Tube case heat exchange system and heat exchanger

A shell-and-tube heat exchanger and heat exchanger technology, applied in the field of heat exchange, can solve problems such as high flow rate, easy leakage of hydrogen gas, high flow rate, etc., achieve good safety, increase heat exchange effect, and ensure safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

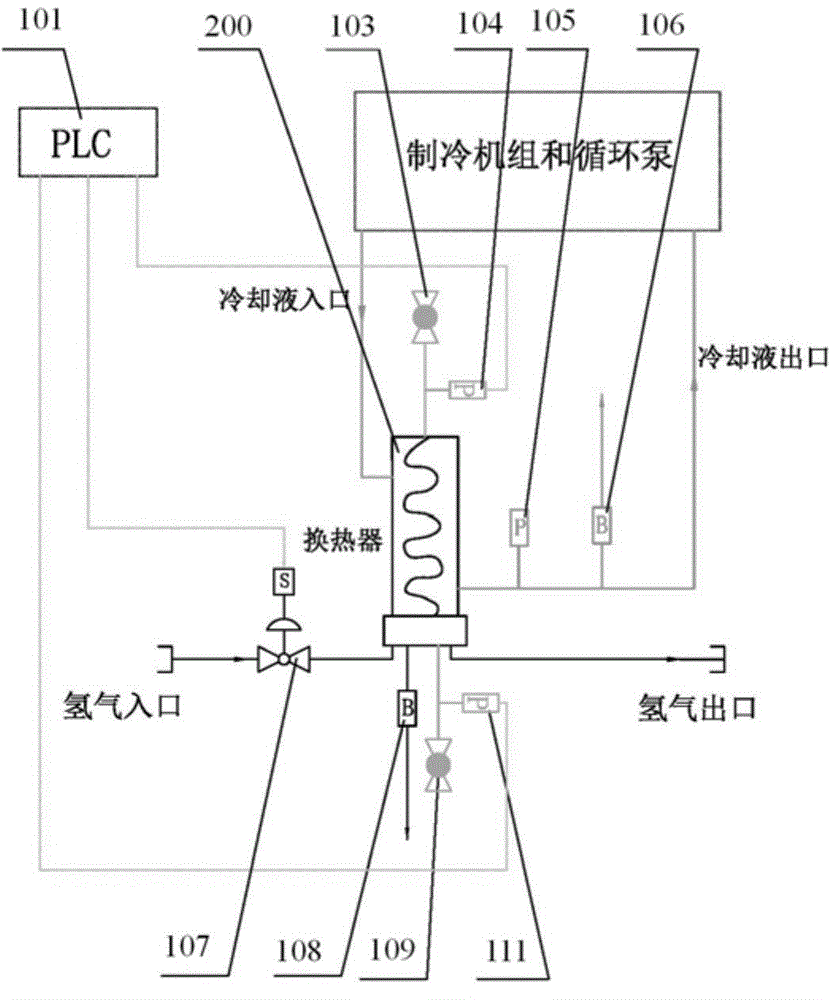

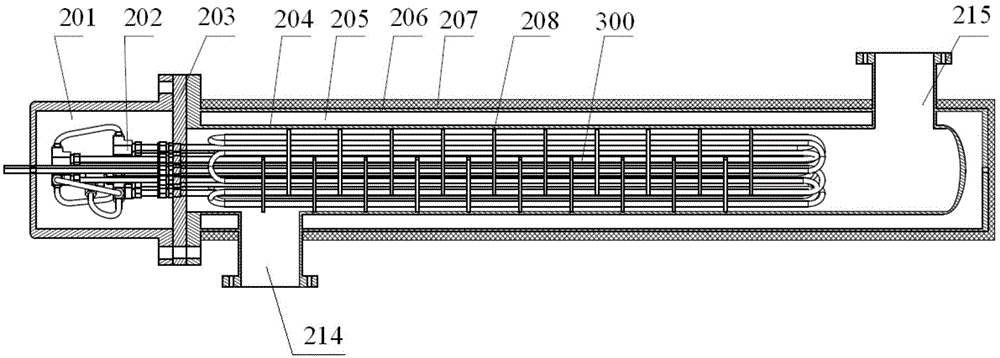

[0045] Such as figure 1As shown, the present invention discloses a shell-and-tube heat exchange system, which includes, for example, a shell-and-tube heat exchanger 200, an inner tank pressure monitoring and protection module connected to the shell-and-tube heat exchanger 200, a cover pressure monitoring and The protection module and the heat exchanger 200 liner vacuum insulation layer pressure monitoring module, the liner pressure monitoring and protection module, the cover pressure monitoring and protection module, and the heat exchanger inner liner vacuum insulation layer pressure monitoring module share PLC101 and solenoid valves 107.

[0046] Among them, the inner tank pressure monitoring and protection module is composed of inner tank pressure sensor 105 installed on the inner tank coolant outlet 214 circuit of heat exchanger 200, inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com