Chlorinated polyolefin resin composition

A technology of chlorinated polyolefin and resin composition, applied in the direction of adhesive additives, non-polymer adhesive additives, applications, etc., can solve the problems of strong mutagenicity and use restrictions, and achieve the effect of excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

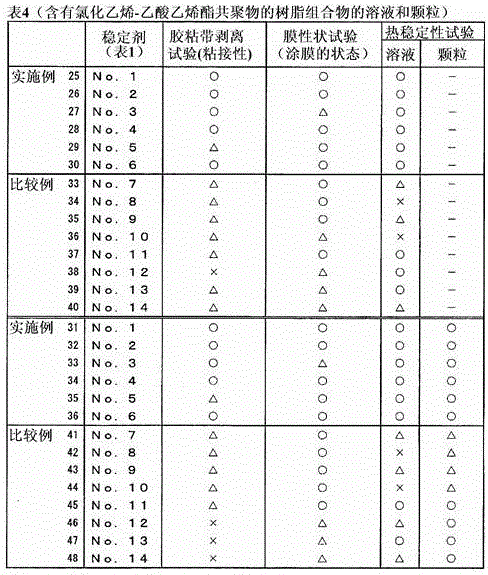

Embodiment 1

[0120] 4 kg of crystalline polypropylene having a melt index of 14 g / min (measured according to JIS K7210) and a melting point of 160° C. was charged into a glass-lined reaction vessel, and 50 L of chloroform was added thereto. The inside of the kettle was pressurized to 0.3 MPa in terms of gauge pressure, and it was fully dissolved at a temperature of 110°C. Then, as a radical reaction initiator, 4 g of tert-butylperoxyisopropyl carbonate was added, and chlorine gas was blown in while maintaining the pressure inside the tank at 0.3 MPa to obtain a chlorine content of 30% by weight and a molecular weight of 180,000. Chloroform solution of chlorinated polypropylene. Next, after concentrating the chloroform solution using an evaporator, epoxy compound No. 1 in Table 1 was added as a stabilizer, and chloroform as a reaction solvent was replaced with toluene. Thus, a solution of a chlorinated polyolefin-based resin composition having a solid content concentration of 20% by weight...

Embodiment 2

[0122] Except having used the epoxy compound No. 2 in Table 1 as a stabilizer, the procedure was the same as Example 1, and the solution of the chlorinated polyolefin resin composition was obtained, and the same test was performed. The results are shown in Table 2.

Embodiment 3

[0124] Except having used the epoxy compound No. 3 in Table 1 as a stabilizer, the procedure similar to Example 1 was used to obtain the solution of the chlorinated polyolefin resin composition, and the same test was performed. The results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com