A kind of amphiphilic polymer containing capped polyether structure and its preparation and application

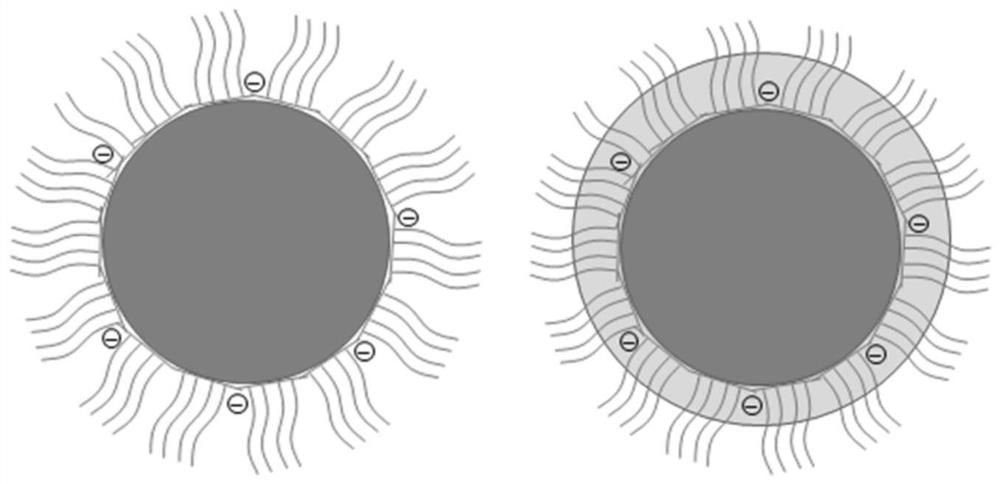

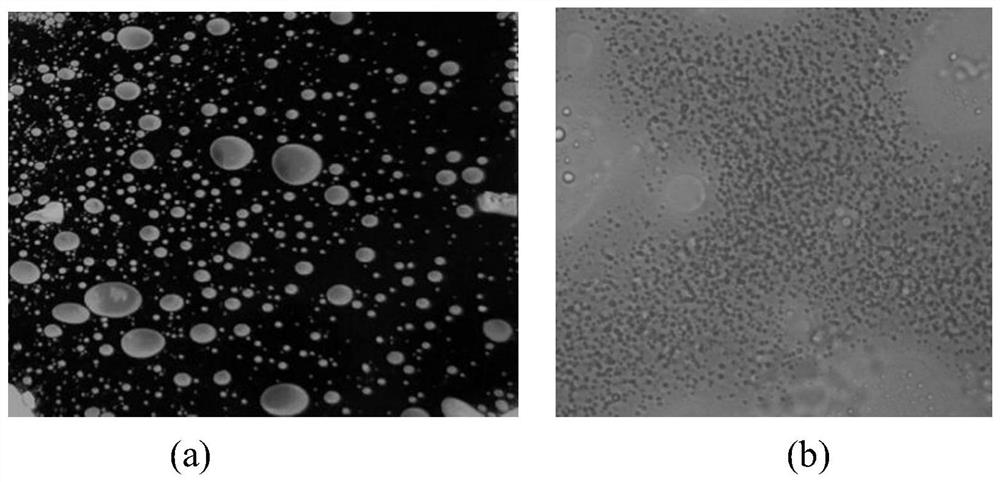

An amphiphilic polymer and end-capped polyether technology, which is applied in the petrochemical field, can solve the problems of decreased application performance of oil displacing agent, unsatisfactory oil displacing effect, etc. The effect of long-term stable coalescence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

