Selenium precursor fluid and method for preparing cadmium selenide or zinc selenide quantum dots by using the same

A technology of precursor liquid and quantum dots, which is applied in the direction of chemical instruments and methods, luminescent materials, etc., can solve the problems of high cost of alkylphosphine process, high cost of phosphine-free process, danger of environmental pollution, etc., and achieve good crystallinity and compatibility Good, high volumetric yield results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] 1. Preparation of Se precursor solution

[0035] Take 0.100 g of selenium powder and add it to 4 ml of oleoyl morpholine, heat it to 220-230 ° C under the protection of Ar gas, and keep it warm for 1 hour to obtain a completely transparent brown-red solution. Stop heating, and continue cooling to room temperature under the protection of Ar gas. Set aside.

[0036] 2. Synthesis of CdSe quantum dots and ZnSe quantum dots

[0037] (1) Preparation of cadmium selenide in oleoylmorpholine medium

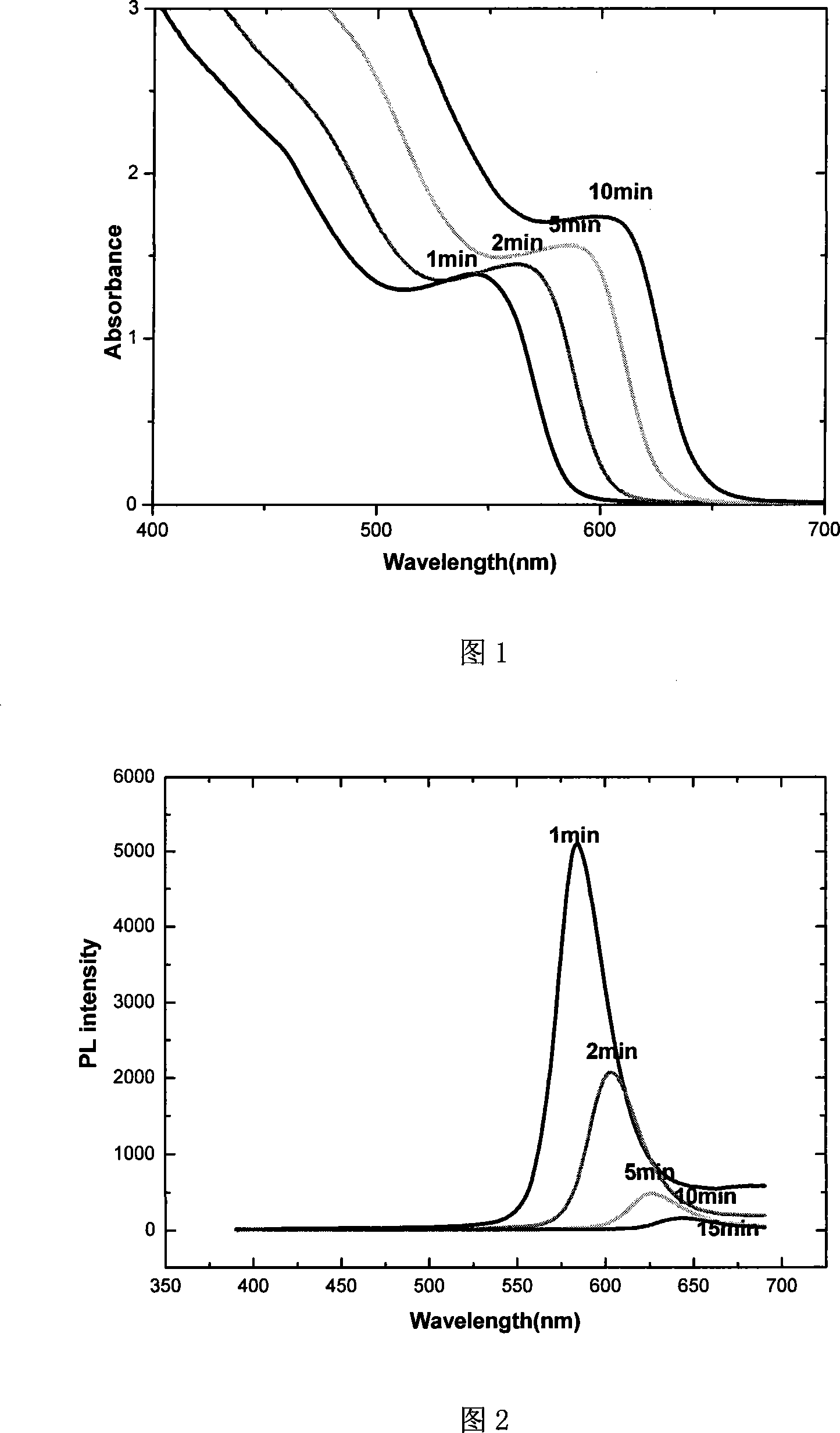

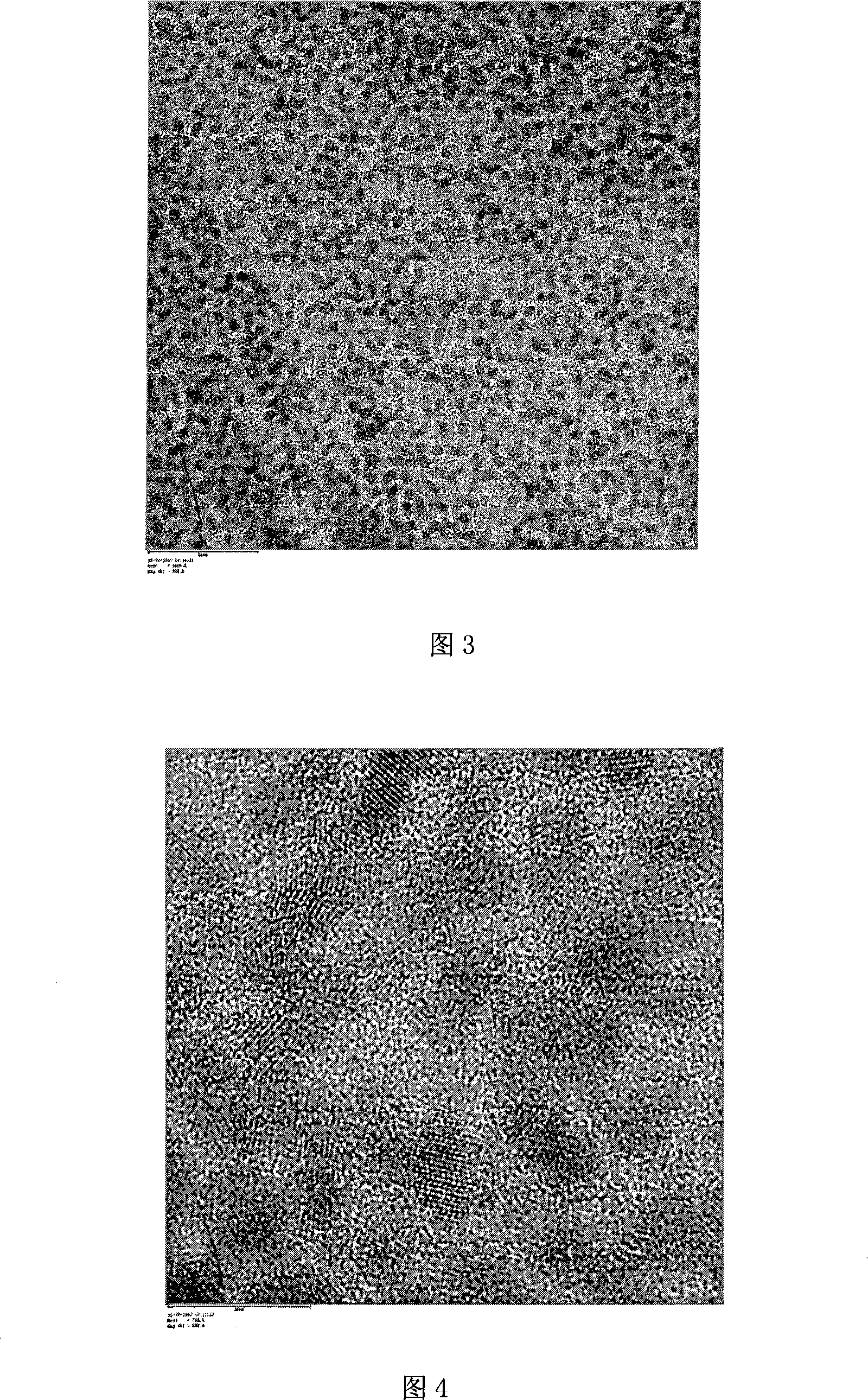

