Modified organic polysilazane based on long-chain alkyl compound modification, preparation method and application thereof

A long-chain alkyl, polysilazane technology, applied in the direction of coating, can solve the problems of poor bonding force and poor durability, and achieve the effects of low cost, good scalability and strong designability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Example 1 Preparation of modified organopolysilazane based on long-chain alkyl compound modification

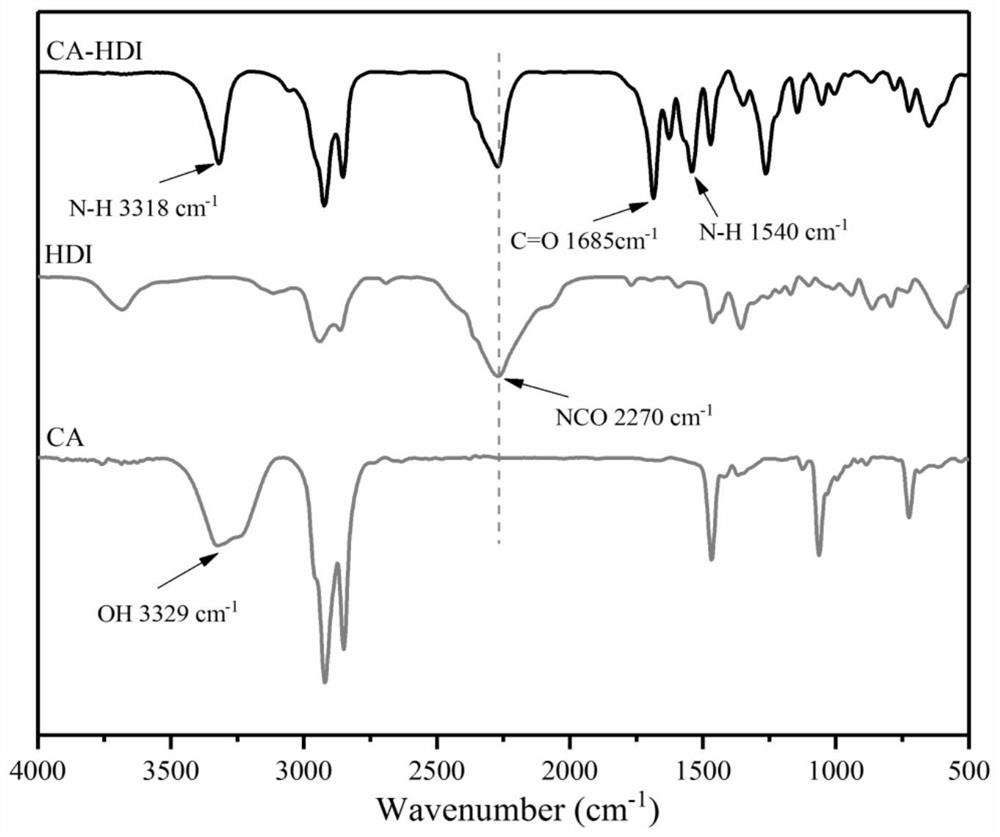

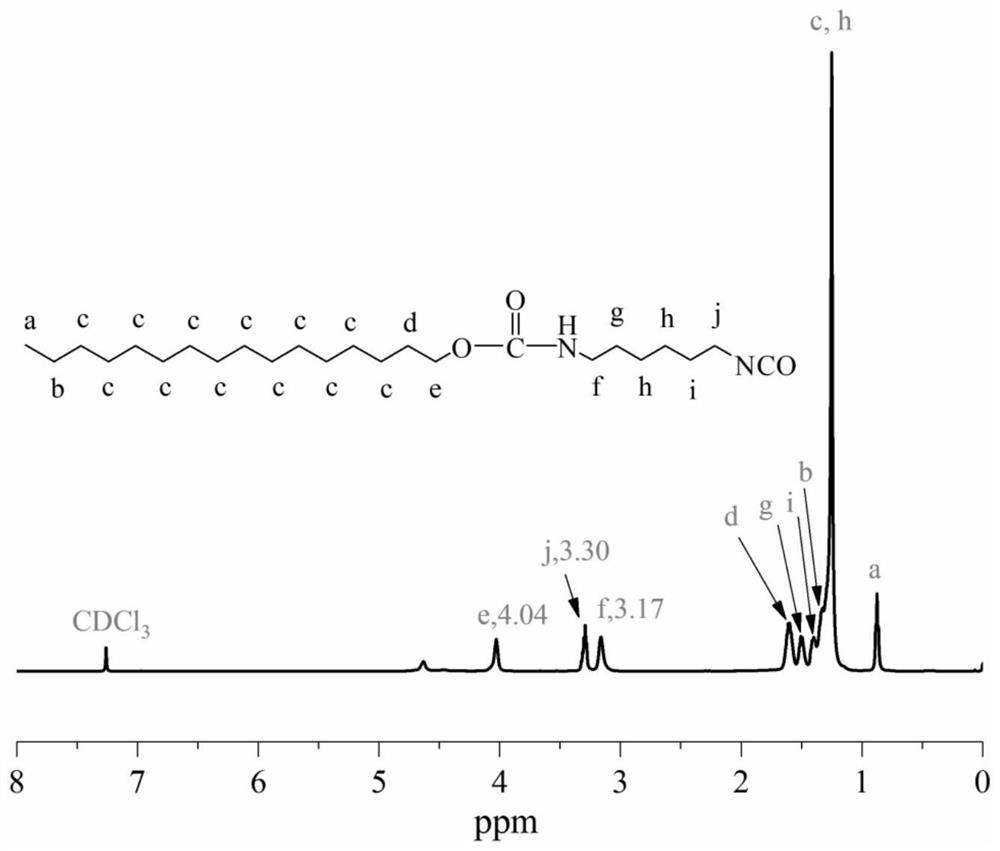

[0068] (1) Synthesis of long-chain alkyl compounds: under the protection of argon, 0.665g of n-hexadecyl alcohol (CA) and 0.500g of hexamethylene diisocyanate (HDI) were added to 10ml of tetrahydrofuran solvent, and mixed uniformly; Then, add