Slim tube sedimentation unit and separation system and separation method of suspended particles

A technology of suspended particles and separation system, applied in the direction of sedimentation tank, etc., can solve the problem of unclear particle size of separated particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

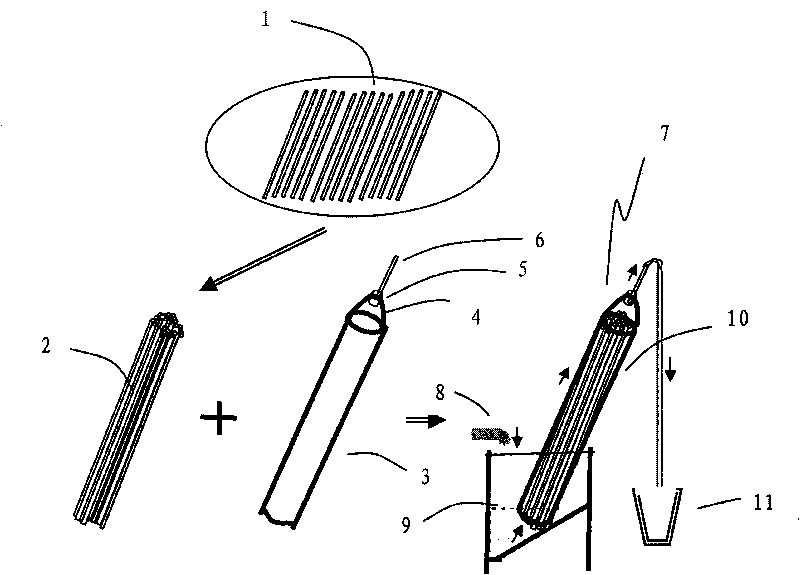

[0121] figure 1 This is the assembly diagram of the siphon separation device in Example 1 of the present invention. The siphon separation device 7 includes a muddy water storage tank 9, a thin tube settling unit 10 and a water tank 11. The above-mentioned thin tube settling unit 10 is composed of a thin settling tube 1, a sleeve 3, a sealing cover 4, a sealing plug 5, and a siphon outlet pipe 6. A plurality of thin settling tubes 1 are made into a tube bundle 2, and the tube bundle 2 is tightly formed. Insert the sleeve 3, seal the upper part of the sleeve 3 with a cone-shaped cover 4; a small hole is opened at the upper end of the cone-shaped cover 4, and a sealing plug 5 connected to the siphon outlet pipe 6 just closes it tightly. Small holes.

[0122] Insert the capillary sedimentation unit 10 into the turbid water storage tank 9 at a certain oblique angle. Under the action of the siphon, the inlet water flows in from the bottom of the capillary sedimentation unit 10, and th...

Embodiment 2

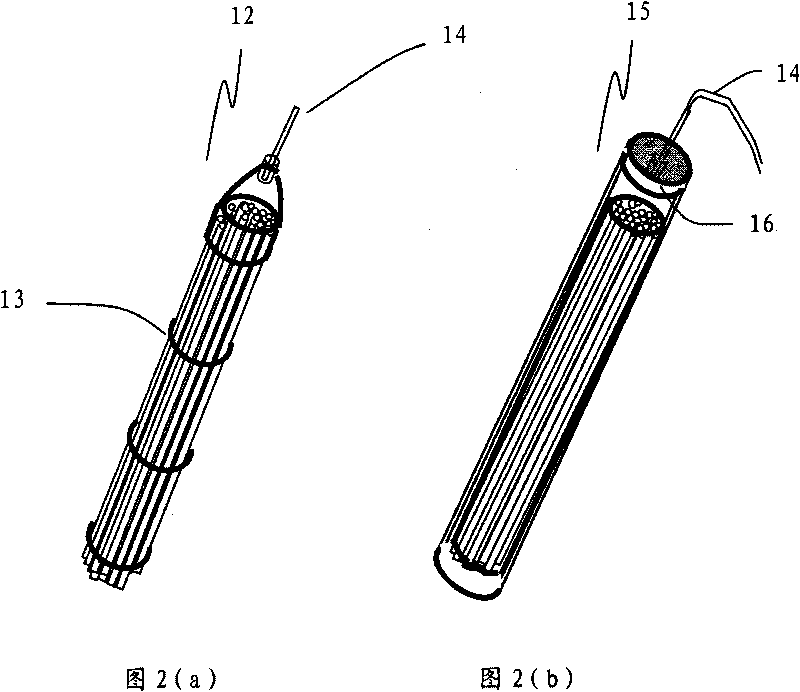

[0164] The difference between this embodiment 2 and the embodiment 1 is that a large number of thin settler pipes 1 are made into a tube bundle 2, and the tube bundle 2 is tied and fixed with a rope 13, and the upper end is sealed with a cone-shaped cover, as shown in Figure 2(a). Others are the same as in Embodiment 1.

Embodiment 3

[0166] The difference between the third embodiment and the first embodiment is that a flat cover 16 is used to seal the upper end of the settling unit, as shown in Figure 2(b). Others are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Section height | aaaaa | aaaaa |

| Tube chief | aaaaa | aaaaa |

| Tube inner diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com