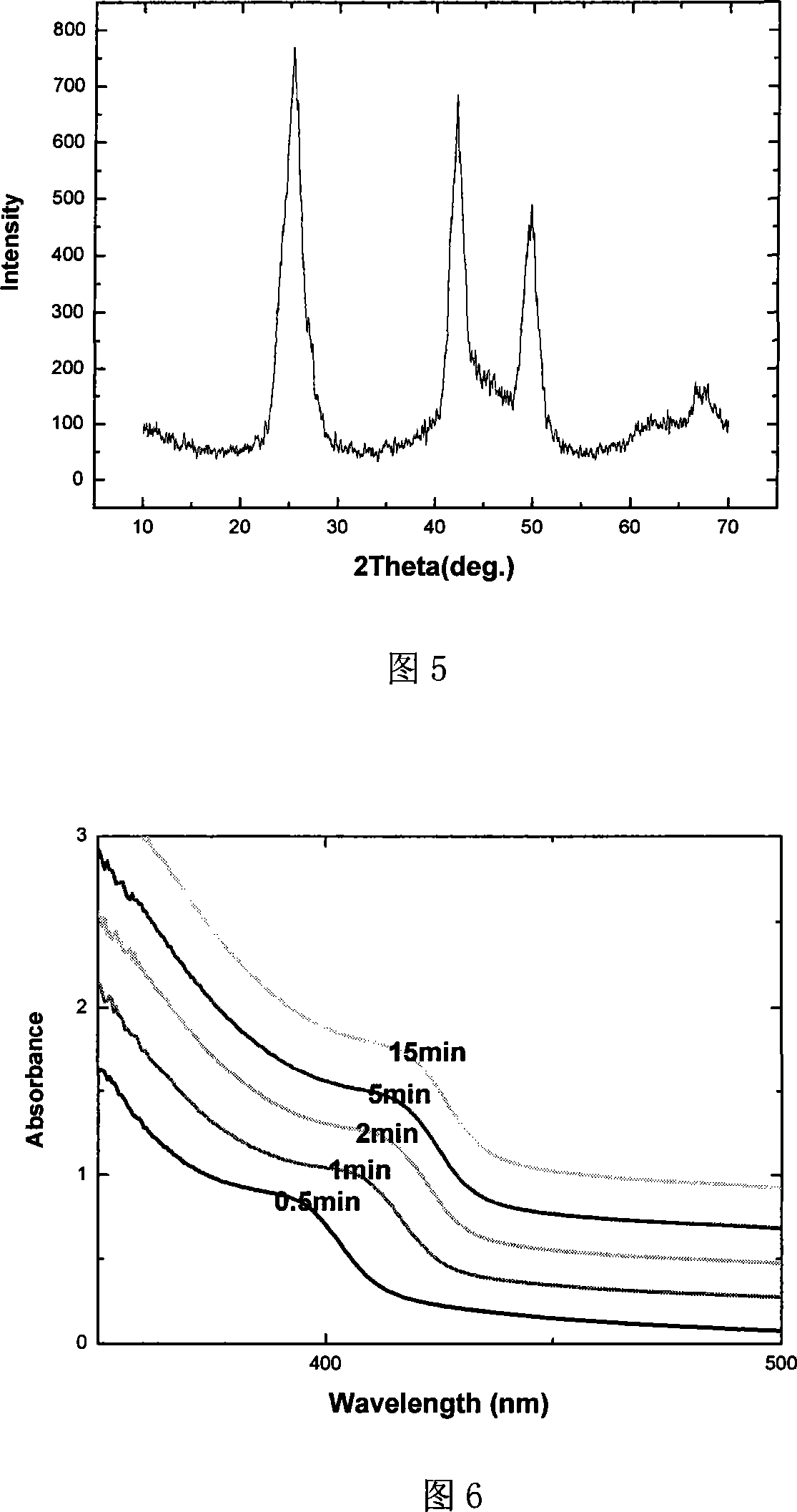

[0038] Preparation of cadmium solution and preparation of quantum dots: 1.000 g of cadmium oleate, 2 ml of oleic acid, 2 ml of dodecyldimethylamine and 8 ml of oleoyl morpholine were mixed, heated to 150° C., and vacuum dehydrated for 0.5 hours. After dehydration, fill with Ar gas protection and heat to 250°C, add Se precursor solution, lower the temperature to about 220-230°C, keep warm at 230±5°C for 1min to 10min (the time is determined according to the size of the product requi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com