Patents

Literature

49results about How to "Moderate stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Non-dairy cream of mixed milk fat and preparation method thereof

The invention designs non-dairy cream of mixed milk fat. The non-dairy cream is characterized by comprising the components in percentage by weight: 8-18% of vegetable fat, 0.05-0.5% of anhydrosorbitan monostearate, 0.02-0.5% of lecithin, 0.02-1% of lactic monoglycerate, 0.02-0.5% of sodium stearyl lactate, 0.05-1% of monoglycerin fatty acid ester and diglycerin fatty acid ester, 0.05-0.8% of sucrose fatty acid ester, 0.02-0.5% of polyglycerol ester, 0.01-1.5% of carrageenan, 0.05-0.8% of microcrystalline cellulose, 0.05-1% of modified cellulose, 0.1-1.5% of sodium caseinate, 0.02-0.2% of potassium dihydrogen phosphate, 2-6% of sugar, 2-12% of corn syrup, 8-18% of milk fat dairy products and 20-60% of water. The non-dairy cream provided by the invention has the advantages that the non-dairy cream is convenient to operate without cream and non-dairy cream which are mixed and whipped topped; the non-dairy cream is more convenient to condition and is not affected by original flavor of the non-dairy cream; the whipped topping rate of the product reaches over 3.6 which is greater than that of existing similar products. The non-dairy cream is more economic and applicable for client.

Owner:SHANGHAI HI ROAD FOOD TECHNOLOGY CO LTD

Selenium precursor fluid and method for preparing cadmium selenide or zinc selenide quantum dots by using the same

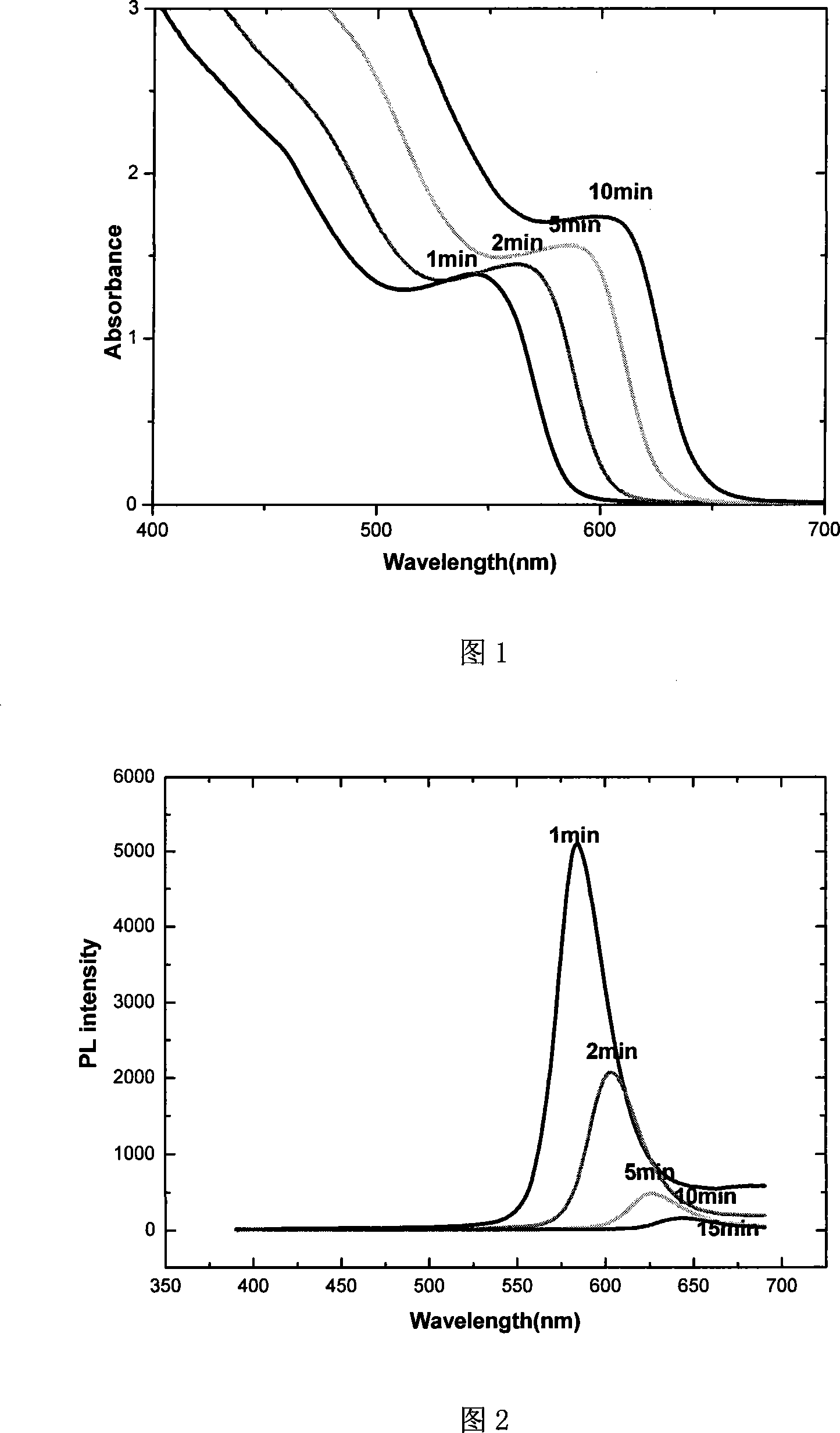

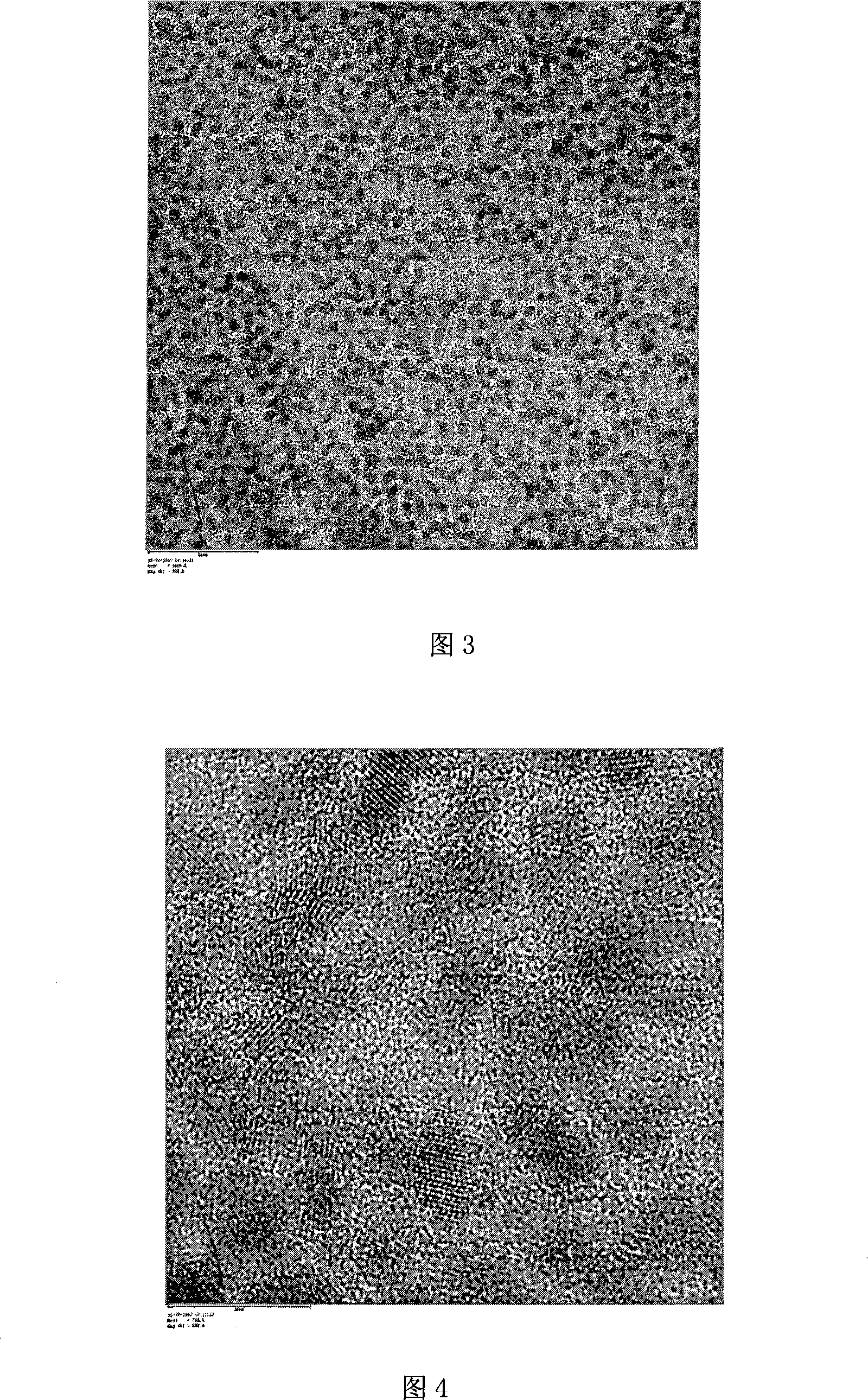

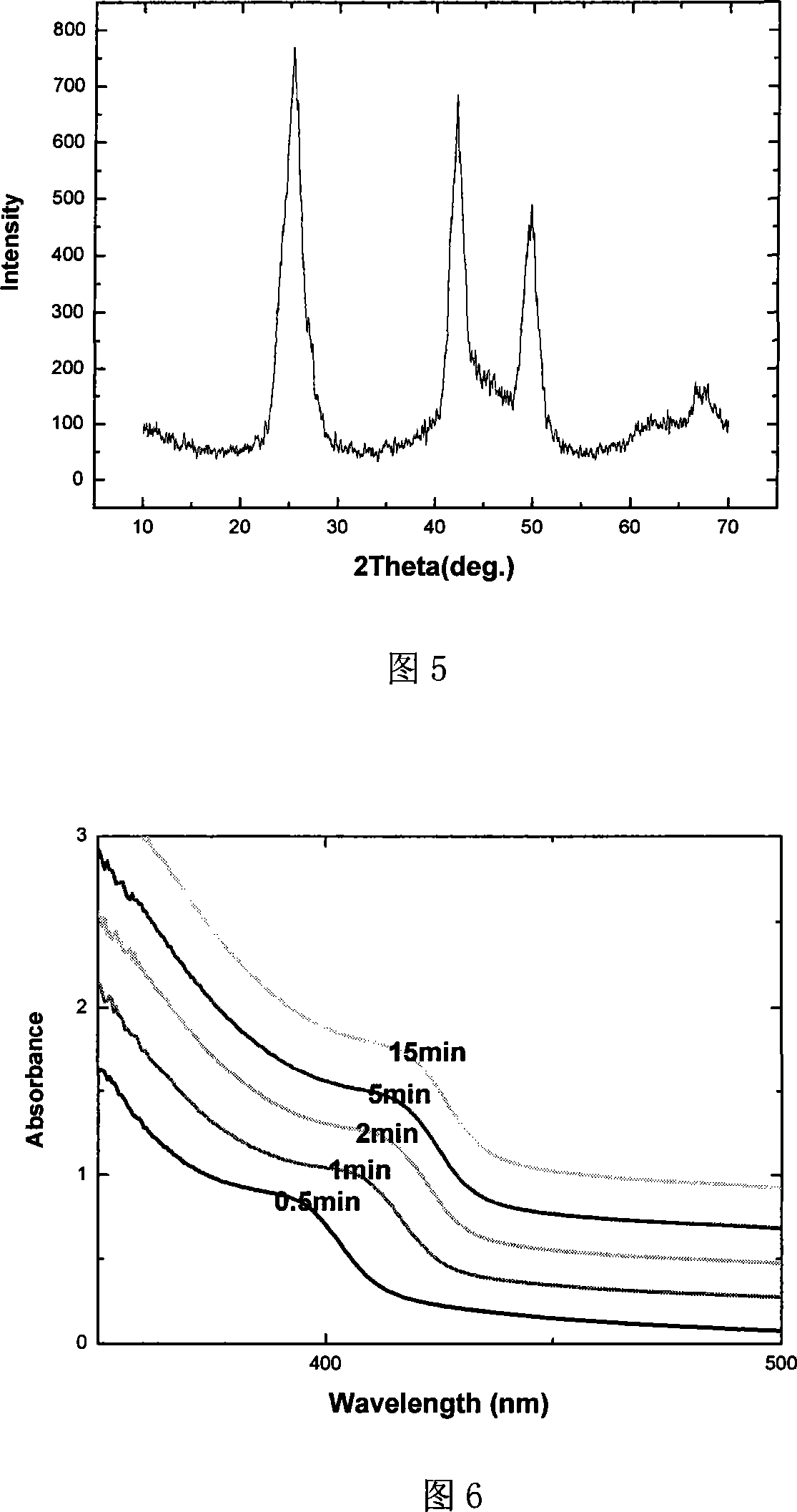

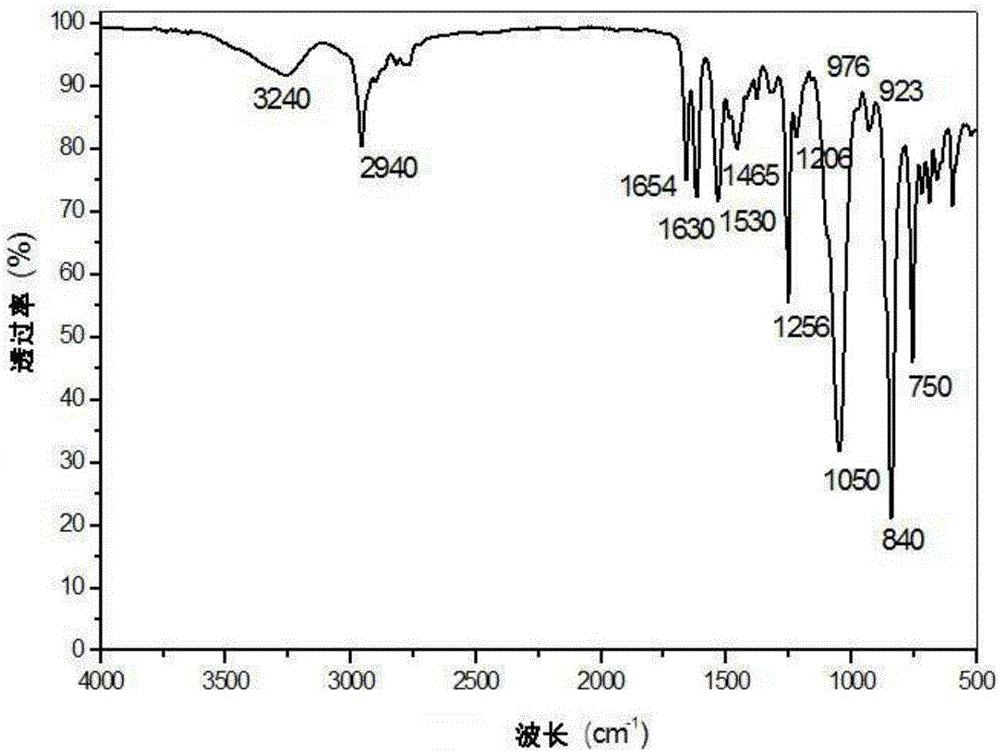

InactiveCN101186825ANarrow size distributionGood monodispersityLuminescent compositionsZinc selenideMorpholine

Provided is a selenium precursor liquid which is achieved by the preparation of heating and dissolving the elemental selenium in oleoyl morpholine under the protection of inert gas. The process for the preparation of cadmium selenide or zinc selenide quantum dots with the selenium precursor liquid is to generate pyrolytic reaction by stirring and mixing the selenium precursor liquid and fatty acid cadmium or fatty acid zincum precursor liquid under the protection of inert gas at a temperature of 150 DEG C to 330 DEG C, and the last is to separate and purify the mixture with low carbon alcohols. The dissolving capacity of the oleoyl morpholine for the elemental selenium is strong, the compatibility of the oleoyl morpholine with other green common solvents is perfect, which can increase the volume productivity of selenide nanocrystalline, thereby achieving quantum dots with relatively narrower size and higher quality.

Owner:HEFEI UNIV OF TECH

Energy-saving, environment-friendly and thermal-insulating material

InactiveCN104710190ASatisfactory melt flow rateHigh flame retardant efficiencyCeramicwareFiberCross-link

The invention discloses an energy-saving, environment-friendly and thermal-insulating material which comprises the following raw materials in parts by weight: 20-28 parts of brominated polystyrene, 5-11 parts of a plant cement foaming agent, 8-16 parts of a cross-linking agent, 40-50 parts of glass fibers, 21-28 parts of mineral slag, 13-21 parts of epoxy resin and 33-41 parts of water. During preparation, the glass fibers are ground, the ground glass fibers and the mineral slag are added into a gravity-free mixing and stirring machine, and a mixture A is obtained; brominated polystyrene and the plant cement foaming agent are put into the stirring machine for performing stirring, the water is added, and a mixture B is obtained; the mixture A is added into the mixture B, and stirring is performed; the cross-linking agent and the epoxy resin are added, and a mixture C is obtained; the mixture C is injected into a mould, and limiting extrusion and curing are performed to obtain the energy-saving, environment-friendly and thermal-insulating material. The energy-saving, environment-friendly and thermal-insulating material is fire-resistant, flame-retardant, high in thermal insulation performance and stable in quality; all adopted raw materials are nontoxic and harmless, so that the material is safe and environment-friendly; moreover, the raw materials are low in price and easily available, so that the material is suitable for floor heating projects and roof insulation projects.

