Preparation method for grapheme open-tube electric chromatographic column

An electrochromatographic column and graphene technology, applied in the field of chromatography, can solve the problems of long modification time and achieve the effects of low cost, increased modification amount, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

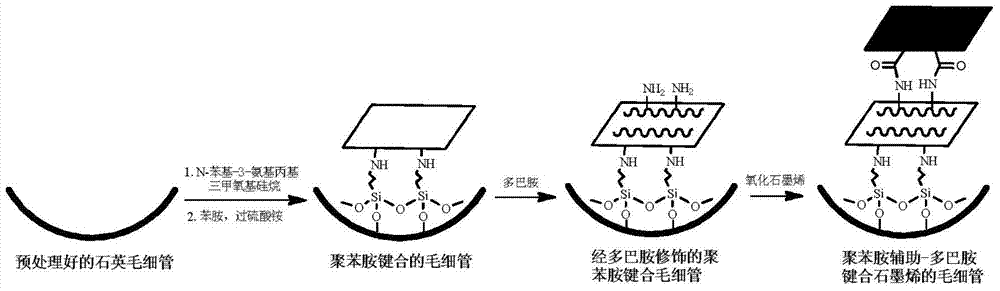

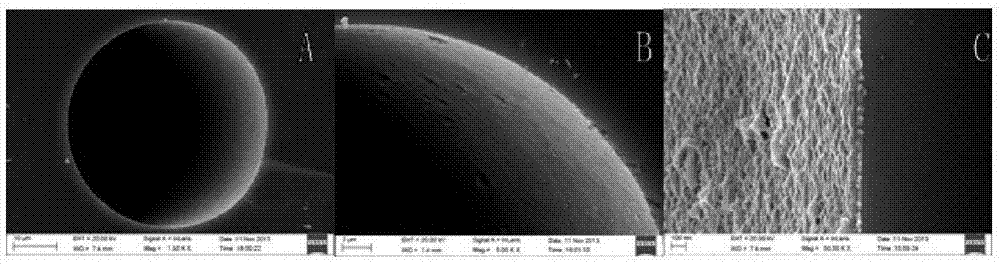

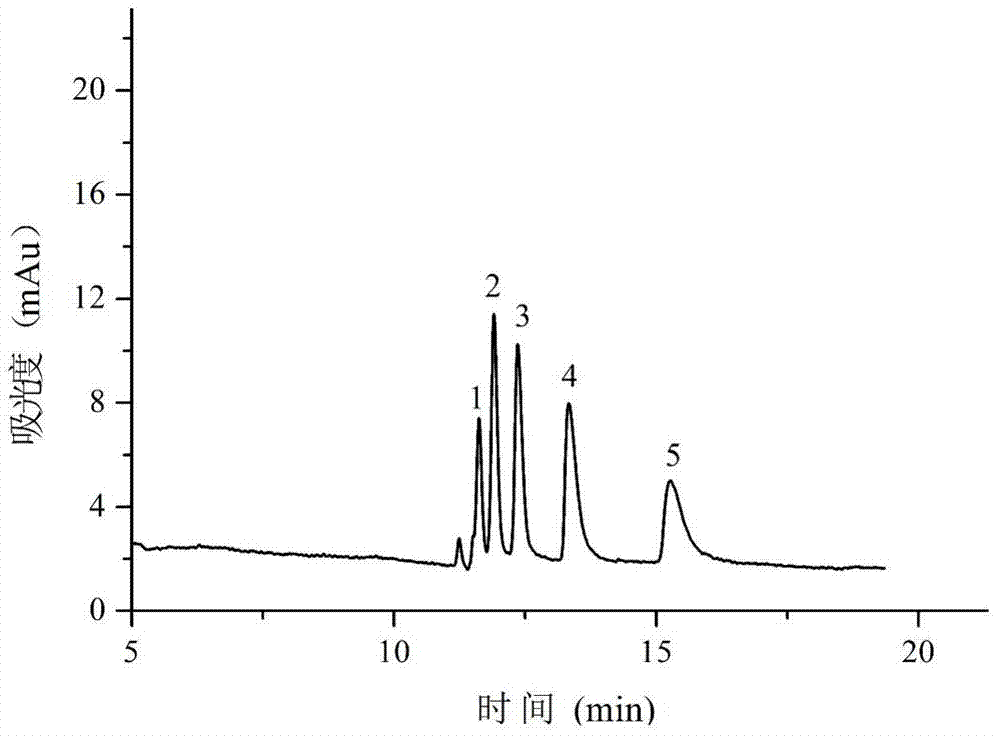

[0029] (1) Take a 60cm-long quartz capillary (50 μm i.d. × 375 μm o.d.), rinse it with 1M NaOH for 2 hours, rinse it with pure water for half an hour, and dry it with nitrogen; (2) Prepare N-phenyl-3-aminopropyl trimethyl Oxysilane ethanol solution (20%, v / v), put it into the pretreated capillary for silanization reaction, react at 60°C for 12h, wash with pure ethanol after the reaction, and blow dry with nitrogen; (3) Separately configure 0.2M aniline hydrochloric acid solution and 0.05M ammonium persulfate hydrochloric acid solution, the above two solutions were mixed in equal volumes and then quickly passed into the silanized capillary tube, reacted overnight, washed with pure water, and treated at 120 ° C for 3 hours, Obtain a capillary bonded with polyaniline; (4) Weigh 10 mg of dopamine and dissolve it in 5 mL of 10 mM Tris buffer, adjust the pH value to 8.5, shake the prepared dopamine solution for 10 minutes, and then dissolve it at a flow rate of 0.05 mL / h Continuousl...

Embodiment 2

[0032] (1) Take a 60cm-long quartz capillary (50 μm i.d. × 375 μm o.d.), rinse it with 1M NaOH for 2 hours, rinse it with pure water for half an hour, and dry it with nitrogen; (2) Prepare N-phenyl-3-aminopropyl trimethyl Oxysilane ethanol solution (20%, v / v), put it into the pretreated