Pile driving model test device based on soil plugging effect and application of pile driving model test device

A model test device and pile driving technology, which are applied in the test of foundation structure, construction, foundation structure engineering, etc., can solve the problems of combining soil plug and pile body, unable to simulate the dynamic response of soil around the change of soil plug, etc. Accurate testing and accurate experimental results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

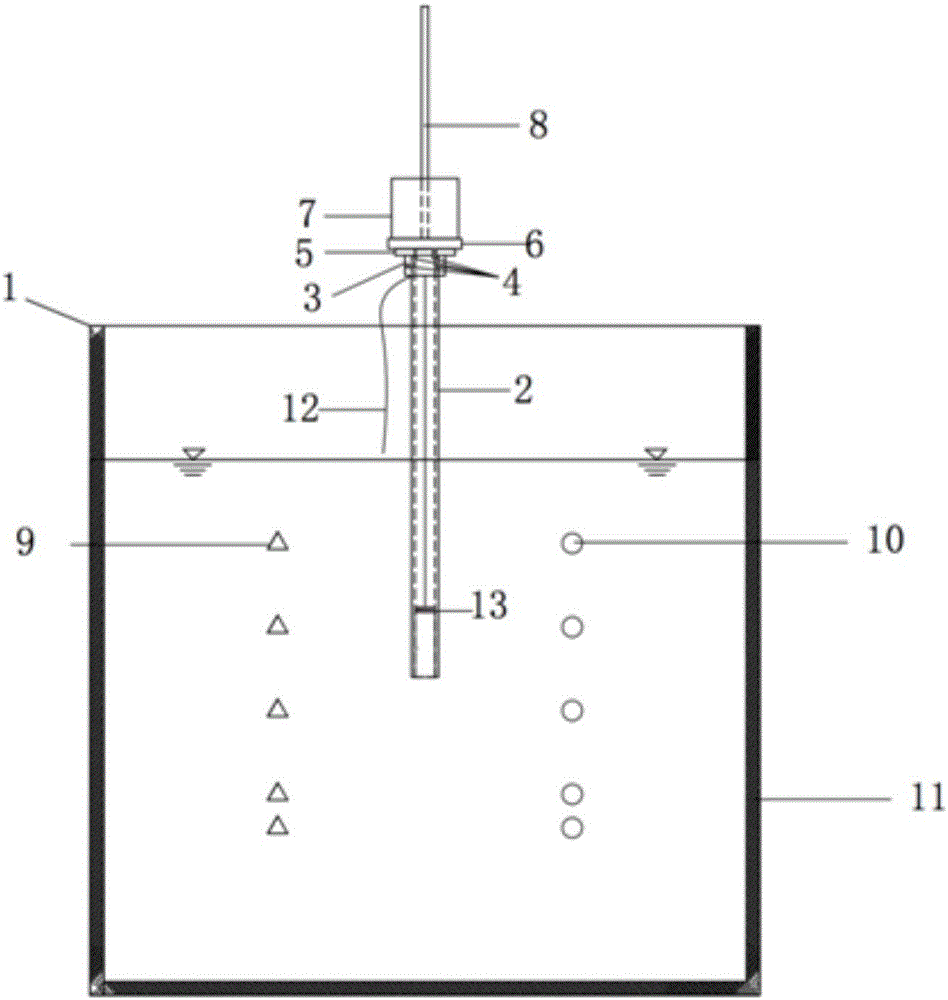

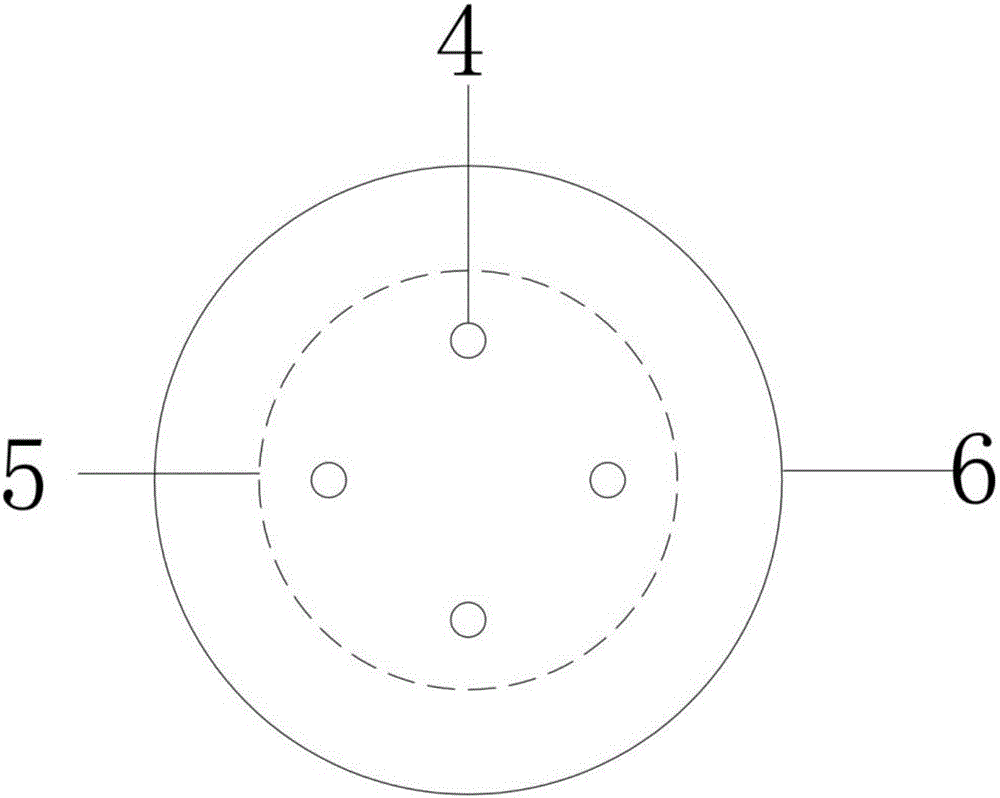

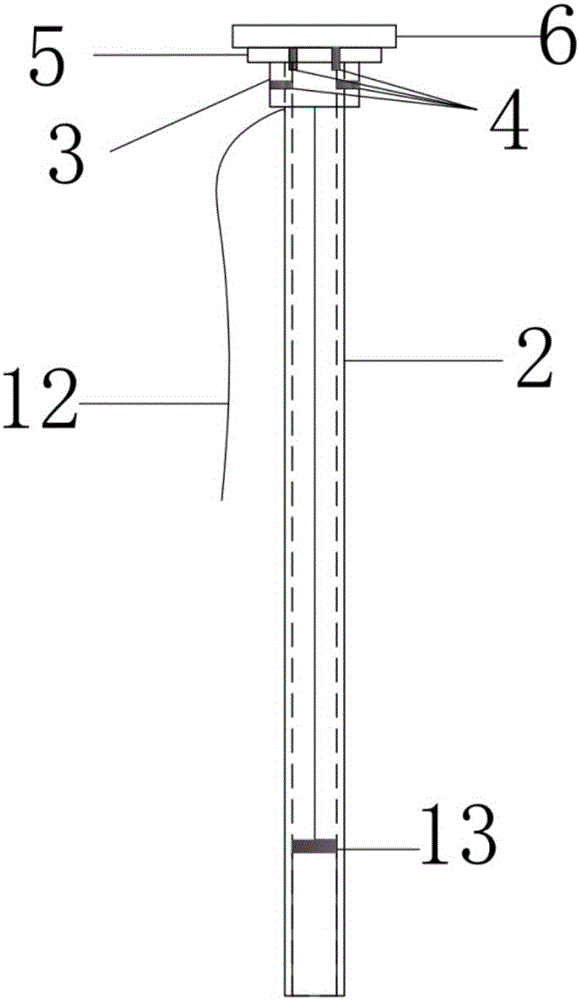

[0030] A pile sinking model test device considering the soil plugging effect, such as figure 1 As shown, it includes a model box 1, an open pipe pile 2, a guide rod 8 and a piercing hammer 7. The inside of the model box 1 is filled with a sand sample, and a miniature earth pressure gauge 10 and an acceleration sensor 9 connected to a data acquisition instrument are embedded in the sand sample. The earth pressure gauge 10 and the acceleration sensor 9 are layered in the sand sample of the model box 1, the open pipe pile 2 is vertically arranged in the center of the model box 1, and the guide rod 8 is vertically arranged at the upper end of the open pipe pile 2, and the The hammer 7 passes through the guide rod 8 and is located at the top of the open pipe pile 2. A pile cap 3 is arranged between the open pipe pile 2 and the guide rod 8. The center of the pile cap 3 is provided with a hole for inserting the guide rod 8. The upper part of the pile cap 3 Steel pad 5 is set, and rub...

Embodiment 2

[0034] The device described in Example 1 is used for the dynamic pile sinking model test of pipe piles, and the specific steps are as follows:

[0035] 1. Laying sand samples

[0036] After drying the sand sample, put it into the model box in layers using the falling rain method. The height of the falling sand is 50cm. According to the layout requirements of the instrument, the sand should reach the height where the instrument is buried, and the sand should be suspended and compacted.

[0037] 2. Buried sensors

[0038] Micro-earth pressure gauges and acceleration sensors are buried in the sand samples to explore the variation of soil pressure and acceleration at different depths during the pile sinking process. The embedding of sensors is arranged according to the most serious vibration effect of hammer piles on the surrounding soil, that is, earth pressure sensors and acceleration sensors are buried along the pile surface at distances of 1D, 3D, and 5D (D is the diameter of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com