Owner:高彬

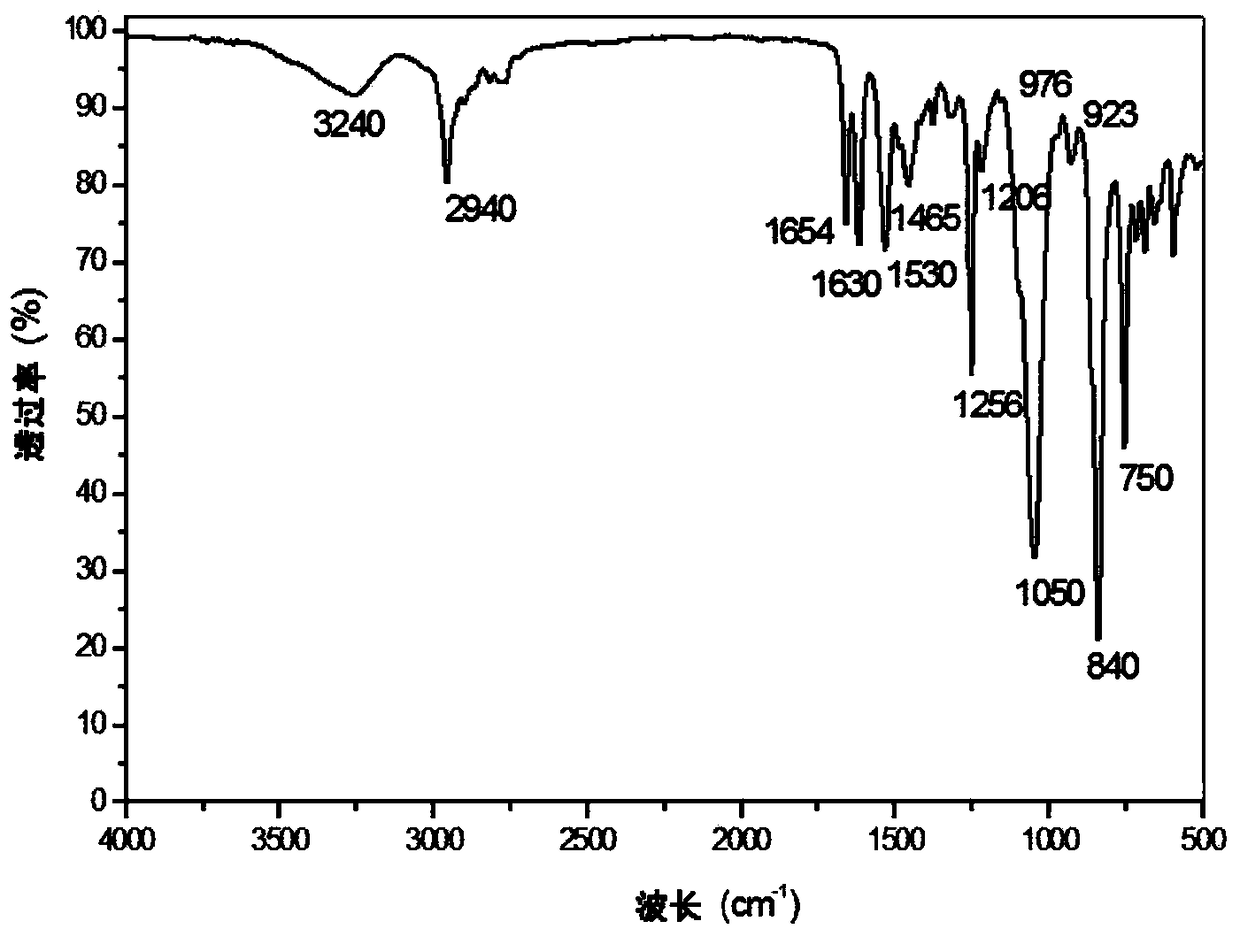

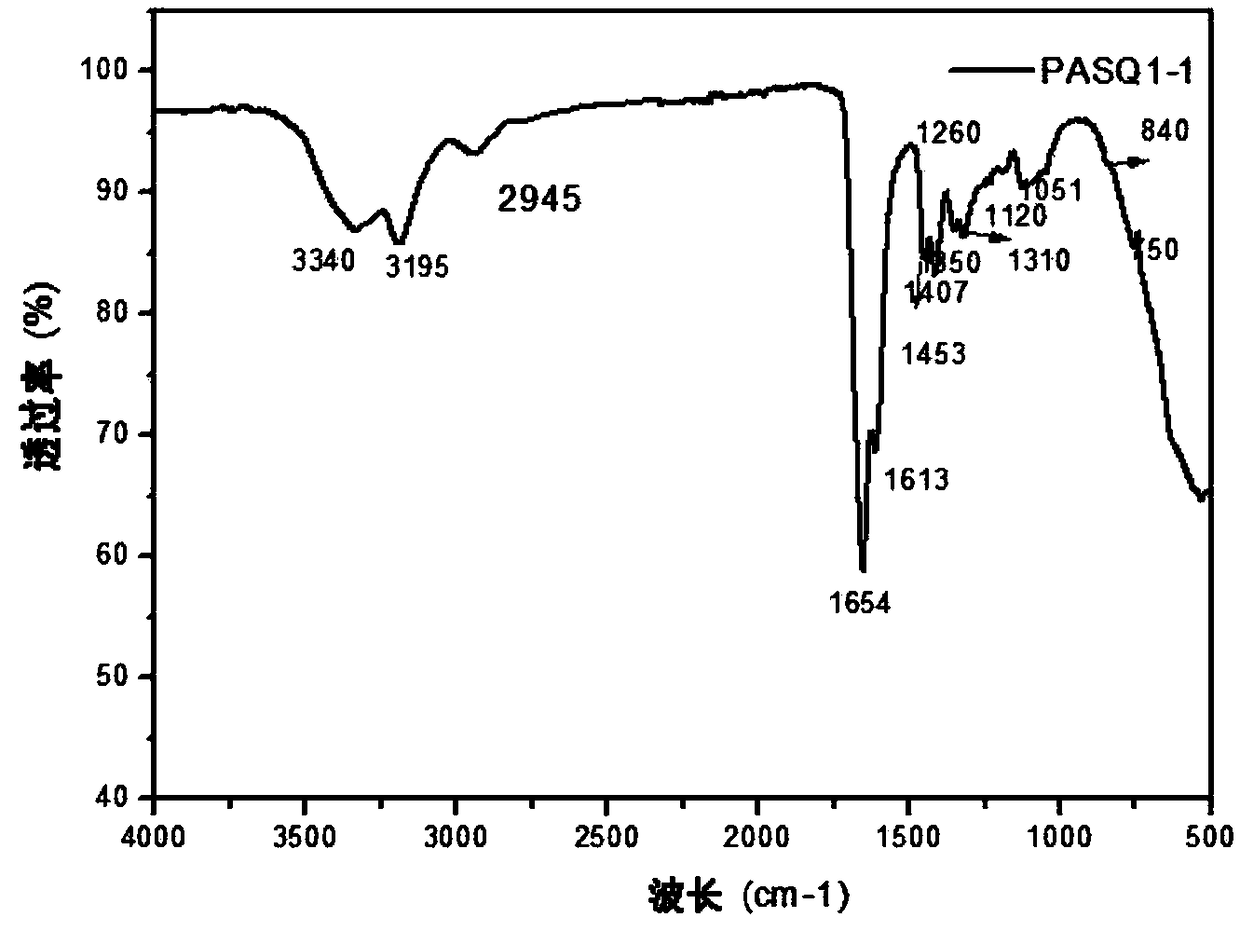

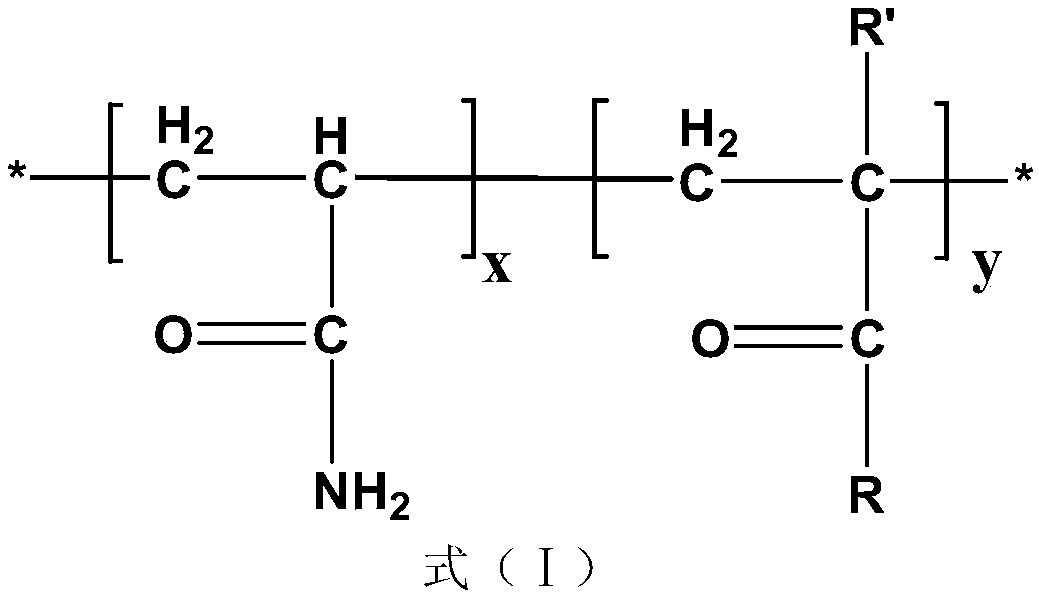

Organic silicone modified amphiphilic polymer type heavy oil viscosity reducer easy to demulsify and dewater and preparation method thereof

ActiveCN106632839AReduce surface tensionHigh temperature resistantDrilling compositionPolymer scienceFiltration

The invention relates to an organic silicone modified amphiphilic polymer type heavy oil viscosity reducer easy to demulsify and dewater and a preparation method thereof. The preparation method for the viscosity reducer comprises the following steps: uniformly mixing and stirring acrylamide, organic silicone quaternary ammonium salt containing double bond and solvent, thereby acquiring a mixed solution; introducing nitrogen, heating to 60-80 DEG C, adding an initiator while stirring, and then reacting for 5-12 hours at 60-80 DEG C, thereby acquiring a reaction solution; cooling the reaction solution and then putting into acetone or ethyl alcohol, performing suction filtration, soaking, washing and drying, thereby acquiring the heavy oil viscosity reducer. The preparation method provided by the invention is simple in operation and low in cost; the prepared viscosity reducer has better heat resistance, salt tolerance and viscosity reducing effects in lower concentration and is easy to demulsify and dewater; the later water treatment difficulty can be reduced; the viscosity reducer need not be compounded with the other auxiliaries, has excellent overall performance and is green and environment-friendly.

