Flotation recovery method for high-calcium-magnesium high-argillaceous zinc carbonate

A recovery method, high calcium and magnesium technology, applied in flotation, solid separation, etc., can solve the problems of high chemical consumption, poor selectivity, and not widely used, and achieve strong loading capacity, enhanced electronegativity, and strong inhibition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

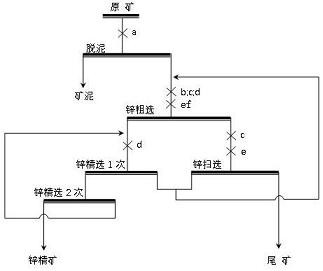

Image

Examples

Embodiment 1

[0051] The Zn content in a lead-zinc sulfide flotation tailing in Sichuan is about 1.50%. The zinc minerals are mainly smithsonite, followed by hemimorphite, hydrozinc, etc. The zinc oxidation rate is 80%. The main gangue minerals are Quartz, calcite, dolomite, chlorite, mica, etc., the content of CaO and MgO in the mineral sample is relatively high, and calcium and magnesium gangue minerals are easily argillized, of which the content of CaO is 24.3%, and the content of MgO is 18.2%, - The content of 10μm particle size reaches 40.5%, which belongs to high calcium magnesium and high muddy zinc-containing tailings. The closed circuit test results of Example 1 are shown in Table 1.

[0052] The specific process is as follows:

[0053] ⑴ Desilting flotation:

[0054] The lead-zinc sulfide flotation tailings are used as raw ore, and the amount of sludge collector (a) is 50g / t based on the dry ore weight of the raw ore. mud, respectively, to obtain mud-containing slurry and desli...

Embodiment 2

[0066] The content of Zn in a lead-zinc sulfide flotation tailing in Gansu is about 3.0%, and the oxidation rate of zinc is 90%. The main metal minerals in this ore sample are smithsonite, willemite, hemimorphite, limonite, white leadite, sphalerite, galena, etc. The gangue minerals are mainly quartz, dolomite, calcite, clay, etc. Minerals, sericite, kaolin, etc. Gangue minerals mica and clay minerals have better floatability, which will increase the amount of flotation reagents and reduce the grade of zinc concentrate during the flotation process. The closed circuit test results of Example 2 are shown in Table 1.

[0067] The specific process is as follows:

[0068] ⑴ Desilting flotation:

[0069] The lead-zinc sulfide flotation tailings are used as raw ore, and the amount of sludge collector (a) is 50g / t based on the dry ore weight of the raw ore. mud, respectively, to obtain mud-containing slurry and deslimed tailings slurry (for zinc oxide flotation).

[0070] Among t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com