capillary for silanization reaction, react at 60°C for 24h, wash with pure ethanol after the reaction, and blow dry with nitrogen; (3) Separately configure 0.2M aniline hydrochloric acid solution and 0.05M ammonium persulfate hydrochloric acid solution, the above two solutions were mixed in equal volumes and then quickly passed into the silanized capillary tube, reacted overnight, washed with pure water, and treated at 120 ° C for 3 hours, A capillary bonded with polyaniline is obtained; (3′) repeating the polyaniline modification step once to obtain a double-layer polyaniline modified capillary. (4) Weigh 10 mg of dopamine and dissolve it in 5 mL of 10 mM Tris buffer, adjust the pH to 8.5, sha...

Embodiment 3

[0036] (1) Take a 60cm-long quartz capillary (50 μm i.d. × 375 μm o.d.), rinse it with 1M NaOH for 2 hours, rinse it with pure water for half an hour, and dry it with nitrogen; (2) Prepare N-phenyl-3-aminopropyl trimethyl Oxysilane ethanol solution (50%, v / v), put it into the pretreated capillary for silanization reaction, react at 60°C for 12h, wash with pure ethanol after the reaction, and blow dry with nitrogen; (3) Separately configure 0.2M aniline hydrochloric acid solution and 0.05M ammonium persulfate hydrochloric acid solution, the above two solutions were mixed in equal volumes and then quickly passed into the silanized capillary tube, reacted overnight, washed with pure water, and treated at 120 ° C for 3 hours, Obtain a capillary bonded with polyaniline; (4) Weigh 10 mg of dopamine and dissolve it in 5 mL of 10 mM Tris buffer, adjust the pH value to 8.5, shake the prepared dopamine solution for 10 minutes, and then dissolve it at a flow rate of 0.05 mL / h Continuousl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com