Owner:SHANDONG UNIV

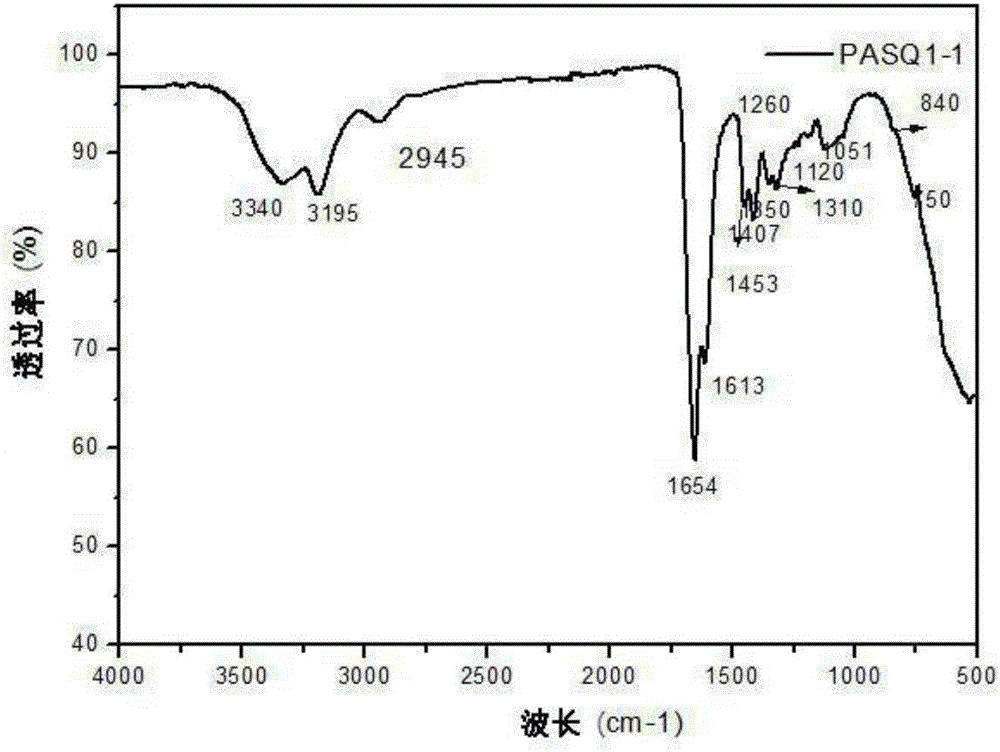

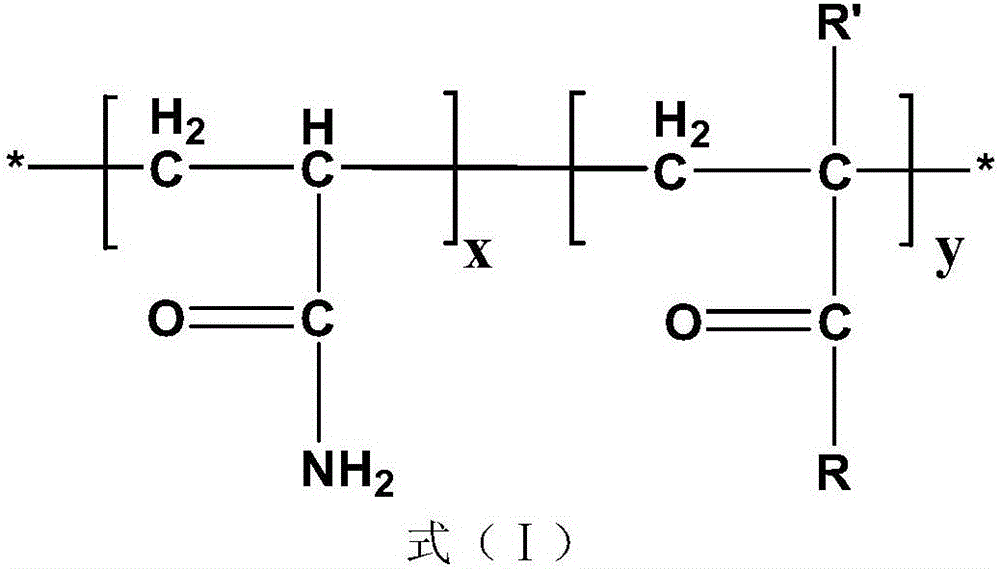

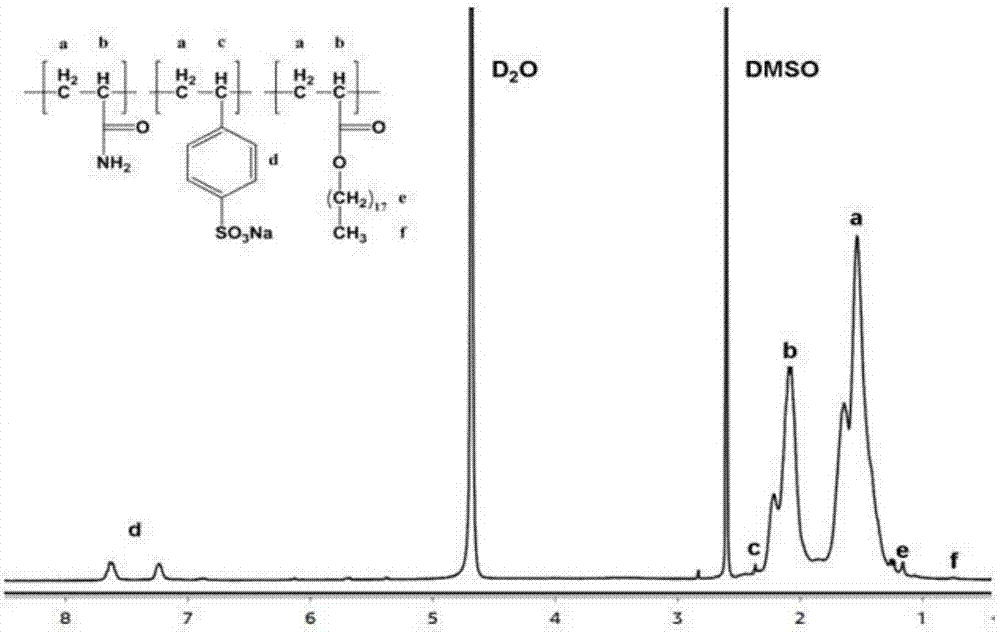

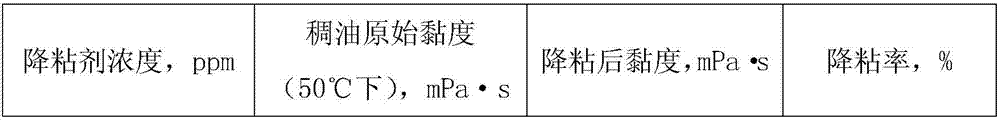

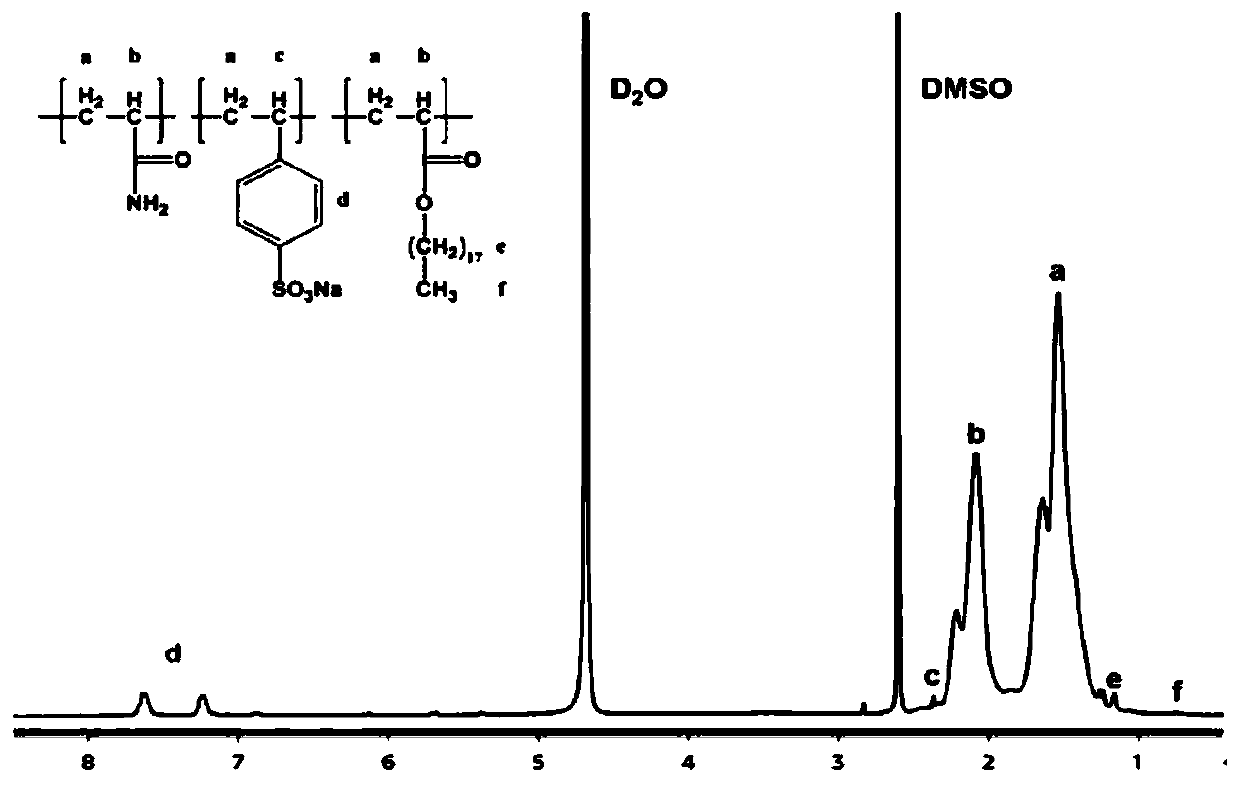

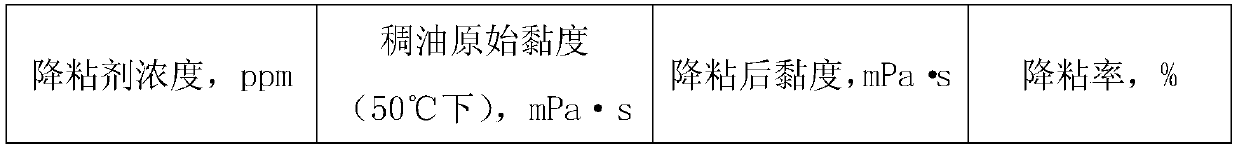

Self-demulsification heavy oil viscosity reducer as well as preparation method and application thereof

ActiveCN107955592AImprove surface activityHigh molecular weightFluid removalDrilling compositionOil viscosityRaw material

The invention relates to a self-demulsification heavy oil viscosity reducer as well as a preparation method and application thereof. The preparation method is characterized in that the self-demulsification heavy oil viscosity reducer is prepared by taking acrylamide, sodium p-styrenesulfonate and octadecyl acrylate as main raw materials; the selected raw materials have low cost and can be preparedinto the self-demulsification heavy oil viscosity reducer by adopting a simple traditional preparation process; meanwhile, an obtained product has high yield and has great advantages in a productionlink of a product; besides, the self-demulsification heavy oil viscosity reducer disclosed by the invention has the advantages of excellent viscosity reduction capability, good temperature and salt resisting effects, more outstanding viscosity reduction effect of extra-heavy oil and self-demulsification performance; integration of viscosity reduction and demulsification can be realized, and efficient oil extraction is realized.

Owner:SHANDONG UNIV

Compound comprising plla and pdla

InactiveUS20140235777A1Easy to transformImprove preferencePlastic/resin/waxes insulatorsInjection mouldingPoly l lactic acid

The present invention relates to a composition comprising a poly-D-lactic acid (PDLA) polymer and a poly-L-lactic acid (PLLA) polymer. The present invention also relates to a method for the production of a moulded part comprising the steps of heating a mould, and supplying to the mould a composition comprising a poly-D-lactic acid (PDLA) polymer and a poly-L-lactic acid (PDLA) polymer. The present invention relates to a composition comprising a poly-D-lactic acid (PDLA) polymer and a poly-L-lactic acid (PLLA) polymer for use in injection-moulding, thermoforming and / or film blowing. The present invention also relates to a composition that can be obtained by heating a composition comprising a poly-D- lactic acid (PDLA) polymer and a poly-L-lactic acid (PDLA) polymer.

Owner:PURAC BIOCHEM

Siloxane quaternary ammonium salt modified amphiphilic polymer ultra-heavy oil viscosity reducer and preparation method and application thereof

ActiveCN107880213AThe synthesis process is simpleEasy to controlDrilling compositionEnvironmental resistanceSalt resistance

The invention provides a siloxane quaternary ammonium salt modified amphiphilic polymer ultra-heavy oil viscosity reducer and a preparation method and an application thereof. Firstly, two kinds of double bond-containing siloxane-based quaternary ammonium salt monomers with different structural features are synthesized, and the viscosity reducer is obtained through radical solution polymerization of the double bond-containing siloxane-based quaternary ammonium salt monomers with cationic monomers and acrylamide respectively. The viscosity reducer is used for ultra-heavy oil and has good viscosity reducing effects, temperature resistance and salt resistance, excellent viscosity reducing effects and the like for high-mineralization ultra-heavy oil. The ultra-heavy oil is easy to be demulsified and dehydrated after being subjected to emulsification and viscosity reduction treatment. The synthetic process of the method is simple and easy to control, the obtained viscosity reducer can be used alone and does not need to be compounded and used together with other additives, and the viscosity reducer is excellent in comprehensive performance, green and environmentally friendly.

Owner:SHANDONG UNIV

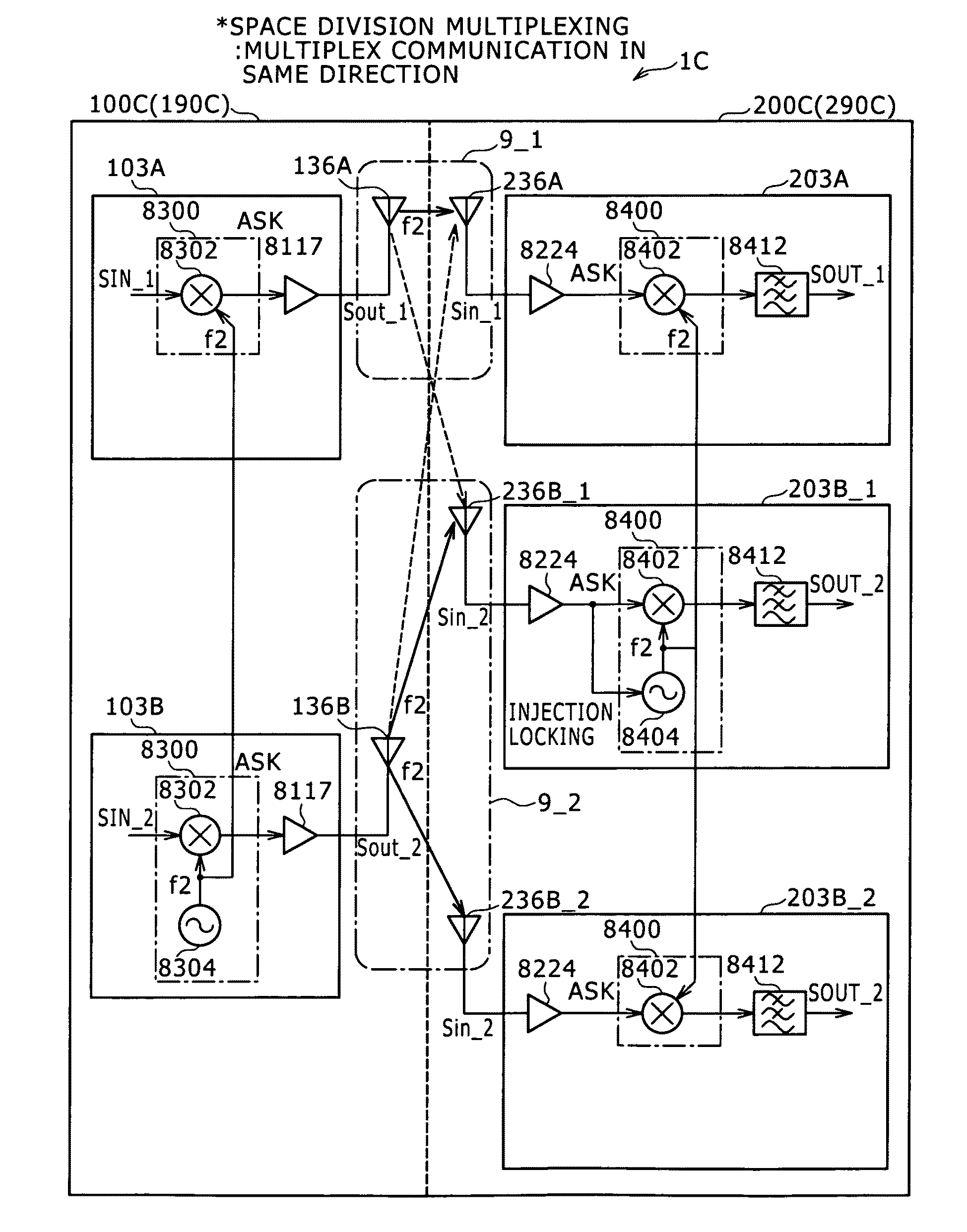

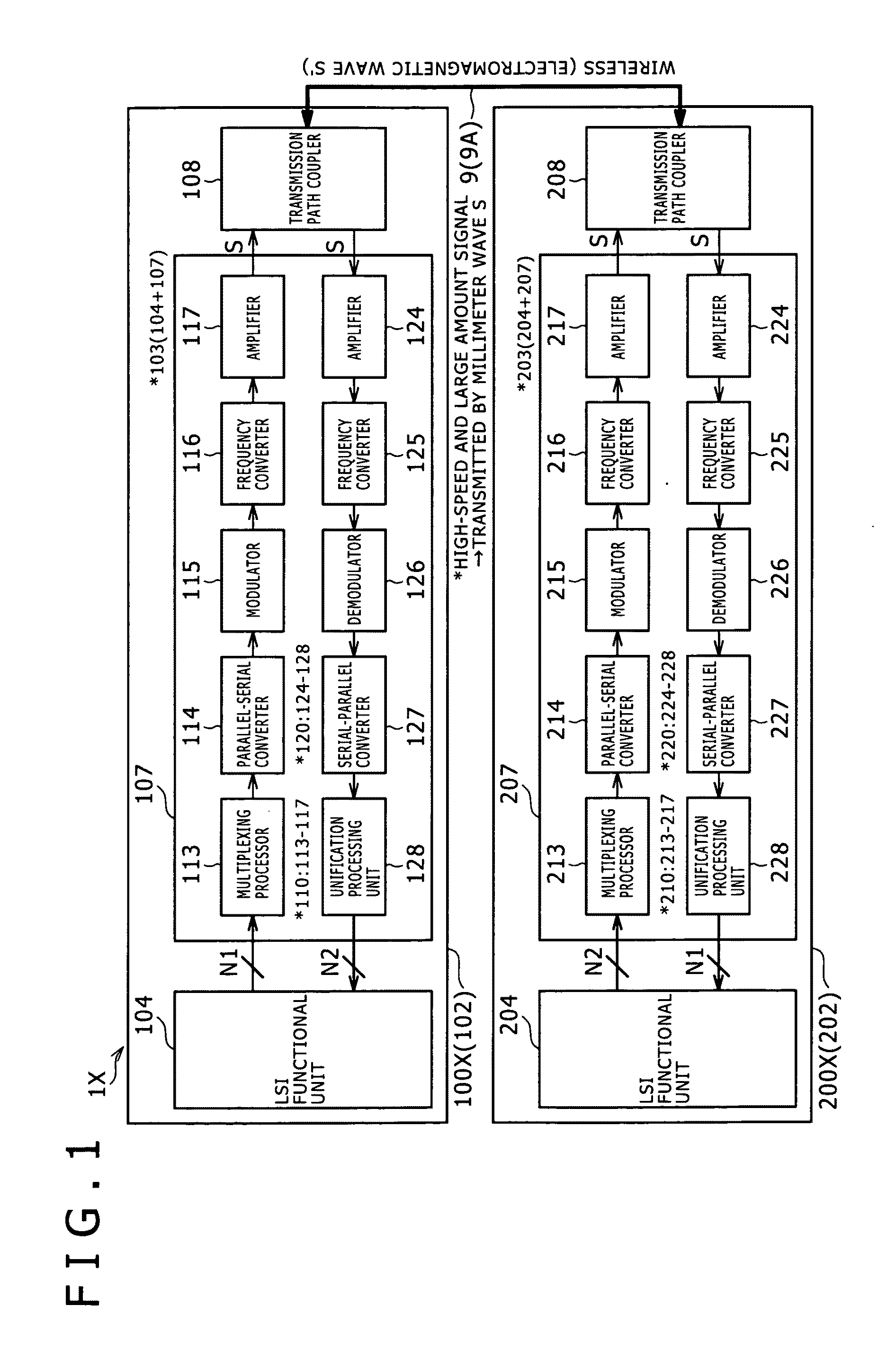

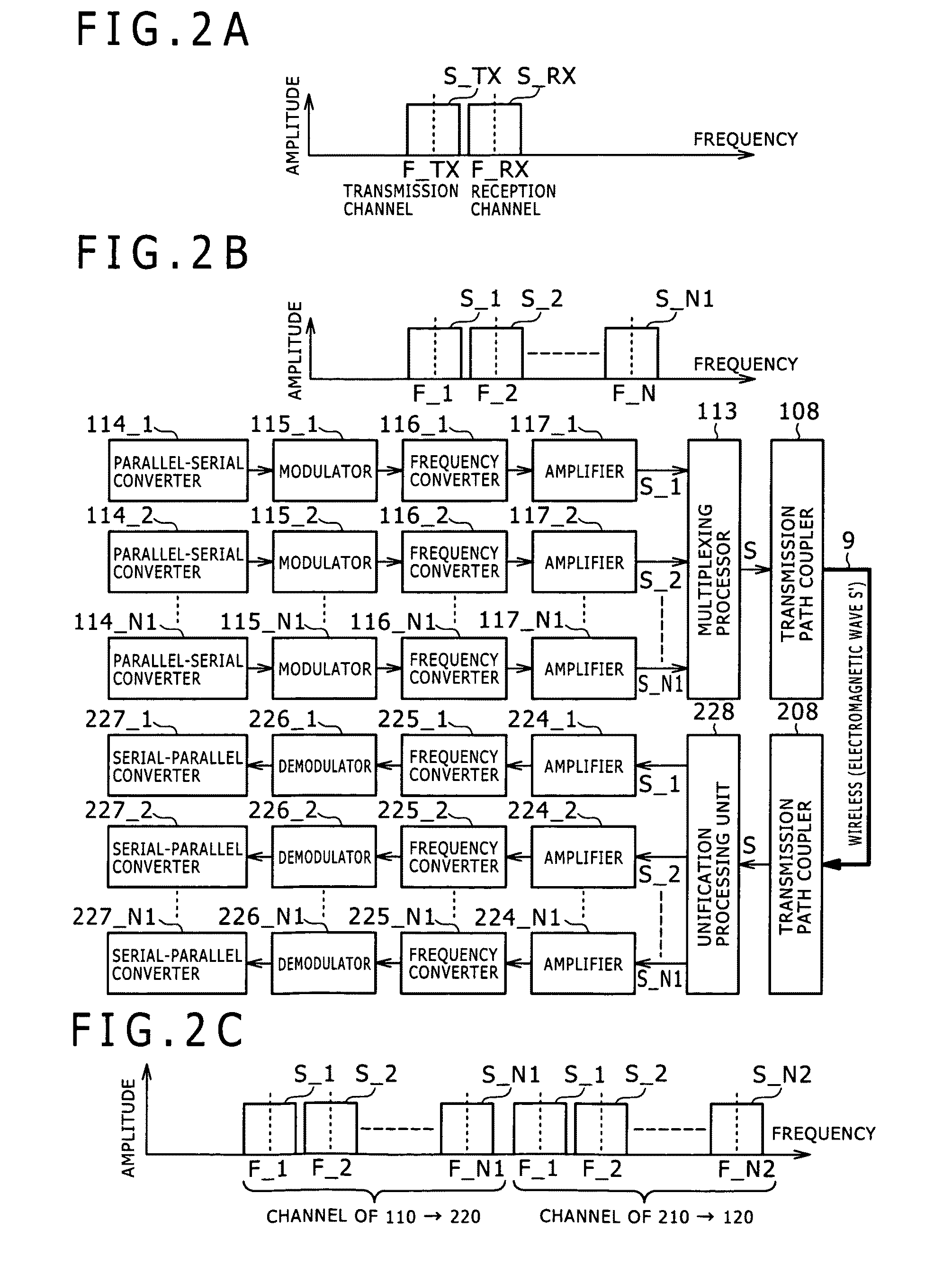

Wireless communication device, wireless transmission system and wireless transmission method

ActiveUS8995935B2Reduce circuit sizeTransmitting power requiredEnergy efficient ICTMultiple modulation transmitter/receiver arrangementsWireless transmissionCommunication unit

Disclosed herein is a wireless communication device, including: a plurality of communication units for transmission adapted to modulate and transmit a transmission subject signal; the communication units for transmission including a communication unit or units for transmission which adopt a method which modulates the amplitude and a communication unit or units for transmission which adopt a modulation method which modulates at least the phase or the frequency and requires transmission power lower than that of the method which modulates the amplitude.

