Siloxane quaternary ammonium salt modified amphiphilic polymer ultra-heavy oil viscosity reducer and preparation method and application thereof

A technology of amphiphilic polymer and viscosity reducer, which is applied in drilling compositions, chemical instruments and methods, etc., can solve the problem of unmentioned application effect of high salinity ultra-heavy oil, and achieve good viscosity reduction. effect, enhance temperature and salt resistance and anti-aging ability, the effect of simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Silicone quaternary ammonium salt monomer containing double bond S 0 Synthesis:

[0065] Add 5.26 g of dimethylaminoethyl methacrylate, 1-(4-bromobutyl)-1,1,3,3,5, 14.35g of 5,5-heptamethyltrisiloxane and 30g of acetone, stir well. After reacting at a temperature of 55° C. for 60 hours, it was cooled to room temperature; most of the solvent and some unreacted raw materials were removed by rotary evaporation under reduced pressure. After cooling the remaining distillate to room temperature, add 50.0 mL of diethyl ether, cool to 0°C to crystallize, then filter with suction, wash with diethyl ether three times, and dry in vacuum at 45°C for 24 hours to obtain a siloxane-based quaternary ammonium salt monomer containing a double bond S 0 , yield 12.25g, yield rate is 71.18%;

[0066] S 0 The synthetic reaction formula is as follows:

[0067]

