Steel plate splicing welding joint bottom-surface ceramic liner lifting device and operation method thereof

A technology of ceramic gaskets and splicing welds, which is applied in auxiliary devices, welding/welding/cutting items, welding equipment, etc. Difficulty of operation and construction cost, improving installation efficiency and avoiding unfavorable factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

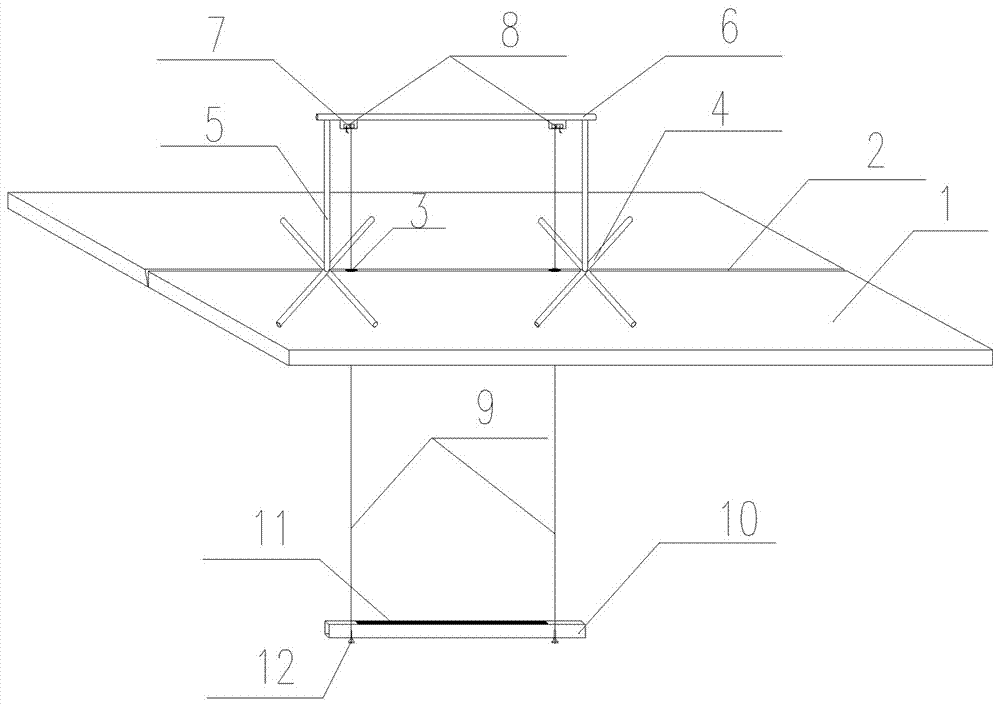

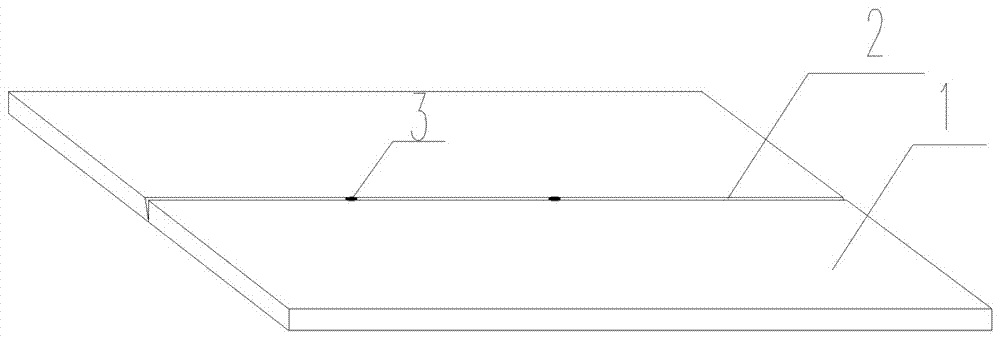

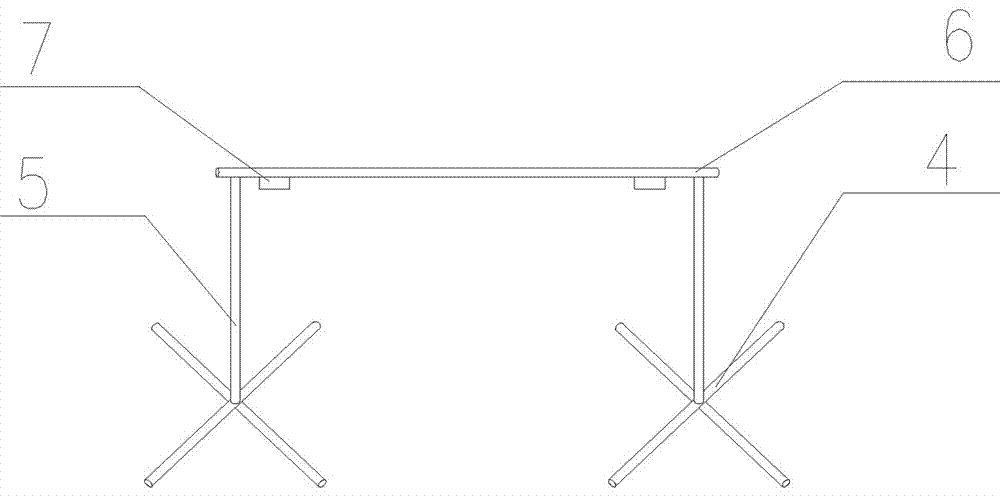

[0029] Such as Figure 1~7 As shown, a ceramic liner lifting device on the bottom surface of the steel plate splicing weld includes a lifting hanger installed on the upper surface of the welded steel plate 1, a lifting device fixedly connected with the lifting hanger and passing through the steel plate weld 2, and a lifting device installed on the lifting device. The pad bracket 10 at the bottom; the lifting hanger includes a crossbar 6 horizontally arranged above the welded steel plate 1, two columns 5 vertically fixedly connected to the two ends of the crossbar 6 and a stable base frame 4 provided at the bottom of the column 5 , the stable base frame 4 is erected on the upper surface of the welded steel plate 1; the lifting device includes two sets of pulley assemblies connected to both ends of the cross bar 6 and steel wire ropes 9 respectively connected to each set of pulley assemblies, and the steel wire ropes 9 pass through The plate hole 3 at the welding seam 2 of the s...

Embodiment 2

[0034] The operation steps of the installation method of the ceramic liner lifting device on the bottom surface of the spliced weld seam of the steel plate in embodiment 1.

[0035] Lift hanger design:

[0036] According to the actual needs of the project, determine the size and other conditions of the lifting hanger to ensure the strength and stability of the hanger;

[0037] Lifting device design:

[0038] According to the maximum lifting height, hoisting weight and other conditions, select the appropriate lifting pulley and wire rope, design and rigidly fix the upper hanger, and the steel wire rope is hinged with the lower fixed beam to ensure reliable connection, and analyze and design weak nodes.

[0039] Operation method:

[0040] Assemble the hoisting hanger, hoisting device and lower liner bracket on site, and after the overall commissioning and operation of the mechanism is complete, the liner will be formally lifted and installed in place.

[0041] First, the br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com