Owner:SONY CORP

A kind of organosilicon modified amphiphilic polymer type heavy oil viscosity reducer which is easy to demulsification and dehydration and preparation method thereof

ActiveCN106632839BReduce surface tensionHigh temperature resistantDrilling compositionPolymer scienceFiltration

The invention relates to an organic silicone modified amphiphilic polymer type heavy oil viscosity reducer easy to demulsify and dewater and a preparation method thereof. The preparation method for the viscosity reducer comprises the following steps: uniformly mixing and stirring acrylamide, organic silicone quaternary ammonium salt containing double bond and solvent, thereby acquiring a mixed solution; introducing nitrogen, heating to 60-80 DEG C, adding an initiator while stirring, and then reacting for 5-12 hours at 60-80 DEG C, thereby acquiring a reaction solution; cooling the reaction solution and then putting into acetone or ethyl alcohol, performing suction filtration, soaking, washing and drying, thereby acquiring the heavy oil viscosity reducer. The preparation method provided by the invention is simple in operation and low in cost; the prepared viscosity reducer has better heat resistance, salt tolerance and viscosity reducing effects in lower concentration and is easy to demulsify and dewater; the later water treatment difficulty can be reduced; the viscosity reducer need not be compounded with the other auxiliaries, has excellent overall performance and is green and environment-friendly.

Owner:SHANDONG UNIV

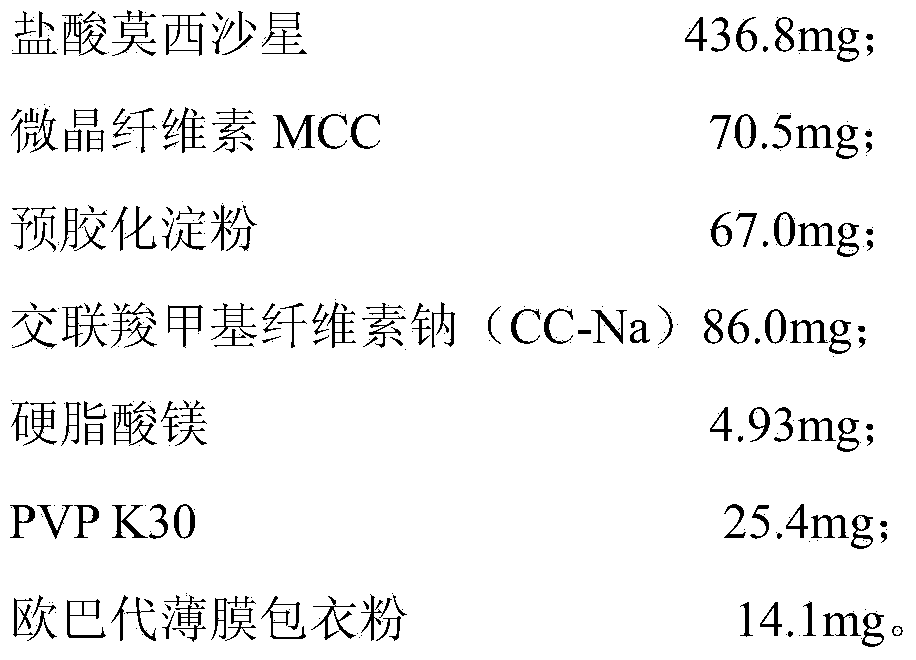

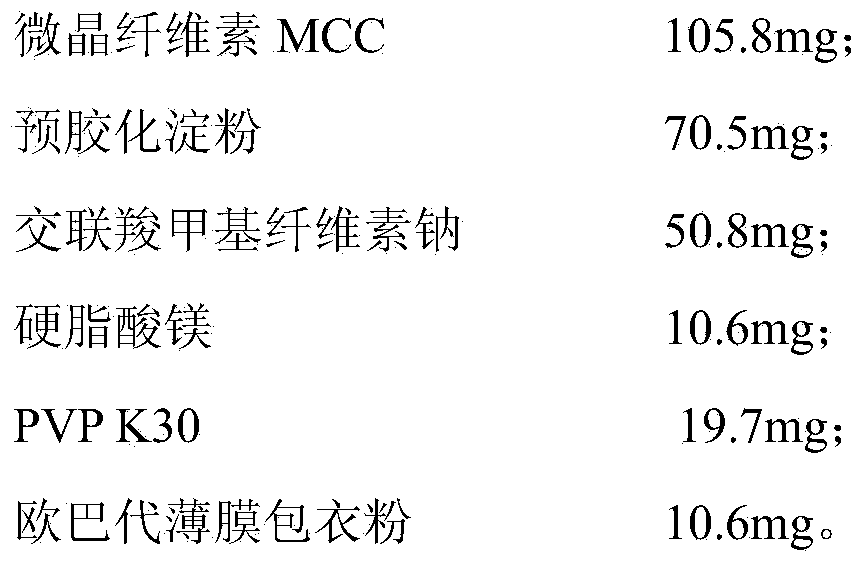

Moxifloxacin hydrochloride tablet and preparation method thereof

ActiveCN103655507AGood appearance and stabilityThe preparation process is simple and easyAntibacterial agentsOrganic active ingredientsFilm coatingAdhesive

The invention relates to the field of pharmacy technologies and in particular relates to a moxifloxacin hydrochloride tablet and a preparation method thereof. The moxifloxacin hydrochloride tablet is prepared from the following raw materials in parts by weight: 60-64 parts of moxifloxacin hydrochloride, 19-26 parts of filler, 7.0-12.5 parts of disintegrating agent, 0.6-1.6 parts of flow aid, 2.5-3.7 parts of adhesive and 1.4-2.6 parts of opadry film coating powder. The preparation method of the moxifloxacin hydrochloride tablet is simple and feasible. Due to the proportional composition of the components of the moxifloxacin hydrochloride tablet and the process, the problem of disintegrating time limit is solved; due to the adoption of the opadry film coating powder, the moxifloxacin hydrochloride tablet is attractive in appearance and the stability of the tablet is ensured; the moxifloxacin hydrochloride tablet is appropriate in hardness, disintegration property, dissolvability and stability; in addition, the auxiliary material used for the moxifloxacin hydrochloride tablet is low in cost, safe and reliable; industrialization and clinical use are facilitated.

Owner:山东淄博新达制药有限公司

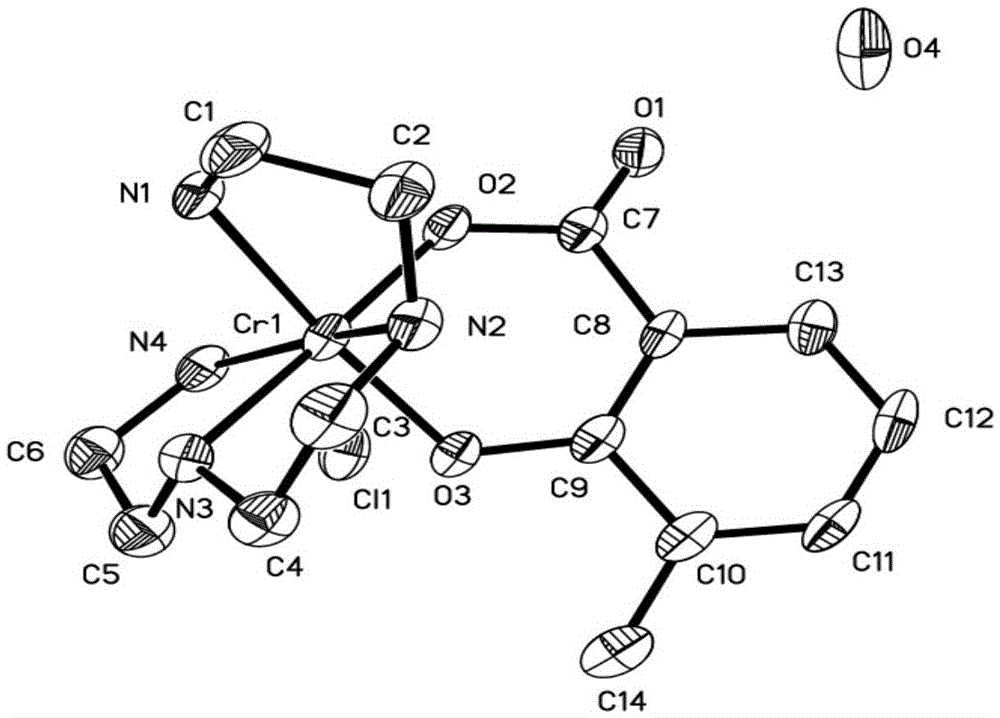

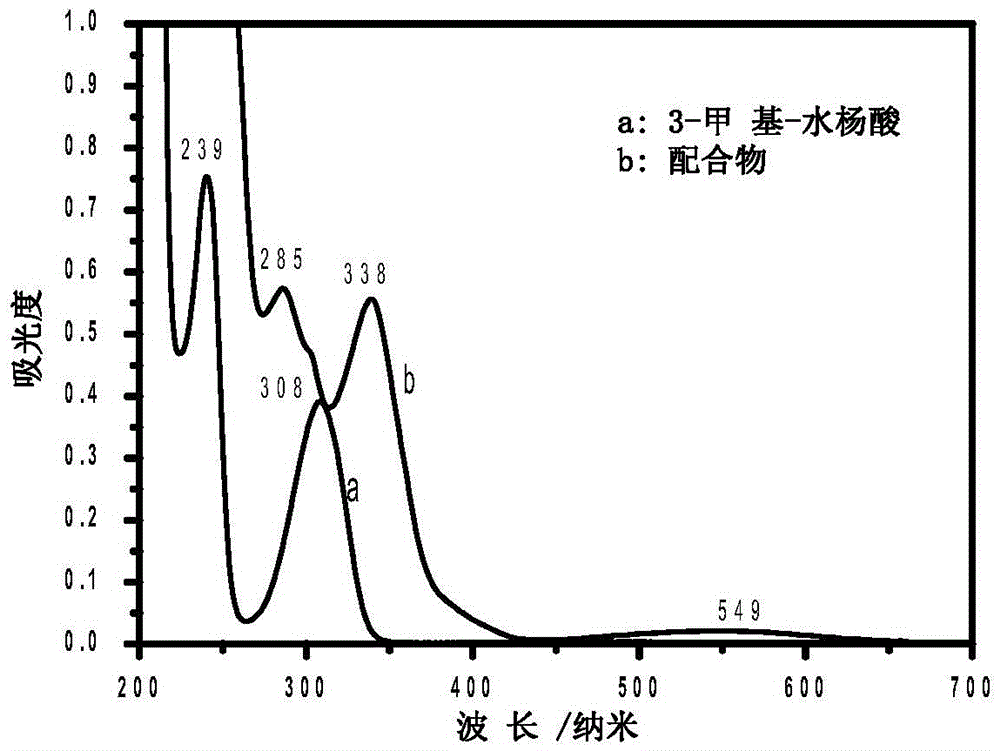

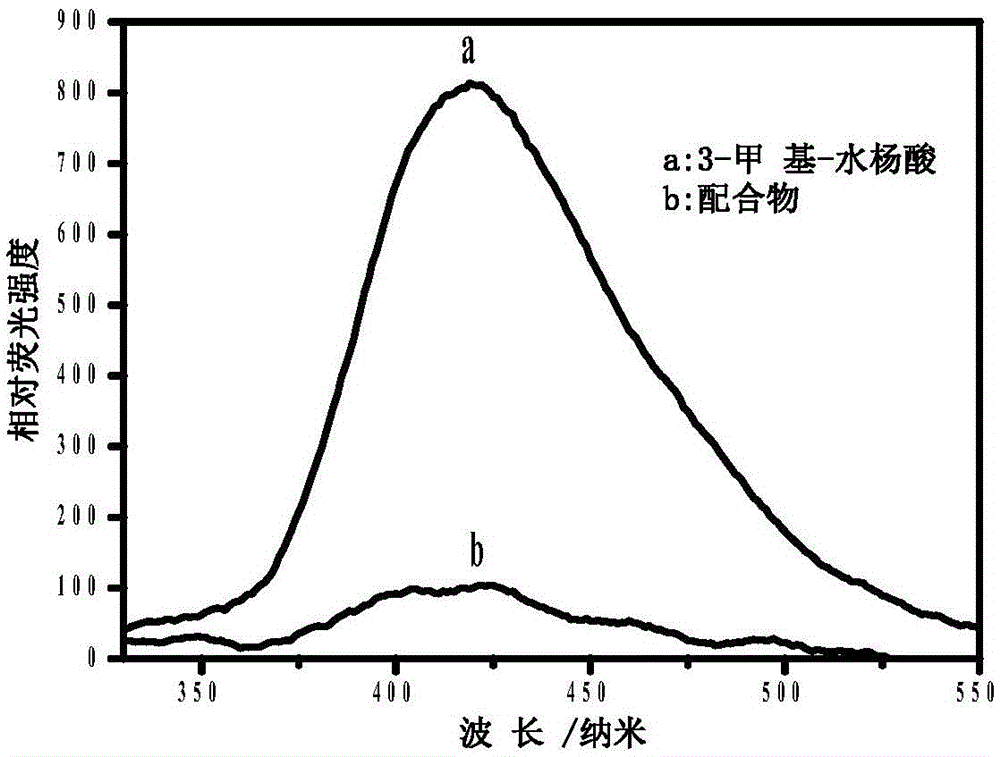

Chromium (III) complex as well as preparation method and application thereof

InactiveCN105601670AGood water solubilityModerate stabilityMetabolism disorderOrganic chemistry methodsRefluxOrganic solvent

The invention provides a chromium (III) complex as well as a preparation method and application thereof. According to the chromium (III) complex, the molecular formula is CrC14H26N4O4Cl, the molecular weight is 402, the crystal structure belongs to a triclinic crystal system, the spatial point group is P-1, a is equal to 7.8880(6), b is equal to 9.8380(7), c is equal to 14.4490(12) angstroms, alpha is equal to 70.4550(10), beta is equal to 85.729(2), gamma is equal to 82.0880(10) degrees, V is equal to 1046.12(14) cubic angstroms, and Z is equal to 2. The preparation method comprises the steps of dissolving chromium (III) and 3-methyl-salicylic acid by virtue of an organic solvent, feeding a small amount of zinc granules, carrying out heating reflux, then dropwise adding triethylene tetramine, continuing to carry out reflux for a period of time, stopping reaction, cooling, filtering, standing obtained filtrate, and naturally volatilizing at the normal temperature, so as to obtain purple red crystals. The chromium (III) complex can be applied to the preparation of sugar-reducing medicines.

Owner:SHANXI UNIV

Polyphenol-containing Kefir fermented whey beverage and manufacturing method thereof

InactiveCN107156325AFull of nutritionLow fermentation temperatureWhey manufactureFood additiveFruit juice

A polyphenol-containing Kefir fermented whey beverage belongs to the technical field of food processing. The polyphenol-containing Kefir fermented whey beverage is prepared from the following steps of 1) mixing and dissolving demineralized whey powder in water, and then filtering the mixture; 2) adding merchant concentrated juice into solution obtained in the step 1), adjusting the brix of the mixed liquid to 14 degrees Bx, performing homogenizing, keeping the homogenized liquid at 85 DEG C for 15 min for sterilization, then rapidly cooling down to 28-40 DEG C; 3) inoculating activated Kefir M into the mixed liquid obtained in the step 2) at a weight ratio of 2-8% of the mixed liquid, stirring to mixing the liquid and then fermenting the liquid at a constant temperature of 28-40 DEG C for 5-17 hours, and performing aseptic filling to obtain finished products. The polyphenol-containing Kefir fermented whey beverage is high in content of polyphenol and contains live probiotics without other food additives, and meanwhile, is fresh in taste and rich in nutrition.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

A self-demulsifying heavy oil viscosity reducer and its preparation method and application

ActiveCN107955592BImprove surface activityHigh molecular weightFluid removalDrilling compositionOil viscosityReducing agent

The invention relates to a self-demulsification heavy oil viscosity reducer as well as a preparation method and application thereof. The preparation method is characterized in that the self-demulsification heavy oil viscosity reducer is prepared by taking acrylamide, sodium p-styrenesulfonate and octadecyl acrylate as main raw materials; the selected raw materials have low cost and can be preparedinto the self-demulsification heavy oil viscosity reducer by adopting a simple traditional preparation process; meanwhile, an obtained product has high yield and has great advantages in a productionlink of a product; besides, the self-demulsification heavy oil viscosity reducer disclosed by the invention has the advantages of excellent viscosity reduction capability, good temperature and salt resisting effects, more outstanding viscosity reduction effect of extra-heavy oil and self-demulsification performance; integration of viscosity reduction and demulsification can be realized, and efficient oil extraction is realized.