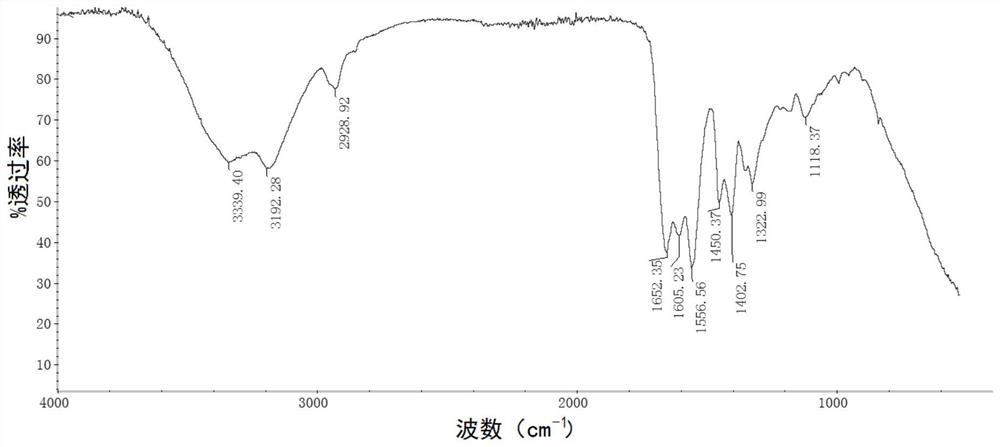

Embodiment 1

[0035] This embodiment provides an amphiphilic polymer containing a capped polyether structure, which is prepared through the following steps:

[0036] Weigh 37.4g of monomer A (acrylamide), 0.85g of benzenesulfonate monomer B (R 2 is H, m=10), 2.9g end-capped polyether monomer C (R 3 for H, R 4 for CH 3 , n is 58) in a dissolver, add 138.1g of deionized water and stir to dissolve, then add 5.39g of sodium carbonate and stir to dissolve, adjust the temperature to 13°C, transfer the solution to the reactor, add 3.8g of ethylenediaminetetraacetic acid Disodium solution (concentration is 3.0%), 1.69g sodium formate solution (concentration is 6%), 6.34g sodium bisulfite solution (concentration is 1.5%) and other polymerization aids, feed nitrogen after 30min, add 5.39g persulfuric acid Potassium solution (concentration is 0.7%), 3.2g of 2,2-azobisisobutylamidine dihydrochloride solution (concentration is 0.25%), seal reactor after continuing to pass nitrogen for 10min, after 4h...

Embodiment 2

[0039] This embodiment provides an amphiphilic polymer containing a capped polyether structure, the preparation steps are the same as in Example 1, and the type and amount of raw materials are: 36.2g monomer A (R 1 for NH 2 , ie acrylamide), 1.3g benzenesulfonate monomer B (R 2 for CH 3 , m=12), 4.6g capped polyether monomer C (R 3 for H, R 4 for CH 3 , n is 46), 136g deionized water, 3.9g sodium carbonate, 0.37g sodium lauryl sulfate, 4.22g edetate disodium solution (concentration is 3.0%), 2.35g sodium hypophosphite solution (concentration 6%), 6.3g sodium bisulfite solution (concentration is 1.5%), 5.9g potassium persulfate solution (concentration is 0.7%), 3.9g of 2,2-azobisisobutylamidine dihydrochloride solution (0.25% concentration). The obtained polymer gel was taken out, and after granulation, drying, crushing and sieving, an amphiphilic polymer containing a capped polyether structure was obtained, and the molecular weight of the finally obtained polymer was 9.6...

Embodiment 3

[0041] This example provides an amphiphilic polymer containing a capped polyether structure, using sodium acrylate instead of acrylamide and sodium carbonate, and other steps are the same as in Example 1. The raw material formula is as follows: 28.5g monomer A (R 1 is ONa, i.e. sodium acrylate), 2.2g benzenesulfonate monomer B (R 2 Is H, m=11), 6.2g capped polyether monomer C (R 3 for H, R 4 for C 6 h 6 , n is 38), 135.2g deionized water, 0.97g sodium lauryl sulfate, 4.26g disodium edetate solution (concentration is 3.0%), 2.8g sodium formate solution (concentration is 6%), 7.5 g sodium bisulfite solution (concentration is 1.5%), 6.2 g potassium persulfate solution (concentration is 0.7%), 3.3 g of 2,2-azobisisobutylamidine dihydrochloride solution (concentration is 0.25%) ). The obtained polymer gel is taken out, and after granulation, drying, crushing and sieving, an amphiphilic polymer containing a capped polyether structure can be obtained, and the molecular weight o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com