A self-alignment additive and a preparation method and application thereof

An additive and self-alignment technology, applied in chemical instruments and methods, optics, instruments, etc., can solve problems such as time-consuming, weak anchoring ability of liquid crystal molecules, and application limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

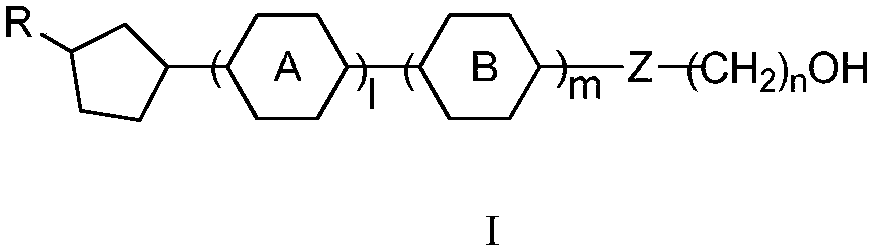

Image

Examples

Embodiment 1

[0081] Synthesis of Embodiment 1 BYLC-01

[0082] The structural formula of the liquid crystal compound is:

[0083]

[0084] The synthetic route for preparing compound BYLC-01 is as follows:

[0085]

[0086] Specific steps are as follows:

[0087] (1) Synthesis of compound BYLC-01-1:

[0088] Under the protection of nitrogen, add 40.0g of p-bromoanisole and 280ml of tetrahydrofuran to the reaction flask, and add 0.26mol of n-butyllithium n-hexane solution dropwise at -70~-80°C under temperature control.

[0089] 32.0 g of trimethyl borate was added dropwise at -60 to -70°C under temperature control, and then returned to -30°C naturally.

[0090] Add 400 ml of 2M hydrochloric acid aqueous solution for acidification, perform conventional post-treatment, and recrystallize petroleum ether to obtain 28.3 g of light yellow solid (compound BYLC-01-1), HPLC: 99.7%, yield: 85.7%.

[0091] (2) Synthesis of compound BYLC-01-2:

[0092] Under nitrogen protection, 28.3g of com...