Owner:SHANDONG UNIV

Efficient composite viscosity reduction agent for viscous oil recovery

InactiveCN108865096AIncreased mining recoveryImprove displacementDrilling compositionAlkylphenolOil production

The invention relates to the technical field of oil production, and particularly relates to an efficient composite viscosity reduction agent suitable for viscous oil reservoir recovery. The compositeviscosity reduction agent is prepared from the following raw materials in percentage by mass: 10 to 15% of sodium lauryl sulfate, 5 to 10% of sodium dodecylbenzene sulfonate, 13 to 15% of alkylphenolethoxylate, 15 to 30% of polyacrylate and the balance of water. The alkylphenol ethoxylate is a condensation compound of alkylphenol and ethylene oxide. The polyacrylate is a segmented copolymer of ethyl acrylate and butyl acrylate, which has a molecular weight of 50 to 300 thousand. The efficient composite viscosity reduction agent disclosed by the invention is high in viscosity reduction rate; the viscous oil viscosity reduction rate can reach 98% in a range of 30 to 70 DEG C; the efficient composite viscosity reduction agent can be widely applied to viscous oil recovery.

Owner:YANTAI ZHIBEN INTPROP OPERATIONS MANAGEMENT CO LTD

Rare-earth ultrastable Y-type molecular sieve and preparation method thereof

ActiveCN103962168AHigh crystallinityGood dispersionCatalytic crackingMolecular sieve catalystsMolecular sieveRare earth

The invention relates to a high-dispersion rare-earth ultrastable Y-type molecular sieve and a preparation method thereof, and in particular to a modified molecular sieve for preparation of a catalytic cracking catalyst and a preparation method thereof. Since the NaY molecular sieve in the invention is pretreated, the physical and chemical properties such as degree of crystallinity, dispersibility and stability of the zeolite NaY can be improved significantly. Compared with the ultrastable molecular sieve with the same rare earth content prepared by a conventional method, the rare-earth ultrastable Y-type molecular sieve prepared by the two exchange and two calcination method disclosed by the invention has the characteristics of low rare earth content, good dispersibility and stability, low coke yield and strong heavy oil conversion ability; and the has the process is simple, low in cost and pollution-free.

Owner:PETROCHINA CO LTD

A rare earth ultra-stable Y-type molecular sieve and its preparation method

ActiveCN103962168BHigh crystallinityGood dispersionCatalytic crackingMolecular sieve catalystsMolecular sievePtru catalyst

The invention relates to a high-dispersion rare-earth ultrastable Y-type molecular sieve and a preparation method thereof, and in particular to a modified molecular sieve for preparation of a catalytic cracking catalyst and a preparation method thereof. Since the NaY molecular sieve in the invention is pretreated, the physical and chemical properties such as degree of crystallinity, dispersibility and stability of the zeolite NaY can be improved significantly. Compared with the ultrastable molecular sieve with the same rare earth content prepared by a conventional method, the rare-earth ultrastable Y-type molecular sieve prepared by the two exchange and two calcination method disclosed by the invention has the characteristics of low rare earth content, good dispersibility and stability, low coke yield and strong heavy oil conversion ability; and the has the process is simple, low in cost and pollution-free.

Owner:PETROCHINA CO LTD

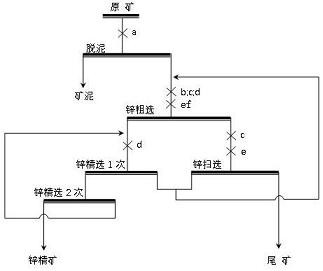

Flotation separation method of high grade lead-sulfur mixed concentrate

The invention relates to a flotation separation method of a high grade lead-sulfur mixed concentrate, and belongs to the technical field of metal mineral processing. The flotation separation method includes the following steps that (1) a high-grade lead-zinc-sulfur raw ore is ground through a ball mill, ethyl xanthogenate, zinc sulfate and second flotation oil are added for mixed flotation of leadand sulfur, and the lead-sulfur concentrate is obtained; (2) an sodium hydroxide, sodium sulfite, sodium thiosulfate, fulvic acid compound inhibitor is added, the size mixing time is greater than orequal to 5 minutes, and the ore pulp condition achieves that ore pulp electric potential is less than or equal to -260 mV(SHE), pH is greater than or equal to 12, and ore pulp dissolved oxygen is lessthan or equal to 4.5 mg / L; and (3) the purposes of flotation and separation of galena and pyrite are achieved through once roughing, twice concentration (concentration twice supplementation and compound inhibitor) and twice scavenging separation and flotation operation. The flotation separation method is low in cost and high in metal recovery rate, pressure of upstream and downstream operation and water treatment operation can be reduced, adaptability to flotation and separation of a high grade lead-sulfur mixed concentrate difficult to separate is strong, the effect is significant, and industrial production requirements can be met.

Owner:YILIANG CHIHONG MINING IND +1

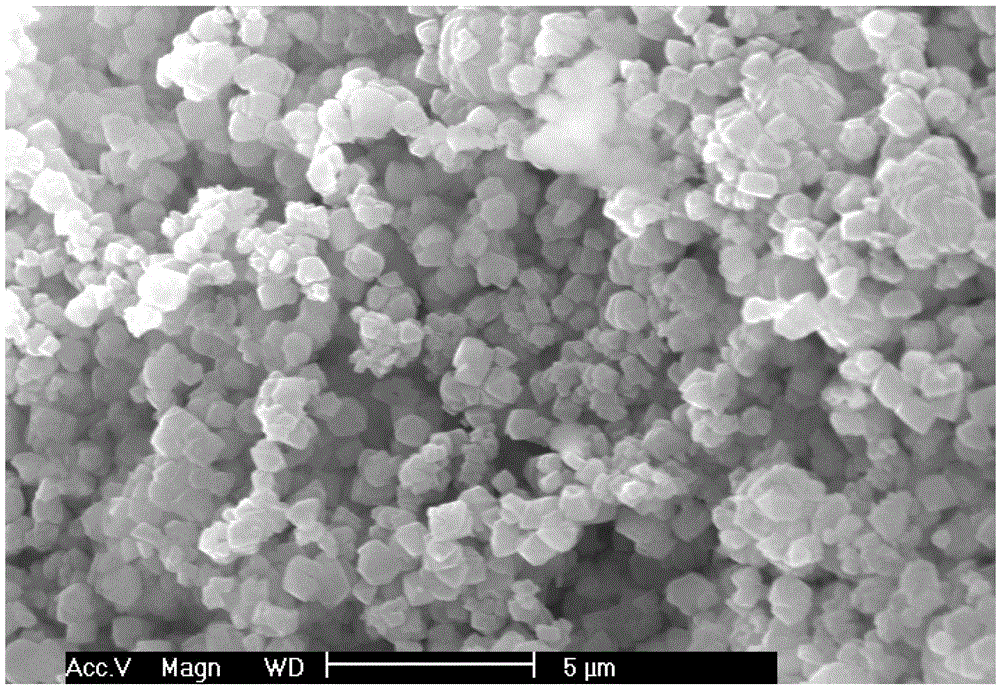

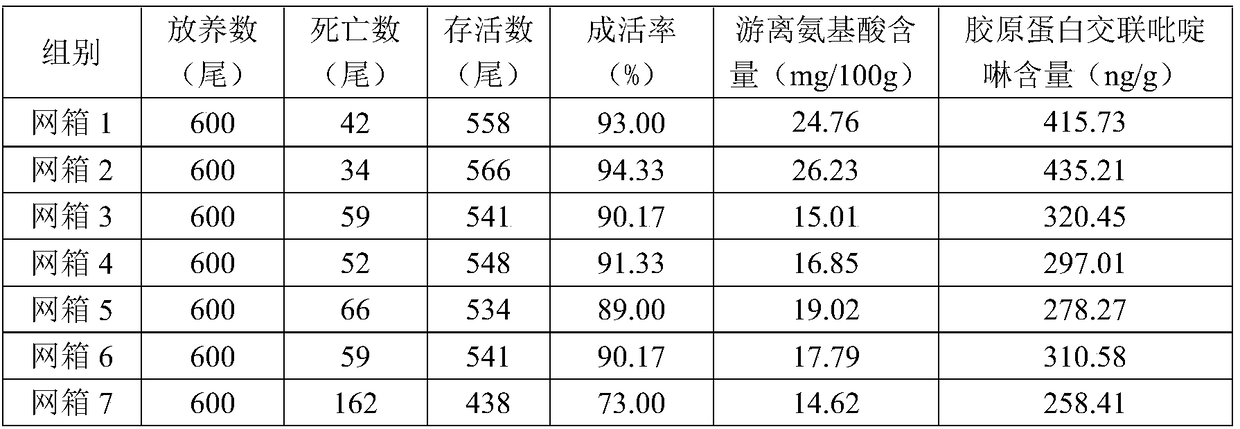

Feed additive capable of improving quality of marine culture fish and preparation method thereof

InactiveCN109362997AModerate stabilityEnhance phagocytic activityAccessory food factorsAnti stressFeed additive

The invention provides a feed additive capable of improving the quality of marine culture fish and a preparation method thereof, and belongs to the technical field of marine culture. The feed additivecomprises an organic chromium complex which contains at least two kinds of amino acid ligands, wherein the at least two kinds of amino acids are selected from methionine, cysteine, alanine, glycine,proline, glutamic acid or histidine. The preparation method comprises the following steps: preparing the organic chromium complex by a microwave heating solid phase synthesis method, and mixing the organic chromium complex with a chitosan oligosaccharide complex to obtain the feed additive, wherein sodium citrate and D-alanine are added in the microwave heating solid phase synthesis reaction. Thefeed additive provided by the invention can participate in carbohydrate metabolism in bodies, improve the immune function and anti-stress ability of animals, and improve the flavor and muscle qualityof fish to be more approximate to wild fish; and the preparation method has low energy consumption and high yield, and the prepared organic chromium complex has moderate stability.

Owner:MARINE FISHERIES RES INST OF ZHEJIANG

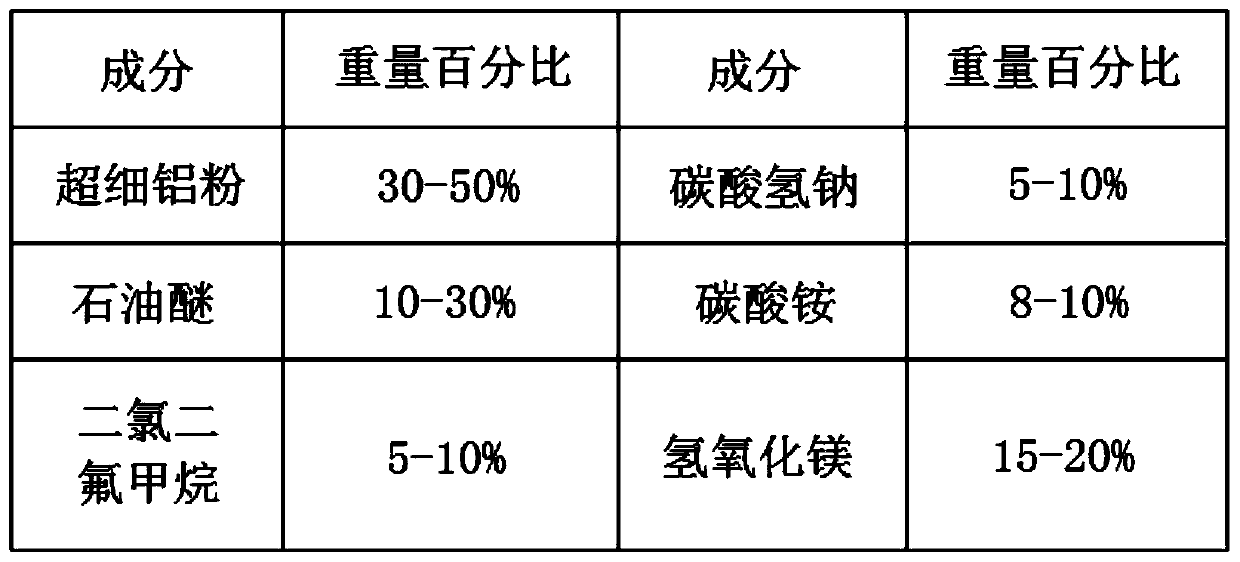

Foaming agent

The invention relates to a foaming agent and belongs to the technical field of chemical paint. The foaming agent is characterized by being prepared from the following raw materials in parts by weight: 1 to 3 parts of ultrafine aluminum powder, 6 to 10 parts of petroleum ether, 2 to 6 parts of dichlorodifluoromethane, 0.5 to 1 part of sodium hydrogen carbonate, 1 to 2 parts of ammonium carbonate, 0.5 to 1 part of ammonium nitrite, 2 to 4 parts of sodium silicate and 2 to 5 parts of magnesium hydroxide. The foaming agent provided by the invention has no corrosion to cement and metal and short degradation time, is easy to recycle and has high fire resistance; pollution to the environment is not generated; the foaming agent can be stored for long time and does not easily go bad; the stability of foam is moderate and the foaming agent is convenient to transport.

Owner:徐勤凤

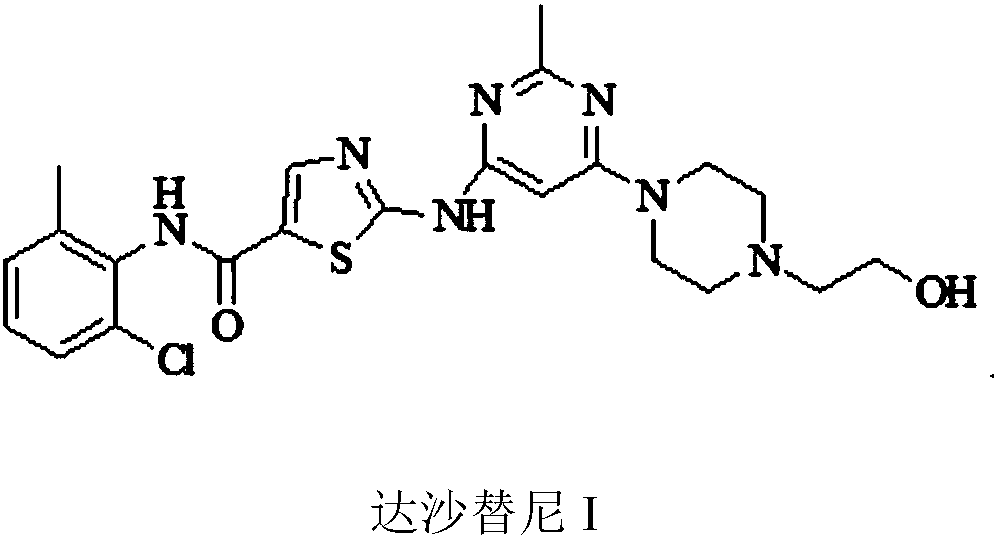

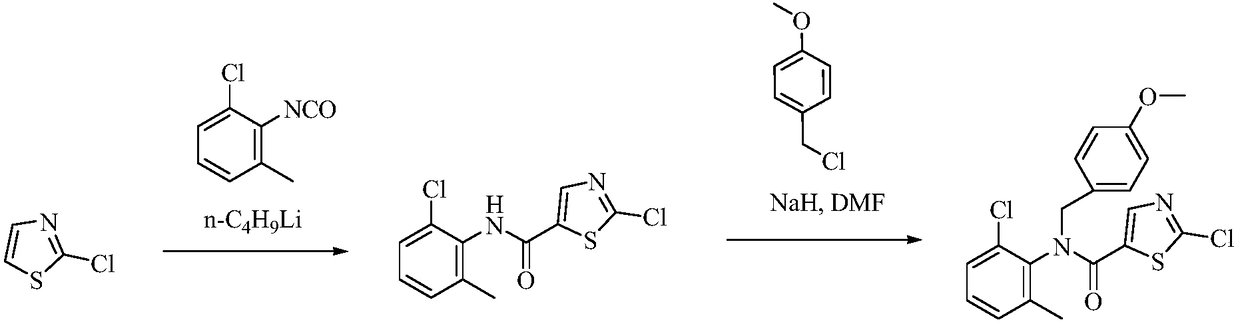

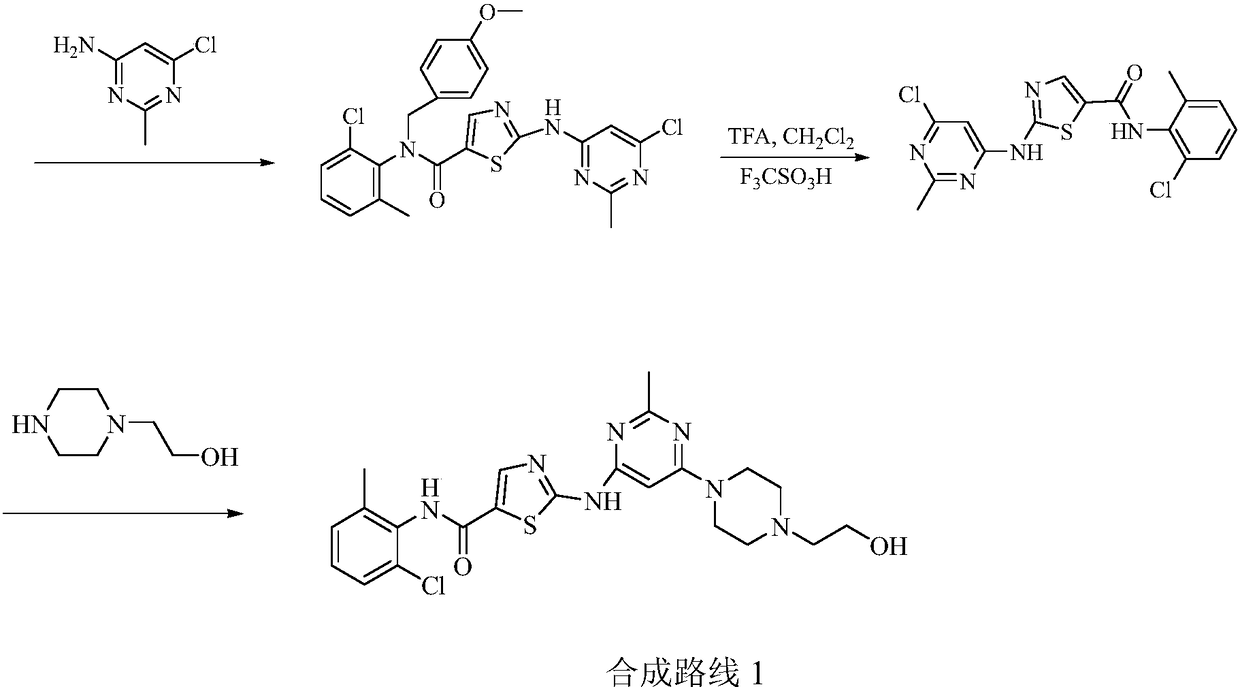

Preparation method of Dasatinib

The invention provides a preparation method of Dasatinib. 2-Bromothiazole-5-formic acid and 2-methyl-4-amino-6-cloro pyridine are adopted as raw materials, a first-time substitution reaction is performed, the raw materials and 4-(2-acetyl oxyl) Ethylpiperazine are subjected to a second-time substitution reaction to prepare 2-[[6-[4-(2-acetyloxy ethyl)-1-piperazinyl]-2-methl-4-pyrimidyl]amino]-5-Febuxostat; then, the product and an acylating chlorination reagent are subjected to an acylating chlorination reaction and subjected to an amidation reaction with 2-cholo-6-methylaniline, and finally ahydrolysis reaction is performed to remove acetyl to prepare dasatinib. The raw materials are cheap and easy to obtain and low in cost; the technological process is simple, operation is safe and easy, technological wastewater generation amount is small, and the method is environmentally friendly; raw materials and intermediate products stability is suitable, the reaction activity and selectivityare high, reaction conditions are easy to obtain, side reactions are few, the manufactured dasatinib contains few impurities, the purity and yield are high, and industrial production of dasatinib is facilitated.

