A novel liquid crystal vertical alignment agent and its preparation method and application

A technology of vertical alignment and alignment agent, applied in the field of self-alignment additives and their preparation, can solve the problems of increased production cost, application limitation, long time consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

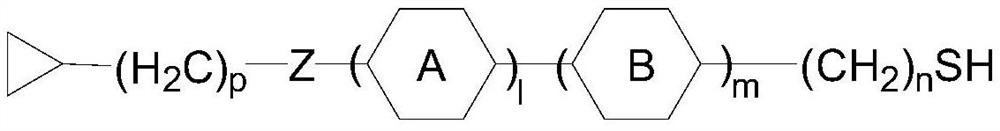

Method used

Image

Examples

Embodiment 1

[0042]The structural formula of the vertical alignment agent is:

[0043]

[0044]The synthetic route to prepare compound BYLC-01 is as follows:

[0045]

[0046]Specific steps are as follows:

[0047](1) Synthesis of compound BYLC-01-1:

[0048]Add 20g to the reaction flask(0.073mol), 0.8g 4-(dimethylamino)-pyridine, add 300ml of dichloromethane to dissolve it; control the temperature at 10-15℃ and add 13ml of pyridine dropwise; cool the reaction solution, control the temperature at 0-5℃, and slowly drop Add 6.3ml of methanesulfonyl chloride (0.081mol); stir for 10h. Add 400 ml of 2M hydrochloric acid aqueous solution for acidification, perform conventional post-treatment, and recrystallize from acetonitrile to obtain 24.3 g of colorless crystals (compound BYLC-01-1, 0.069 mol), HPLC: 99.8%, yield: 94.5%.

[0049](2) Synthesis of compound BYLC-01-2:

[0050]Under the protection of nitrogen, 24.3 g of compound BYLC-01-1 (0.069 mol) and 61.6 g of potassium thioacetate were added to the reaction flask, disso...

Embodiment 2

[0056]The structural formula of the vertical alignment agent is:

[0057]

[0058]The synthetic route to prepare compound BYLC-02 is as follows:

[0059]

[0060]Specific steps are as follows:

[0061](1) Synthesis of compound BYLC-02-1:

[0062]Add 10g to the reaction flask(0.034mol), 0.4g 4-(dimethylamino)-pyridine, add 150ml of dichloromethane to dissolve it; control the temperature at 10-15℃ and add 7ml pyridine dropwise; cool the reaction solution, control the temperature at 0-5℃, and slowly drop Add 3.2ml of methanesulfonyl chloride (0.039mol); stir for 10h. Add 200ml of 2M hydrochloric acid aqueous solution for acidification, perform conventional post-treatment, and recrystallize from acetonitrile to obtain 12.1g of colorless crystals (compound BYLC-02-1, 0.031mol), HPLC: 99.7%, yield: 93.2%.

[0063](2) Synthesis of compound BYLC-02-2:

[0064]Under the protection of nitrogen, 12.1g of compound BYLC-02-1 (0.031mol) and 30.5g of potassium thioacetate were added to the reaction flask, dissolved in 40...

Embodiment 3

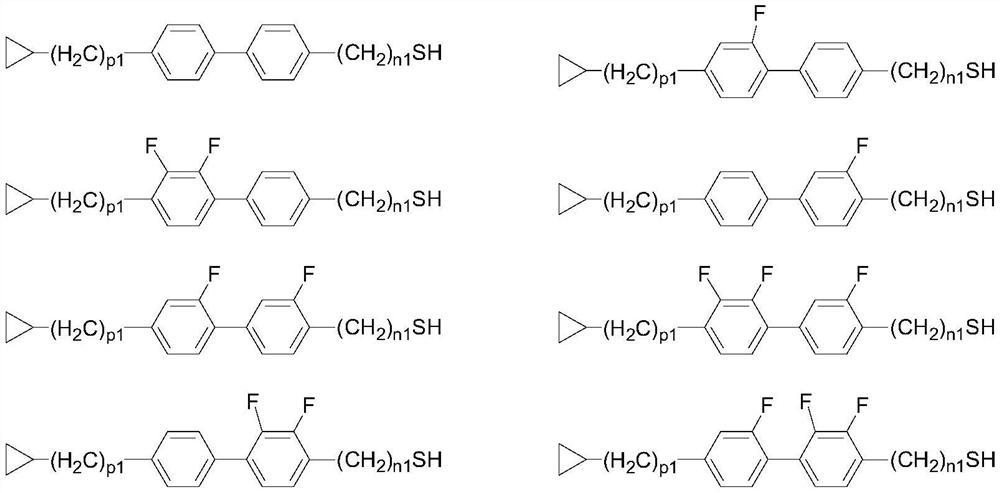

[0070]According to the technical solutions of Embodiment 1 and Embodiment 2, the following liquid crystal compounds can be synthesized by simply replacing the corresponding raw materials without changing any substantial operations:

[0071]

[0072]

[0073]In the above formulas, p1 represents 1, 2, 3, or 4; n1 represents 0, 1, 2, 3, 4, or 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com