroleum industry, biological raw materials, etc., can solve the problems of harsh reaction conditions, catalyst deactivation production costs, etc., and achieve low production costs and reduce oxygen content Productivity of similar substances, the effect of conventional and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

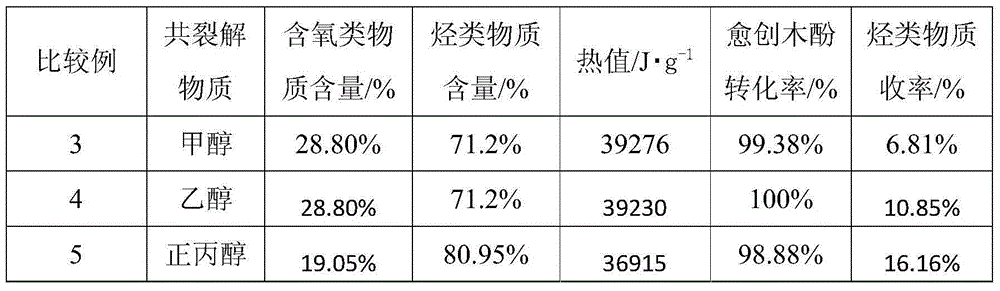

Embodiment 1

[0025] (1) 15g guaiacol and 15g n-butanol are mixed homogeneously, stand-by;

[0026] (2) Fill 30g of catalyst HZSM-5 molecular sieve into the tubular fixed-bed reactor, and fix it with a screen, so that all the catalysts are in the constant temperature section of the reactor, and then evenly lay 10g of quartz on the upper layer of the catalyst sand;

[0027] (3) Seal the fixed bed reactor and place it in the electric heating jacket. The insulation jacket has both heating and heat preservation functions. After the electric heating jacket is turned on to heat the reactants in the fixed bed reactor to 550°C, the peristaltic pump at 0.68h -1 The mass space velocity transports the mixed solution obtained in step (1) to the fixed-bed reactor, and after the addition is completed, the insulation reaction is continued for 0.5 hours. During the reaction process, a serpentine condenser tube is used to condense the reaction product, the non-condensable gas is collected into the gas col...

Embodiment 2

[0035] (1) 15g guaiacol and 30g n-amyl alcohol are mixed evenly, stand-by;

[0036] (2) Fill 15g of catalyst HZSM-5 molecular sieve into the tubular fixed bed reactor, and fix it with a screen, so that all the catalysts are in the constant temperature section of the reactor, and then evenly lay 18g of quartz on the upper layer of the catalyst sand;

[0037] (3) Seal the fixed bed reactor and put it in the electric heating jacket. The insulation jacket has both heating and heat preservation functions. After the electric heating jacket is turned on to heat the reactants in the fixed bed reactor to 500°C, the peristaltic pump at 0.4h -1 The mass space velocity is used to transport the mixed solution obtained in step (1) to the fixed bed reactor, after the addition is completed, continue the heat preservation reaction for 0.8 hours. During the reaction process, a serpentine condenser tube is used to condense the reaction product, the non-condensable gas is collected into the gas...

Embodiment 3

[0040] (1) 20g of guaiacol and 10g of n-butanol are mixed evenly and set aside;

[0041] (2) Fill 24g of catalyst HZSM-5 molecular sieve into the tubular fixed bed reactor, and fix it with a screen, so that all the catalysts are in the constant temperature section of the reactor, and then evenly lay 15g of quartz on the upper layer of the catalyst sand;

[0042] (3) Seal the fixed bed reactor and place it in the electric heating jacket. The insulation jacket has both heating and heat preservation functions. After the electric heating jacket is turned on to heat the reactants in the fixed bed reactor to 600°C, the peristaltic pump for 1.5h -1 The mass space velocity transports the mixed solution obtained in step (1) to the fixed-bed reactor, and after the addition is completed, continue the heat preservation reaction for 1 hour. During the reaction process, a serpentine condenser tube is used to condense the reaction product, the non-condensable gas is collected into the gas ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Calorific value | aaaaa | aaaaa |

| Calorific value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com