Owner:XINFA PHARMA

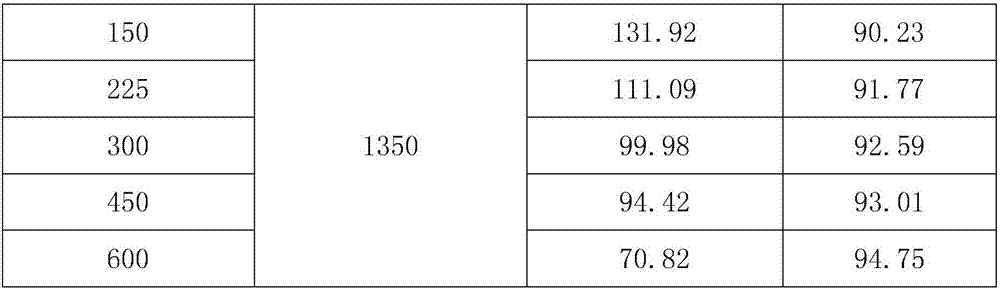

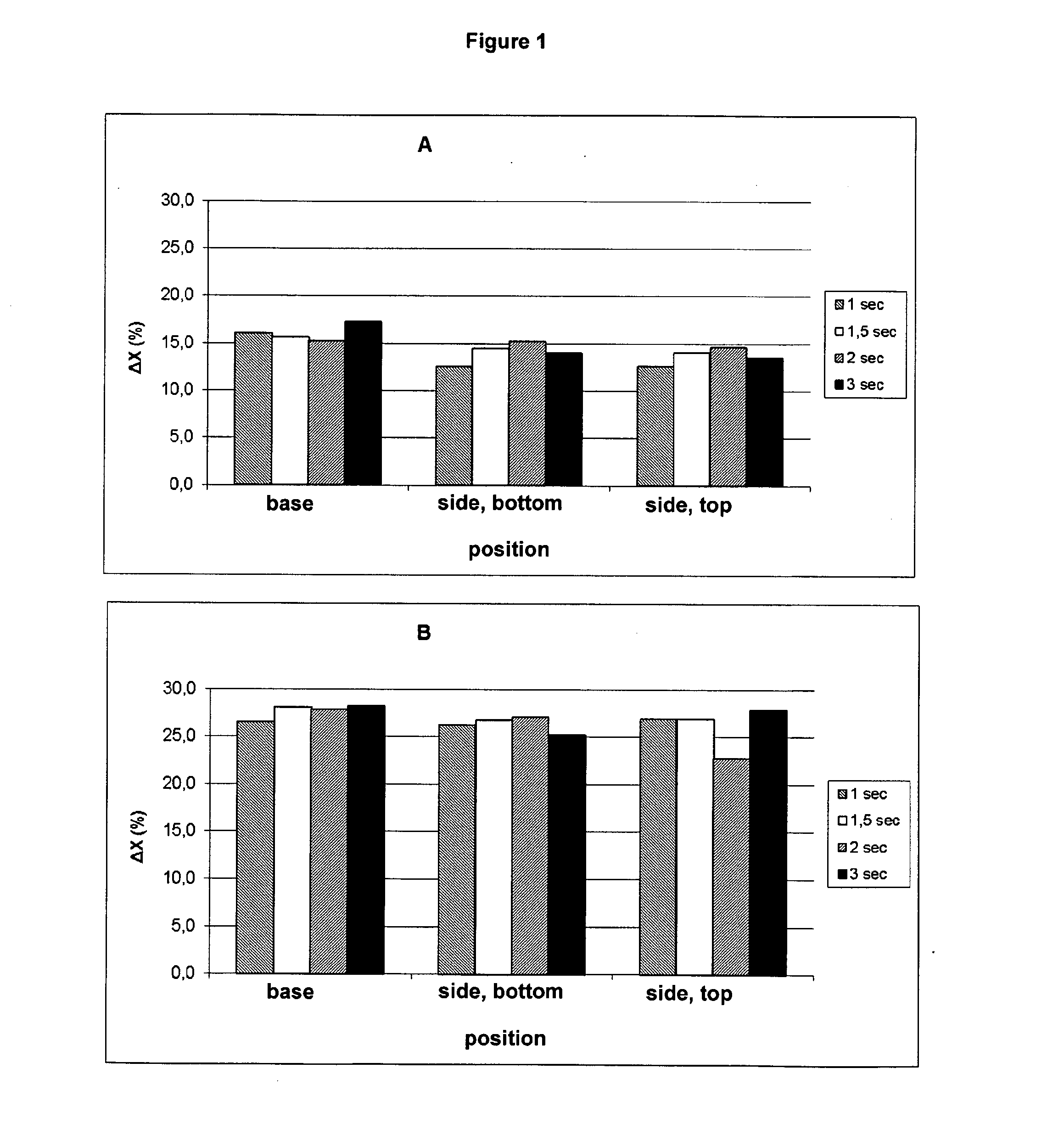

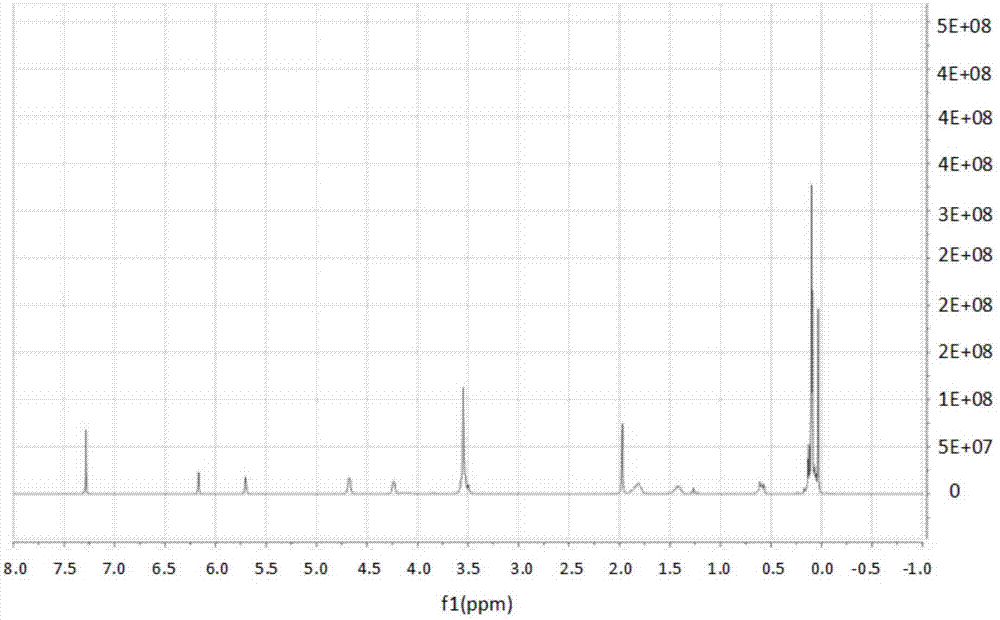

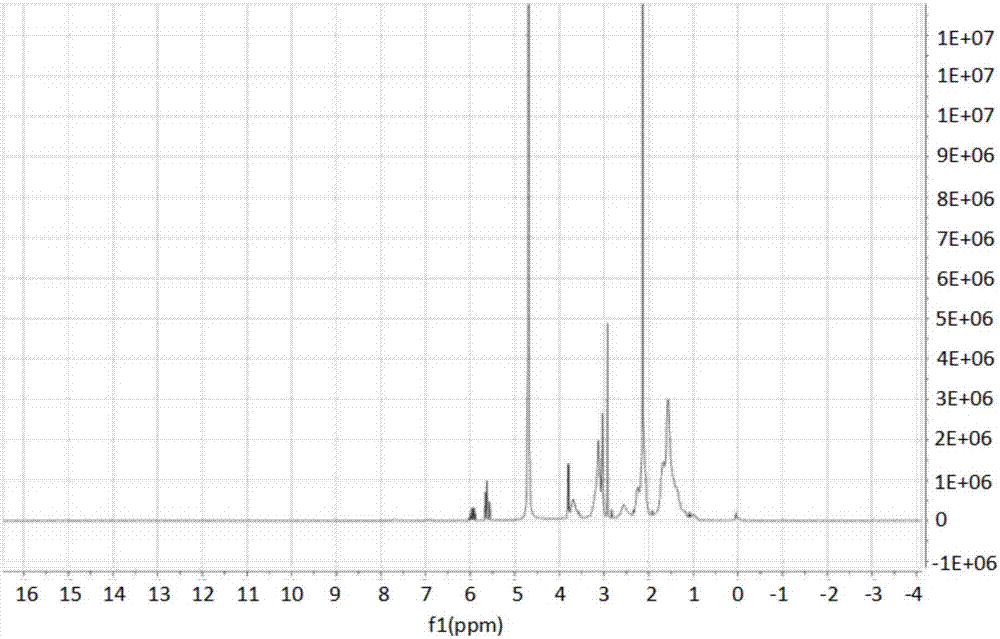

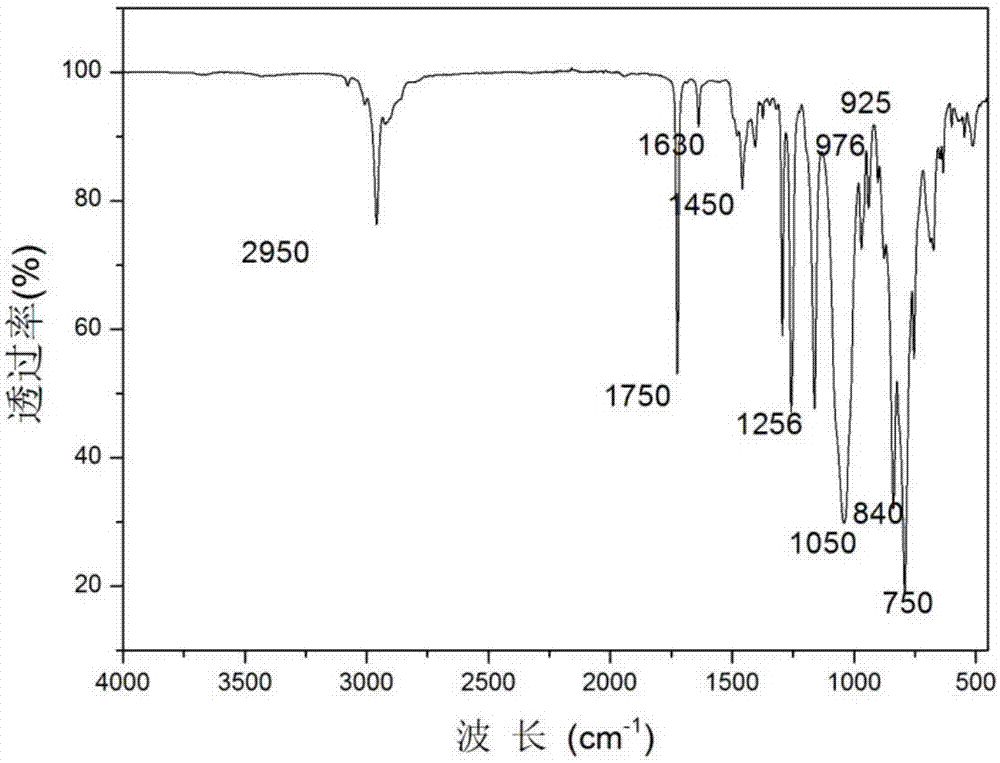

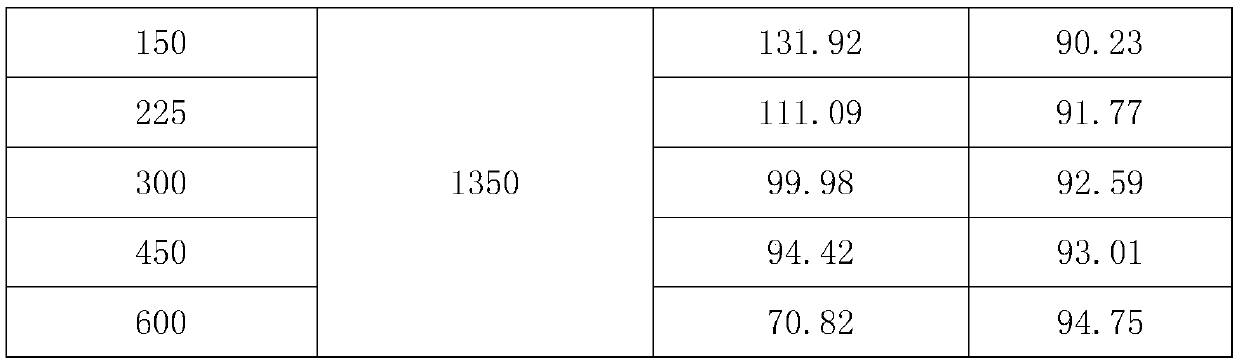

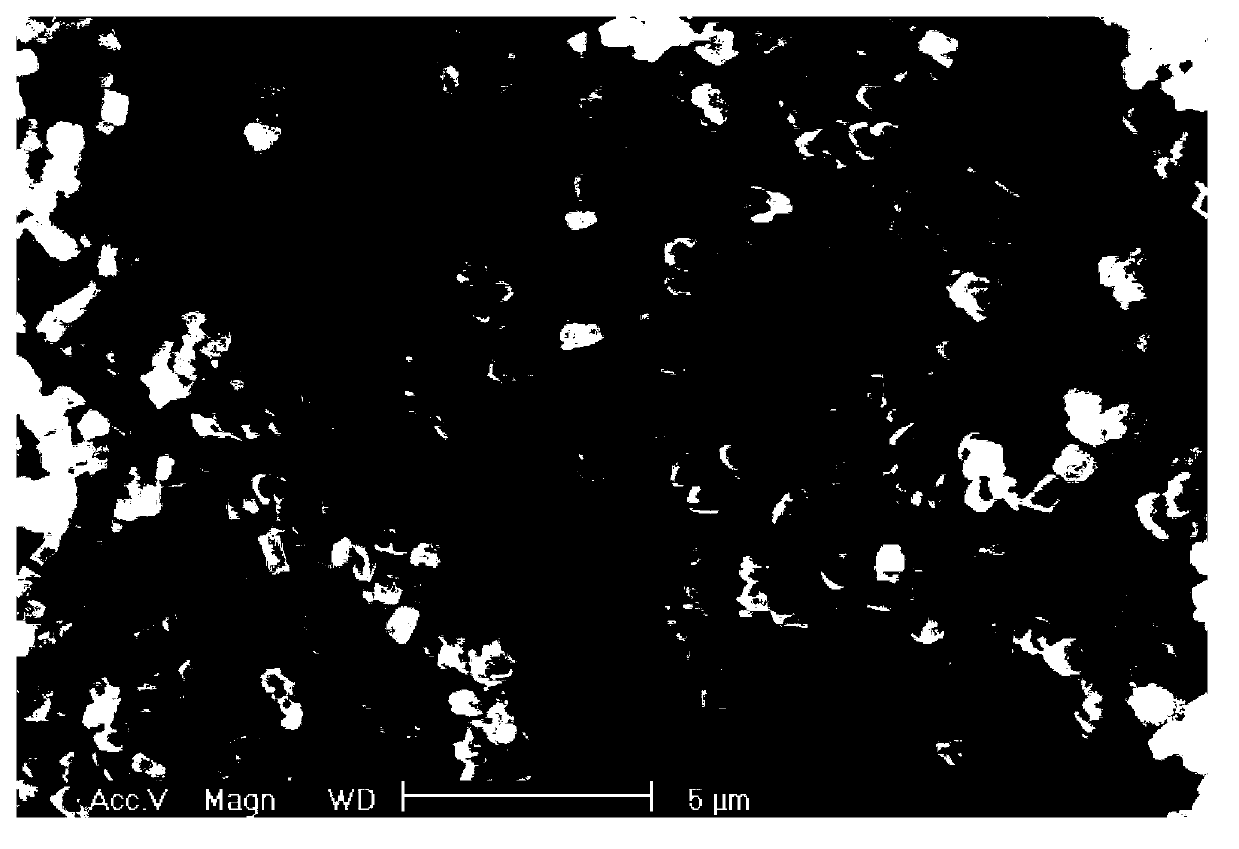

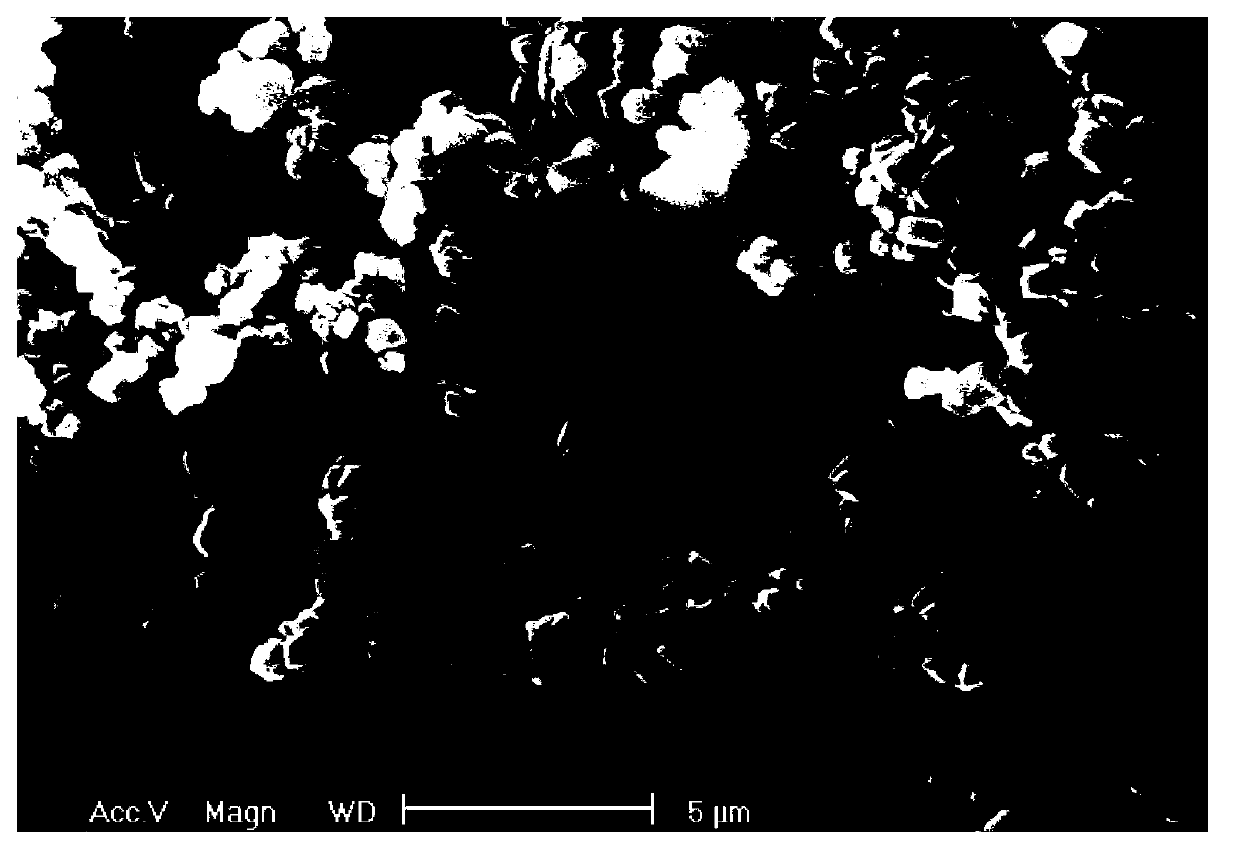

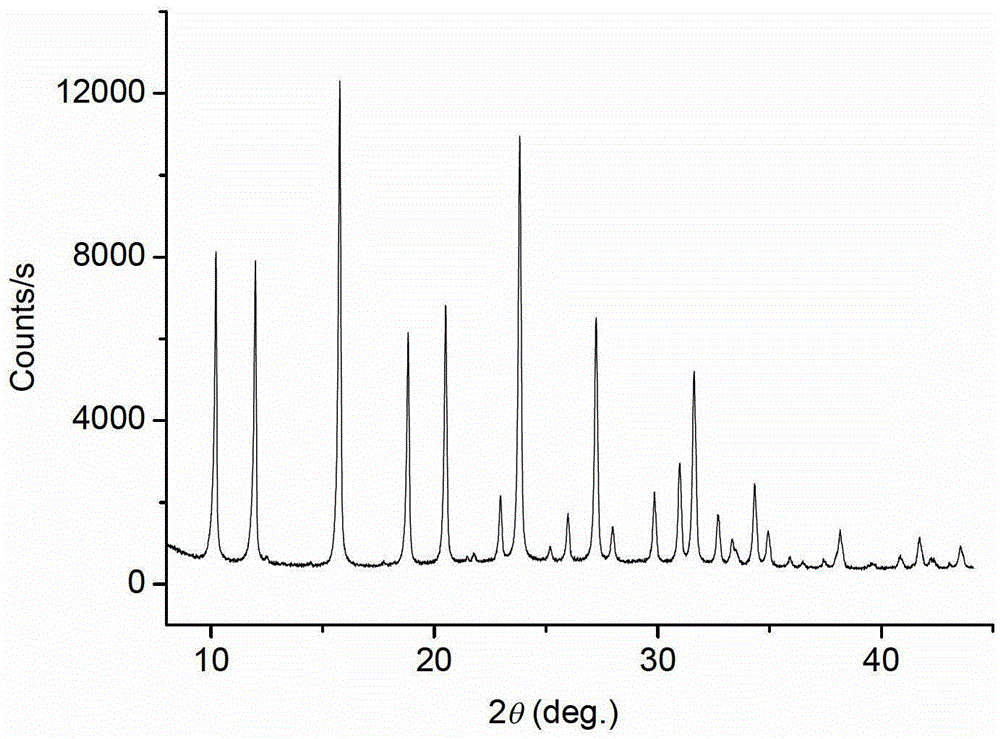

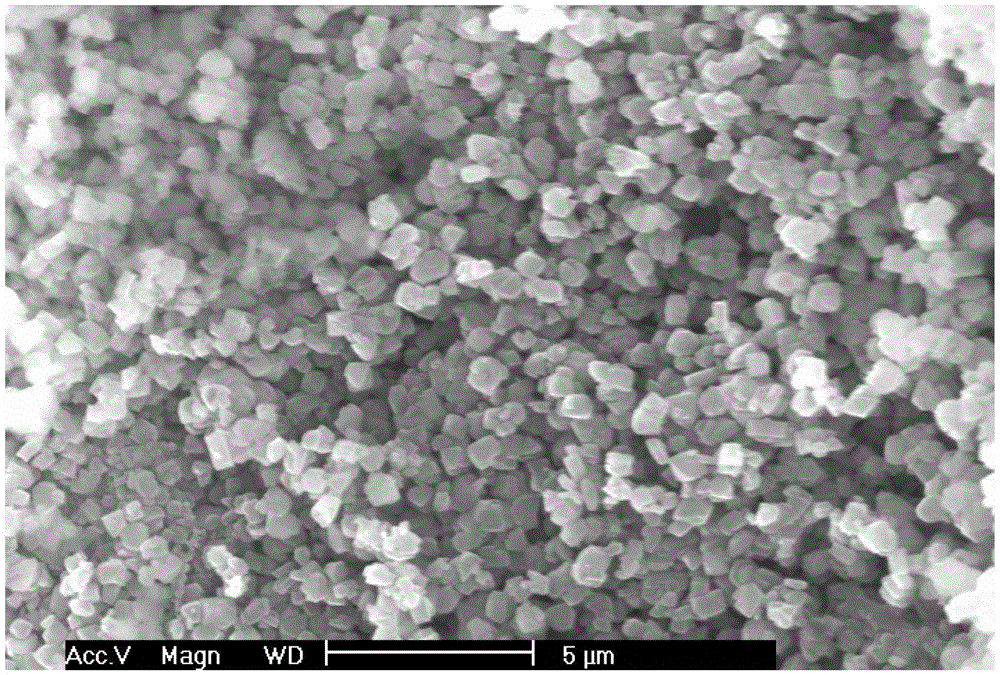

Crystalline form of 6-[(4r)-4-methyl-1,2-dioxido-1,2,6-thiadiazinan-2-yl]isoquinoline-1-carbonitrile

InactiveCN106459025ASuitable physical chemistryModerate stabilityOrganic active ingredientsNervous disorderCrystallographySelective androgen receptor modulator

This invention relates to a novel crystalline form of 6-[(4R)-4-methyl-1, 1-dioxido- 1,2,6-thiadiazinan-2-yl]isoquinoline-1-carbonitrile which is useful as a selective androgen receptor modulator (SARM), and to compositions thereof and suitable processes for the preparation thereof.

Owner:PFIZER INC

Non-dairy cream of mixed milk fat and preparation method thereof

Owner:SHANGHAI HI ROAD FOOD TECHNOLOGY CO LTD

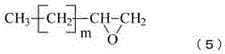

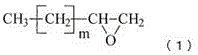

Chlorinated polyolefin resin composition

ActiveCN104185650BGood adhesionConvenient coatingNon-macromolecular adhesive additivesInksPolymer sciencePolyolefin

An object of the present invention is to provide a chlorinated polyolefin-based resin composition that has excellent adhesion to base materials such as polyolefin-based resin base materials, forms a good coating film, and has excellent stability, and can be used in coatings, primers, inks, It is useful for applications such as adhesives and heat sealants, and there is no problem in terms of safety. The present invention provides a chlorinated polyolefin-based resin composition containing an α-olefin oxide represented by the general formula (1) and / or an α,ω-olefin oxide represented by the general formula (2), [Chemical 1] [Formula 2] (In the formula, m is an integer from 3 to 26, and n is an integer from 2 to 28).

Owner:NIPPON PAPER IND CO LTD

Preparation method of cement foaming agent

InactiveCN107777913ARaw materials are easy to getWide variety of sourcesSodium bicarbonateFatty alcohol