Embodiment 2

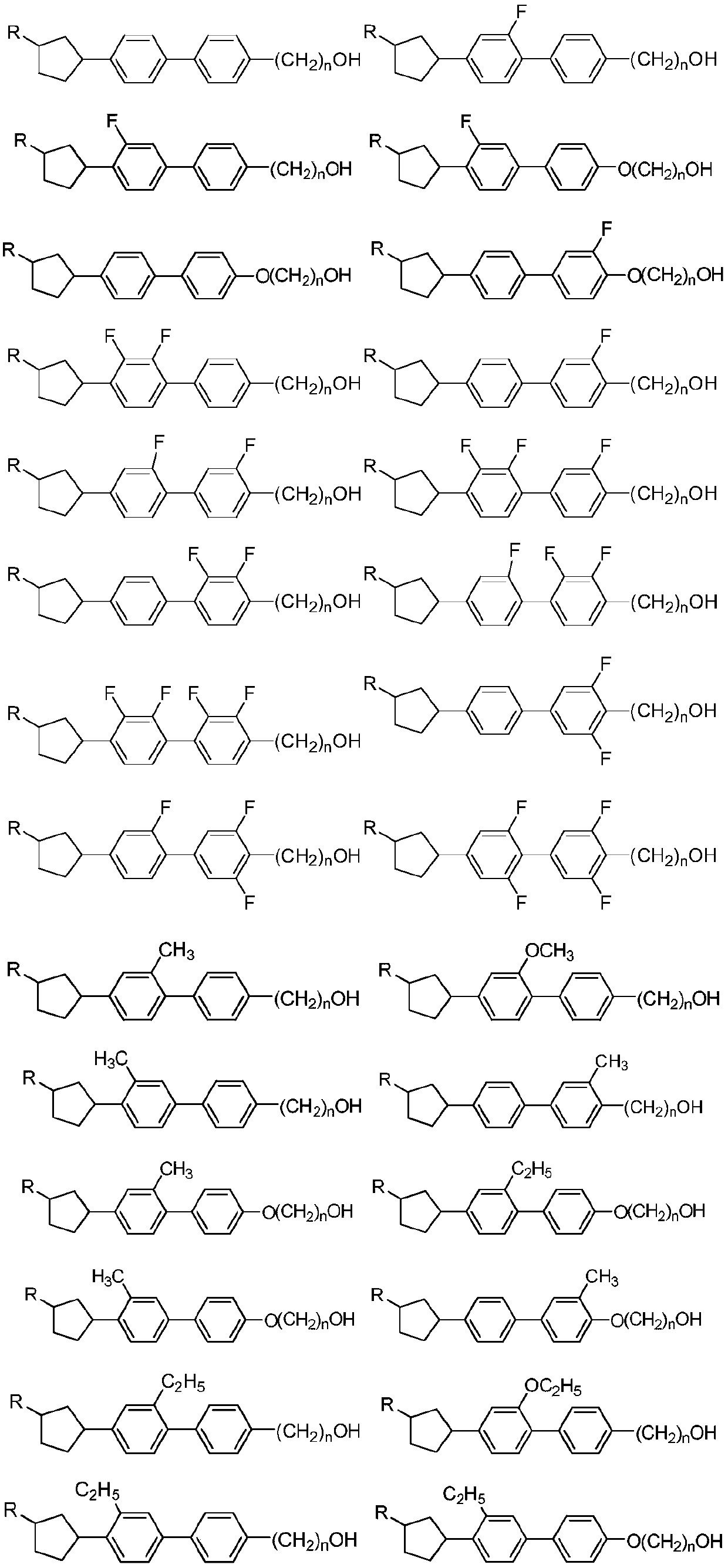

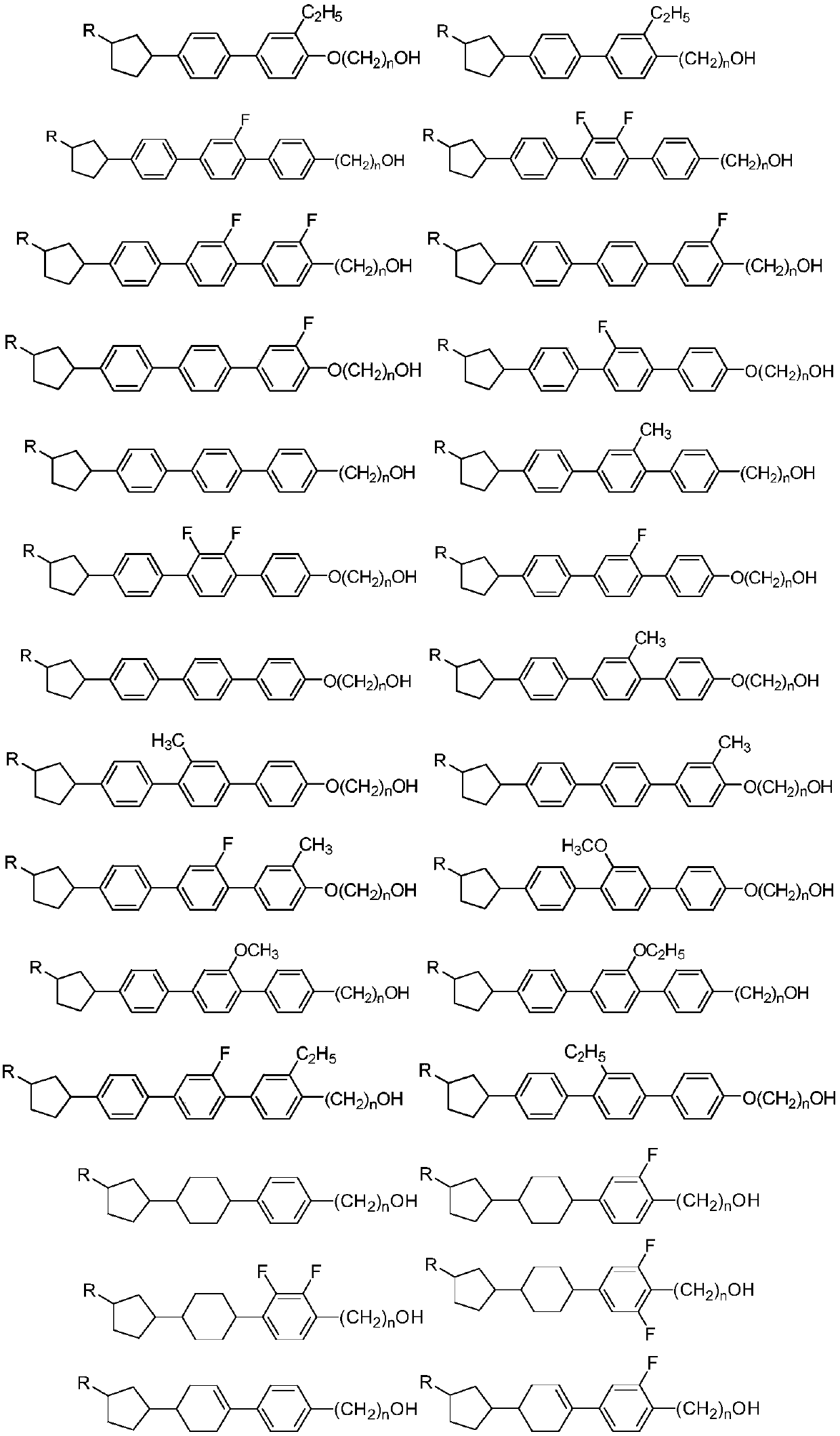

[0098] According to the technical scheme of Example 1, the following compounds can be synthesized by simply replacing the corresponding raw materials without changing any substantive operations:

[0099]

[0100]

[0101] R represents a hydrogen atom or an alkyl group with 1-5 carbon atoms, wherein, one or more non-adjacent CH 2 The radicals can be replaced independently of each other by -O- not directly connected to each other; n represents 0, 1, 2, 3, 4 or 5.

Embodiment 3

[0102] Synthesis of Embodiment 3 BYLC-02

[0103] The structural formula of the liquid crystal compound is:

[0104]

[0105] The synthetic route for preparing compound BYLC-02 is as follows:

[0106]

[0107] Specific steps are as follows:

[0108] (1) Synthesis of compound BYLC-02-1:

[0109] Add 50.0 g of p-bromoanisole and 450 ml of tetrahydrofuran to the reaction flask, add dropwise 0.315 mol of n-butyl lithium in n-hexane solution at -70 to -80°C under temperature control, and react for 1 hour under temperature control;

[0110] A solution consisting of 46.0 g of 4-(3-ethylcyclopentyl) cyclohexanone and 150 ml of tetrahydrofuran was added dropwise at a temperature of -70 to -80°C, and then the temperature was naturally returned to -30°C.

[0111] Add 500ml of 2M hydrochloric acid aqueous solution for acidification and conventional post-treatment to obtain 76.2g of light yellow liquid (compound BYLC-02-1), GC: 93.8% (cis + trans), yield: 96.4%.

[0112](2) Synth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com