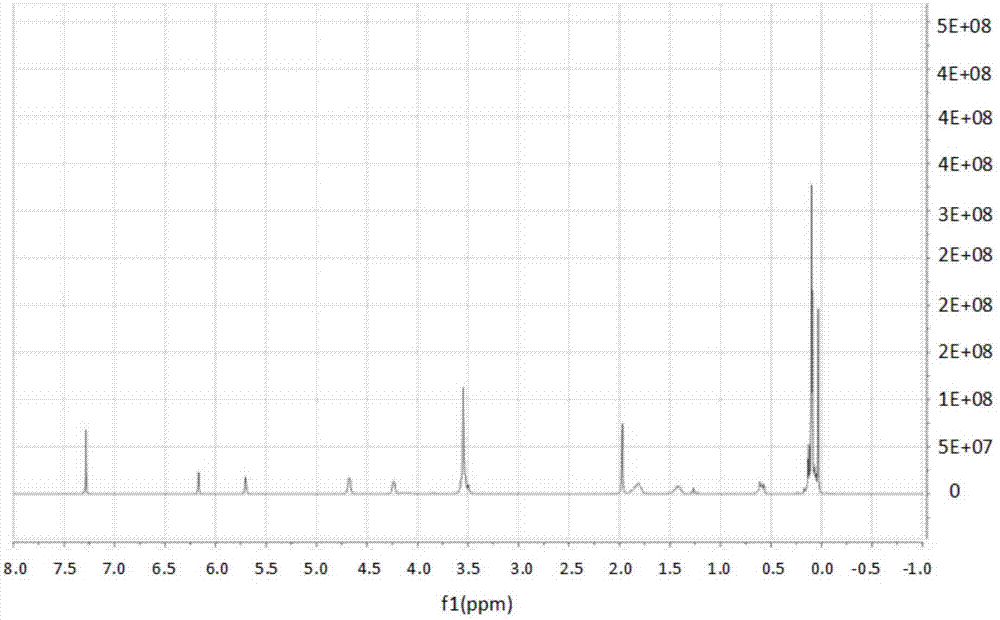

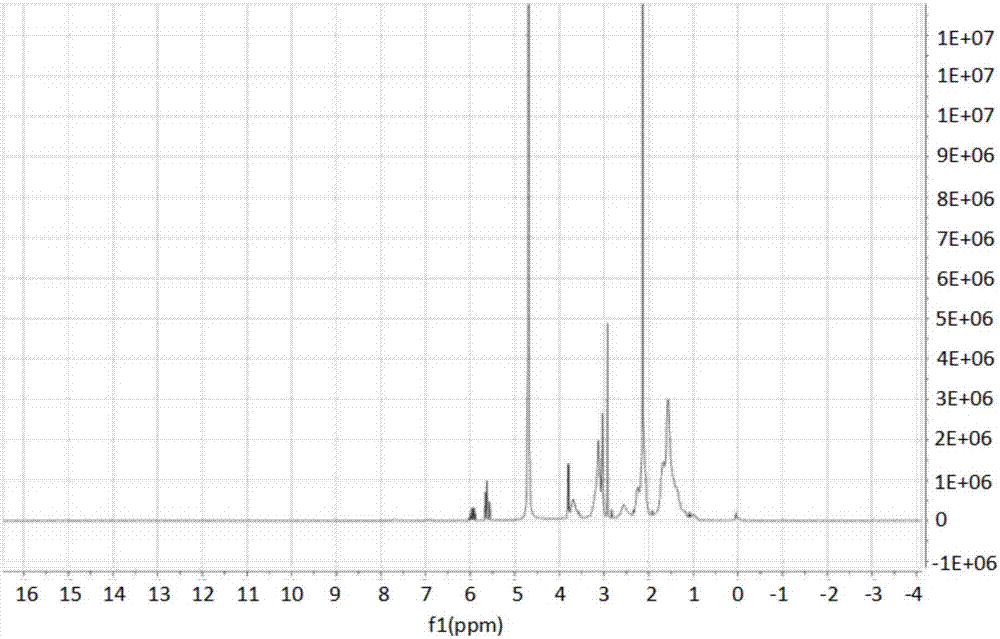

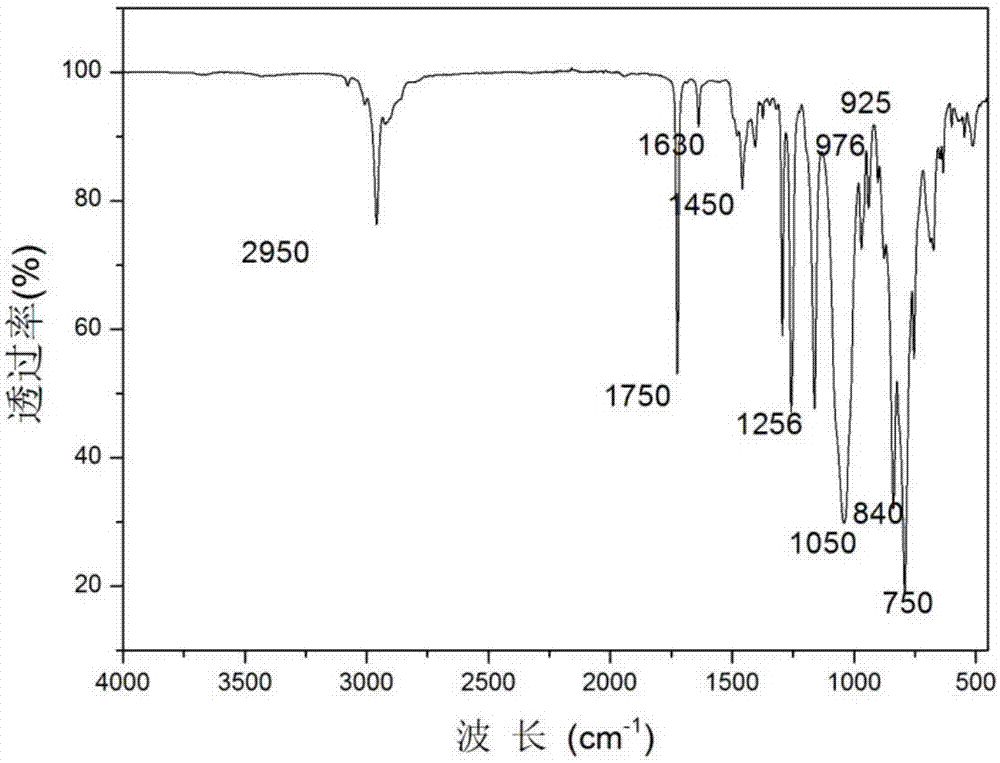

[0068] figure 1 The siloxane-based quaternary ammonium salt monomer S containing double bonds prepared in this embodiment ...

Embodiment 2

[0074] Silicone quaternary ammonium salt monomer containing double bond S N Synthesis:

[0075] The preparation steps are as described in Example 1, except that: 5.22 g of (N,N-dimethylaminoethyl) methacrylamide is weighed instead of dimethylaminoethyl methacrylate; other conditions are completely the same as in Example 1. Preparation of siloxane-based quaternary ammonium salt monomer S containing double bonds N 12.85g, the yield is 74.84%;

[0076] S N The synthetic reaction formula is as follows:

[0077]

Embodiment 3

[0079] Amphiphilic polymer super heavy oil viscosity reducer PADS modified by silicone quaternary ammonium salt 0 Synthesis of -1:

[0080] Weigh successively 17.21g of acrylamide, 9.79g of dimethyl diallyl ammonium chloride, 3.00g of the double bond-containing siloxane quaternary ammonium salt monomer S prepared in Example 1 0 , 250.00g of water, put it into a four-necked flask equipped with a thermometer, an air guide tube, a reflux condenser and a stirring device, blow nitrogen under stirring, heat up to 65°C after 30 minutes, and weigh 0.15g of azobisisobutylamidine salt Acetyl acid (AIBA), after dissolving with 20.00g of water, divided into 2 batches with an interval of 15 minutes; every 15 minutes, dropwise added 10g of initiator aqueous solution to the reaction bottle, after completion, kept the reaction temperature at 65°C, and reacted for 8 hours to obtain the reaction liquid; after the reaction liquid was cooled to room temperature, it was poured into 500mL acetone,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com