The invention discloses a preparation method of a cement foaming agent, which belongs to the field of materials. A method for preparing a cement foaming agent, comprising the following steps: 1) preparing raw materials according to the following parts by weight: 20-30 parts of fatty alcohol polyoxyethylene ether sodium sulfate, 5-10 parts of starch, 10-20 parts of saponin, 20-30 parts of gelatin, 10-15 parts of sodium bicarbonate, 10-15 parts of n-hexane, 15-20 parts of trichlorofluoromethane. 2) Dissolve sodium bicarbonate in water and stir well; 3) Add sodium fatty alcohol polyoxyethylene ether sulfate, saponin, n-hexane, and trichlorofluoromethane into water in sequence, and stir well; 4) Add gelatin to water, Fully stir evenly to get the product. The cement foaming agent of the present invention has easy-to-obtain raw materials, wide sources, low cost, particularly strong foaming ability, large foam production per unit volume, very stable foam, no defoaming for a long time, fine foam, high foaming multiple, Good foam stability and other advantages.

Owner:NANJING YIHE CULTURE CREATIVE CO LTD

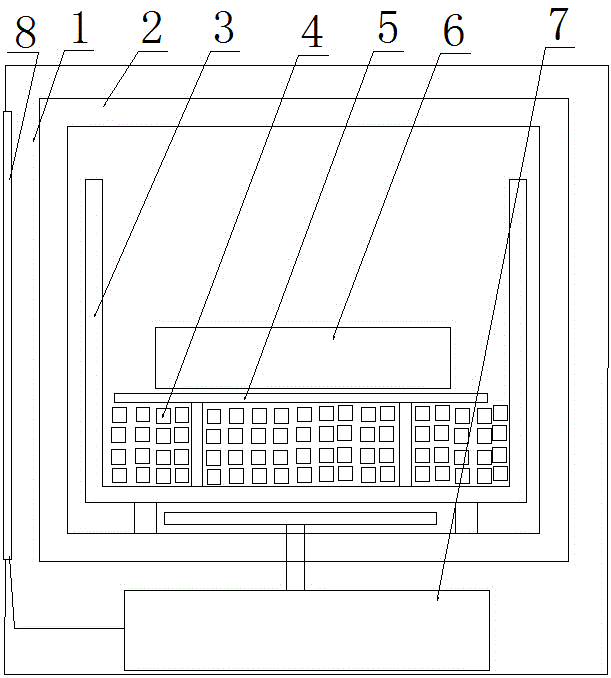

Local area network logistics distribution equipment in high-temperature anti-corrosion working condition environment

ActiveCN105600163AImprove insulation effectAvoid bruisesDomestic cooling apparatusLighting and heating apparatusProcess engineeringHeat conservation

The invention provides local area network logistics distribution equipment in a high-temperature anti-corrosion working condition environment. The local area network logistics distribution equipment comprises a cabinet body, a honeycomb heat-preservation rubber layer is arranged on the inner surface of the cabinet body, and a supporting and draining mechanism used for placing a cooling object is arranged at the bottom in the cabinet body. A cabinet door is arranged on the cabinet body and movably connected with the cabinet body. The local area network logistics distribution equipment is good in fresh-keeping effect and heat preservation effect, easy to implement and easy to apply and popularize in related industries and has a falling preventing function.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

