Novel self-alignment additive as well as preparation method and application thereof

An additive and self-aligning technology, applied in chemical instruments and methods, liquid crystal materials, etc., can solve problems such as constraints, time-consuming, and increased production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

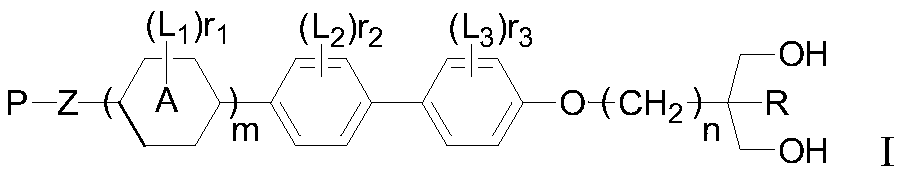

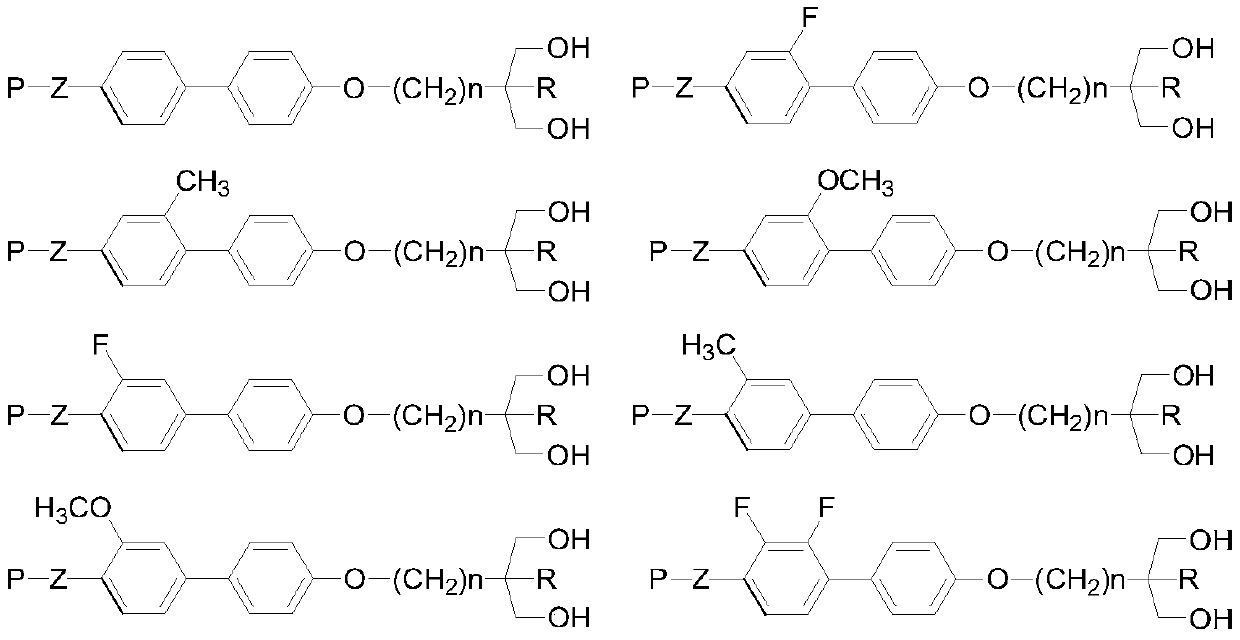

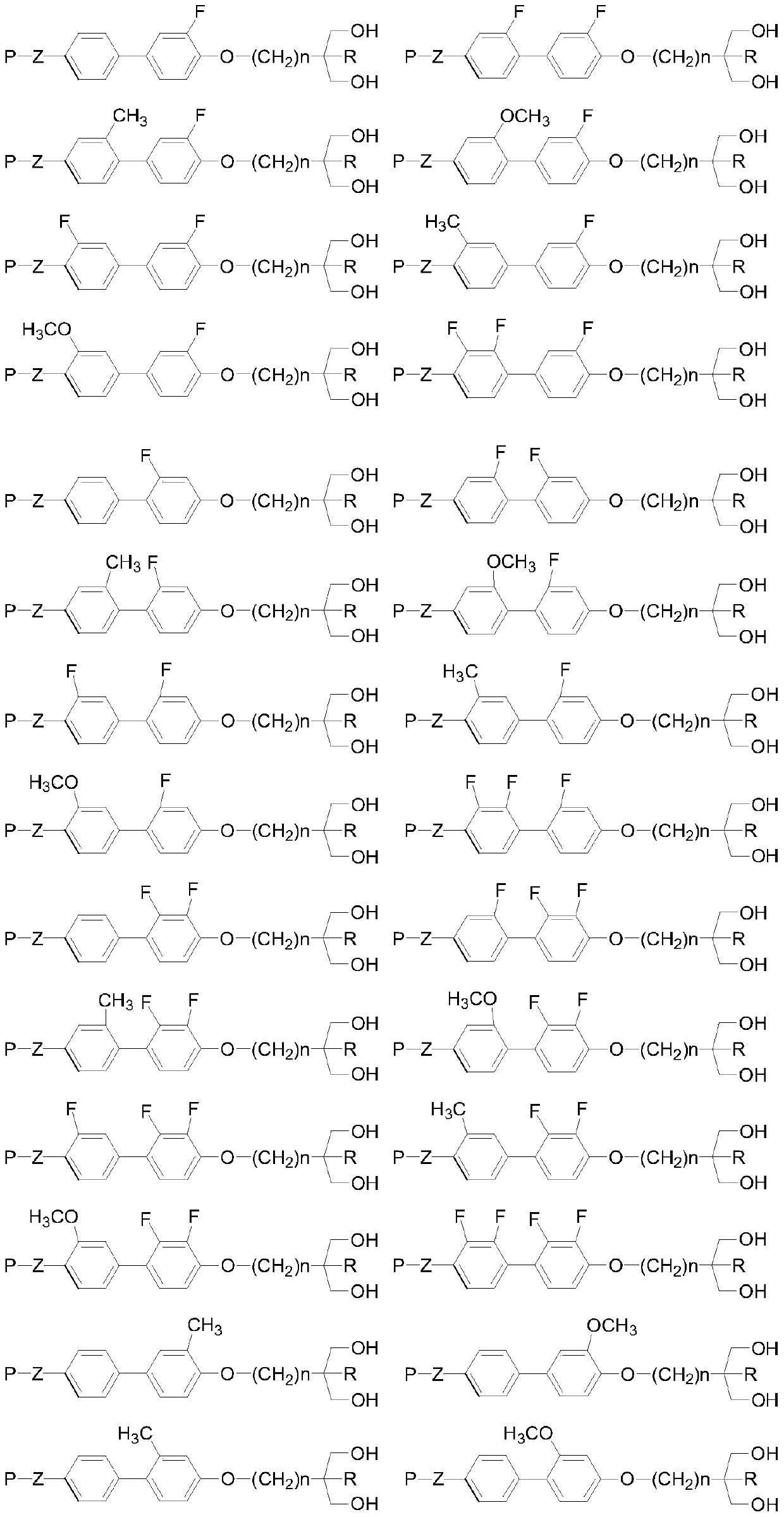

[0127] The structural formula of the liquid crystal compound is:

[0128]

[0129] The synthetic route for preparing compound BYLC-01 is as follows:

[0130]

[0131] Specific steps are as follows:

[0132] (1) Synthesis of compound BYLC-01-1:

[0133] Under nitrogen protection, add 45g (0.288mol), 150ml tetrahydrofuran, add dropwise 0.35mol n-butyllithium n-hexane solution at -70~-80°C under temperature control, react with temperature control for 1 hour after dropping, add 43.7g boric acid dropwise under temperature control at -60~-70°C Trimethyl ester (0.41mol), and then naturally warmed to -30°C. Add 400ml of 2M hydrochloric acid aqueous solution for acidification, perform conventional post-treatment, and recrystallize petroleum ether to obtain 54.3g of light yellow solid (compound BYLC-01-1, 0.272mol), HPLC: 99.7%, yield: 94.3%.