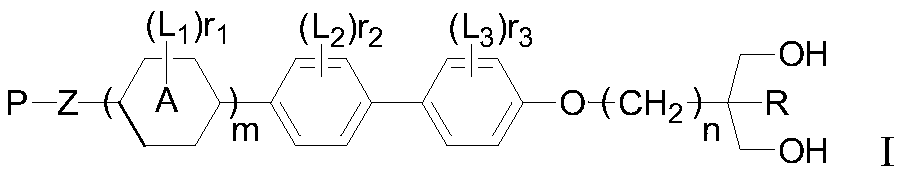

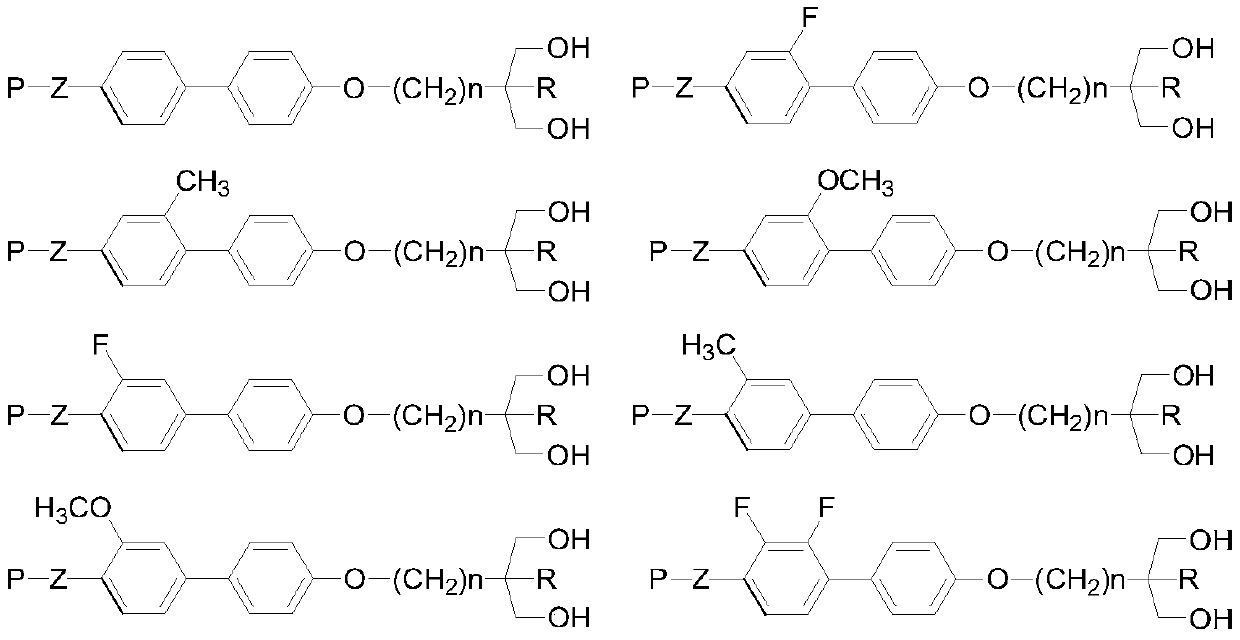

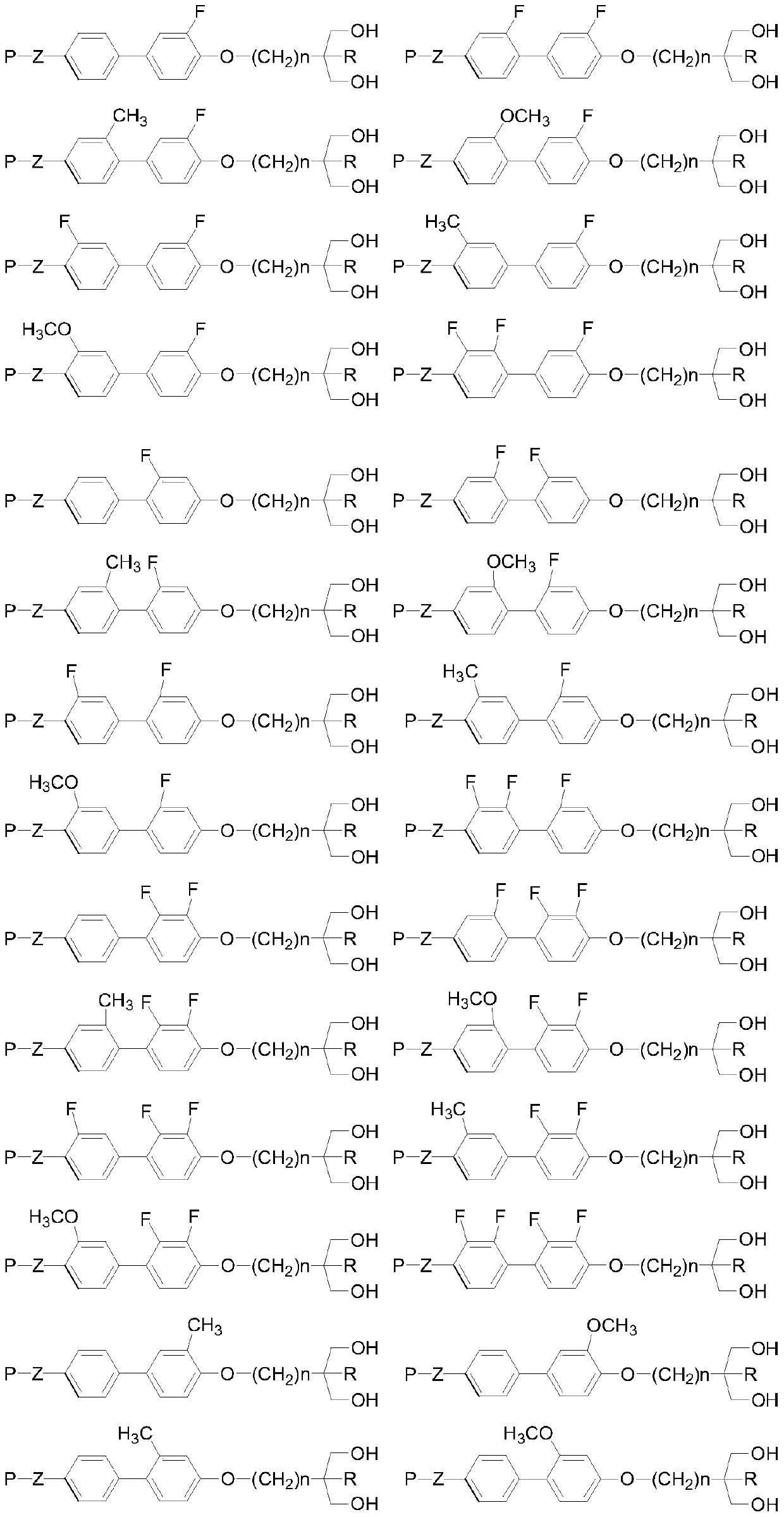

Novel self-alignment additive as well as preparation method and application thereof

InactiveCN111073663AAchieve vertical self-alignmentHigh negative dielectric anisotropyLiquid crystal compositionsCrystallographyCharge retention

The invention relates to a novel self-alignment additive, the structural formula of the novel self-alignment additive is as shown in the specification, the additive disclosed by the invention is addedinto a liquid crystal compound, so that vertical self-alignment of liquid crystal molecules can be realized under the condition of not containing a polyimide alignment layer. The negative dielectricanisotropy of the liquid crystal compound is extremely high; and the liquid crystal compound has a relatively high clearing point, relatively high optical anisotropy, moderate rotary viscosity and liquid crystal intersolubility, has an excellent working effect under a low-temperature condition, can effectively reduce driving voltage and improve the response speed of a liquid crystal display device, and has the characteristics of moderate optical anisotropy numerical value, high charge retention rate and the like. Moreover, the compound is low in price and stable in performance, and has wide application value.

Owner:BEIJING BAYI SPACE LCD MATERIALS TECH

A sound insulation device for a concert hall of a conservatory

InactiveCN105369922BNot perishableExcellent foaming abilitySound proofingEngineeringChemical stability

The invention discloses a sound insulation device for a concert hall of a conservatory of music, which comprises a pad body arranged on the wall of the concert hall, and a plurality of sound-absorbing mechanisms are arranged on the outside of the pad body, and the sound-absorbing mechanisms are evenly distributed on the pad body. The sound-absorbing mechanism is a strip structure, and its longitudinal section is a T-shaped structure. The invention integrates heat preservation, sound insulation and decoration, and meets the requirements of high temperature resistance, non-combustibility, light weight, high strength and excellent chemical stability. The sound insulation device for the concert hall of the Conservatory of Music can achieve heat preservation, sound absorption and decoration through one veneer construction. role.

Owner:NANYANG INST OF TECH

Flotation recovery method for high-calcium-magnesium high-argillaceous zinc carbonate

The invention relates to a high-calcium-magnesium high-argillaceous zinc carbonate flotation recovery method which comprises the following steps: (1) desliming flotation: taking lead-zinc sulfide flotation tailings as raw ores, adding a slime collecting agent, stirring and reacting for 3-6 minutes, and then desliming before zinc oxide flotation to respectively obtain slime-containing ore pulp and deslimed tailing ore pulp; (2) roughing zinc oxide: adding regulators of sodium carbonate, sodium sulfide, gangue inhibitor, lauryl amine acetate and butyl xanthate into the deslimed tailing pulp for roughing zinc to respectively obtain zinc rough concentrate pulp and roughed tailing pulp; (3) zinc oxide concentration: performing concentration operation on the zinc rough concentrate pulp twice to obtain zinc oxide concentrate; and (4) zinc oxide scavenging: performing one-time zinc oxide scavenging operation on the roughing tailing pulp to obtain zinc oxide scavenged tailings. According to the method, the floatability of the zinc oxide mineral can be remarkably enhanced, and better mineral separation technical indexes are obtained.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Cavity material made of mine tailing

InactiveCN109942264AReduce usageReduce manufacturing costSolid waste managementCeramicwareHardnessAdditive ingredient

The invention discloses a cavity material made of mine tailing, and relates to the technical field of cavities. The cavity material is prepared from, by weight, 50-55% of tailing, 15-20% of quicklime,5-10% of cement, 1-5% of phosphogypsum, 1-3% of nano-diamond powder, 5-10% of zirconium silicate, 60-65% of water and 0.1-0.3% of additives; the cavity adopts the mine tailing as the main ingredient,the accumulated mine tailing is comprehensively utilized, the pollution problem caused by accumulation of the tailing on the environment is solved, and meanwhile full utilization of the mine tailingis achieved, the dosage of cement is lowered, the production cost is reduced, and the energy conservation and environmental protection effects are significant, and the obvious economical efficiency isachieved; by means of the nano-diamond powder added in the cavity material, the wear resistance and fracture resistance of nano-diamond can be utilized, the wear resistance, hardness and fracture toughness of the cavity are effectively improved, the service life of the cavity is prolonged, and by means of zirconium silicate, the cavity has the advantages of being high in high temperature resistance and free of expansion at high temperature.

Owner:广东中人工程集团有限公司

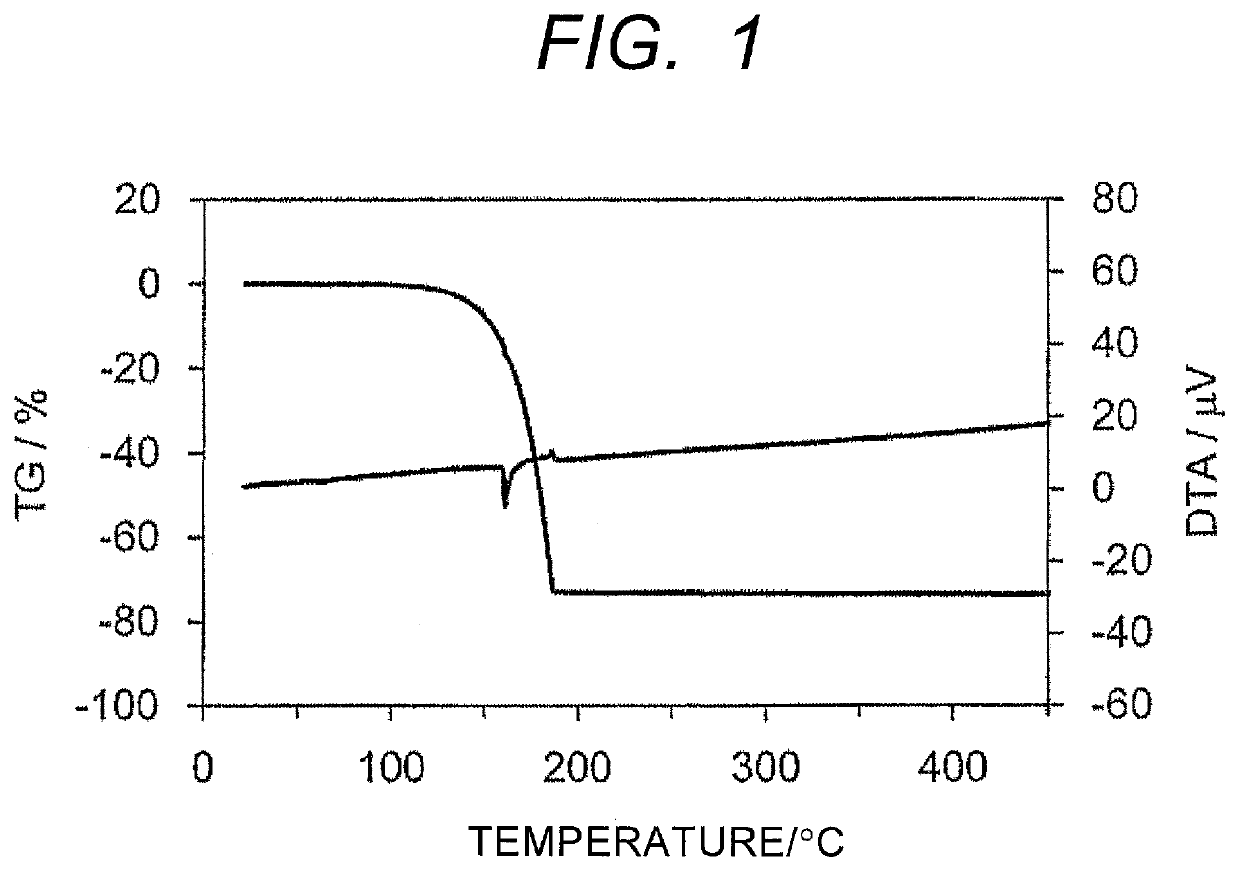

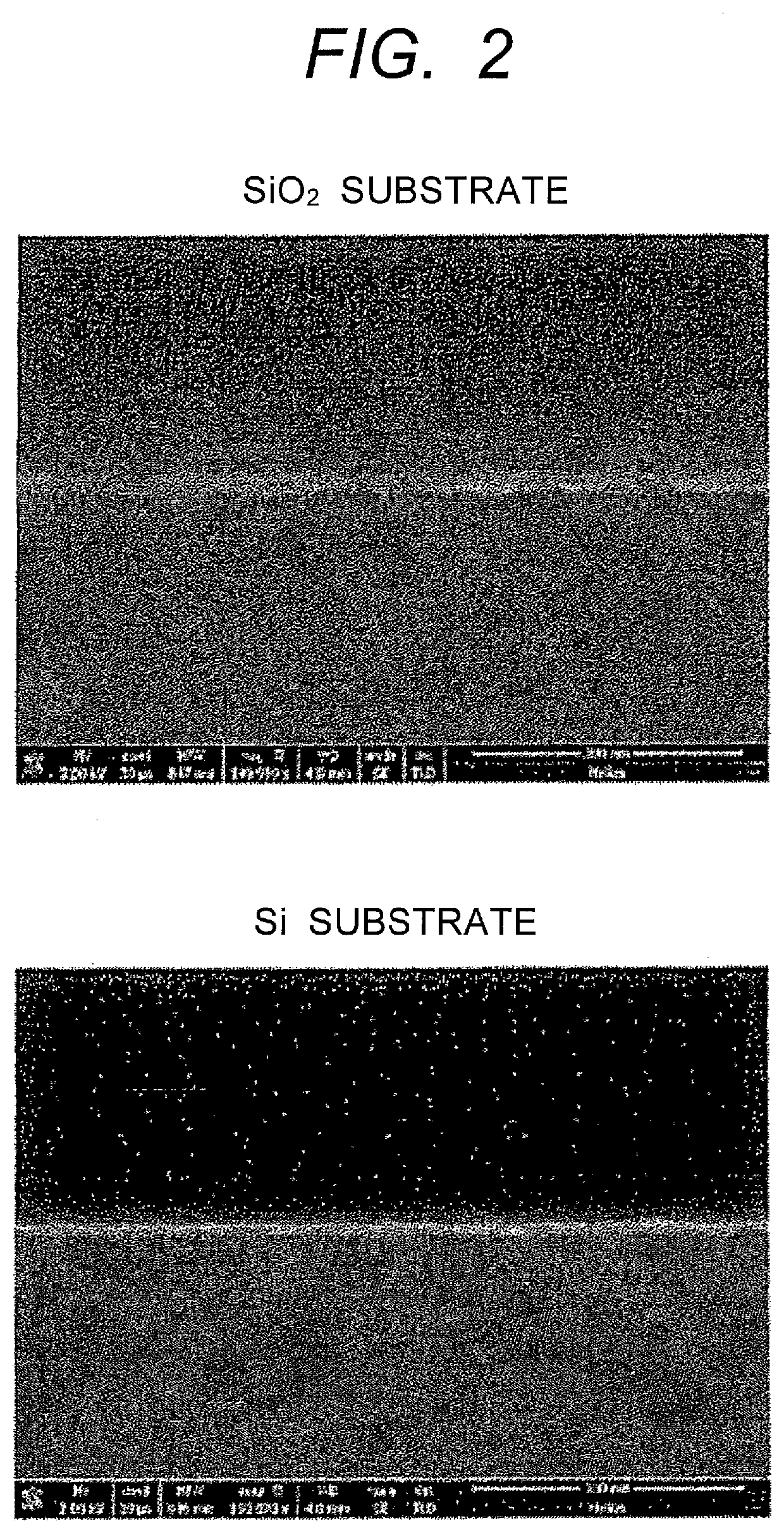

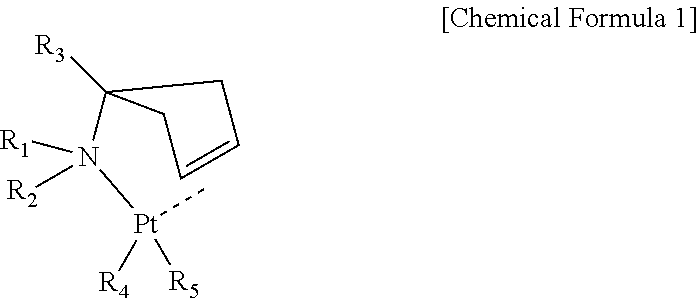

Raw material for vapor deposition including organoplatinum compound and vapor deposition method using the raw material for vapor deposition

ActiveUS20200148713A1Increase vapor pressureModerate thermal stabilityPlatinum organic compoundsSemiconductor/solid-state device manufacturingCyclopentenePhysical chemistry

A raw material for vapor deposition for producing a platinum thin film or a platinum compound thin film by a vapor deposition method. The raw material for vapor deposition includes an organoplatinum compound represented by the following formula, in which a cyclopentene-amine ligand and an alkyl ligand are coordinated to divalent platinum. The organoplatinum compound of the present invention has moderate thermal stability and can respond flexibly to severe film formation conditions, including a wider film formation area, higher throughput, and the like.(In the formula, R1, R2, and R3 are each any one of a hydrogen atom, an alkyl group, an alkenyl group, an alkynyl group, an amino group, an imino group, a cyano group, and an isocyano group, each having 4 or less carbon atoms, and R4 and R5 are each an alkyl group having 1 or more and 3 or less carbon atoms.)

Owner:TANAKA PRECIOUS METAL IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Crystalline form of 6-[(4r)-4-methyl-1,2-dioxido-1,2,6-thiadiazinan-2-yl]isoquinoline-1-carbonitrile Crystalline form of 6-[(4r)-4-methyl-1,2-dioxido-1,2,6-thiadiazinan-2-yl]isoquinoline-1-carbonitrile](https://images-eureka.patsnap.com/patent_img/192b60c7-8922-4508-b17e-b23d1bdba1b6/HPA0000231867000000011.png)

![Crystalline form of 6-[(4r)-4-methyl-1,2-dioxido-1,2,6-thiadiazinan-2-yl]isoquinoline-1-carbonitrile Crystalline form of 6-[(4r)-4-methyl-1,2-dioxido-1,2,6-thiadiazinan-2-yl]isoquinoline-1-carbonitrile](https://images-eureka.patsnap.com/patent_img/192b60c7-8922-4508-b17e-b23d1bdba1b6/HPA0000231867000000021.png)

![Crystalline form of 6-[(4r)-4-methyl-1,2-dioxido-1,2,6-thiadiazinan-2-yl]isoquinoline-1-carbonitrile Crystalline form of 6-[(4r)-4-methyl-1,2-dioxido-1,2,6-thiadiazinan-2-yl]isoquinoline-1-carbonitrile](https://images-eureka.patsnap.com/patent_img/192b60c7-8922-4508-b17e-b23d1bdba1b6/HPA0000231867000000031.png)