[0134] (2) Synthesis of compound BYLC-01-2:

[0135] Under nitrogen protection, add 54.3g compound BYLC-01-1 (0.272mol), 59.8g compo...

Embodiment 2

[0147] The structural formula of the liquid crystal compound is:

[0148]

[0149] The synthetic route for preparing compound BYLC-02 is as follows:

[0150]

[0151] by replace Other reaction conditions are with embodiment 1.

[0152] The obtained white solid BYLC-02 was analyzed by GC-MS, and the m / z of the product was 384.1 (M+).

[0153] 1 H-NMR (300MHz, CDCl 3 ):0.95-1.65(m,9H),1.85-2.65(m,2H),3.35-4.15(m,6H),5.45-6.26(m,3H),6.35-7.55(m,8H).

Embodiment 3

[0155] The structural formula of the liquid crystal compound is:

[0156] BYLC-03

[0157] by instead of B(OH) 3 , other conditions are with embodiment 1.

[0158] The obtained white solid BYLC-03 was analyzed by GC-MS, and the m / z of the product was 412.1 (M+).

[0159] 1 H-NMR (300MHz, CDCl 3 ):0.95-1.65(m,9H),1.85-2.65(m,5H),3.35-4.15(m,6H),5.35-6.26(m,3H),6.35-7.55(m,9H).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com