triethylamine accounting for 0.10wt% of the total mass of reactant monomers, and react for 5 hours at a temperature of 50°C to obtain a long-chain alkyl compound solution. The product is denoted as CA-HDI, and its chemical structure is as follows shown.

[0069]

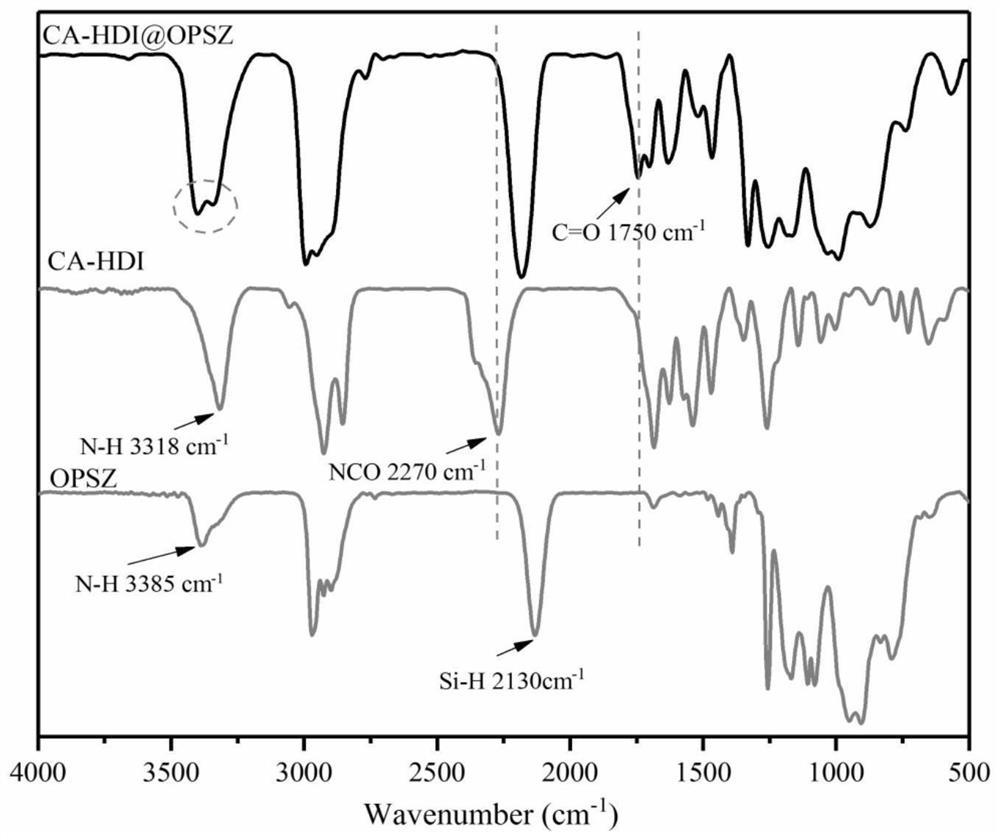

[0070] (2) Preparation of modified organopolysilazane based on long-chain alkyl compound modification: under argon protection, 11.65g of organopolysilazane OPSZ was added to the CA-HDI solution prepared in step (1) , stirring evenly; at a temperature of 25° C., after 7 hours of reaction, the solvent in the reaction system was removed to obtain a modified organopolysi...

Embodiment 2

[0078] Example 2 Preparation of modified organopolysilazane based on long-chain alkyl compound modification

[0079] (1) Synthesis of long-chain alkyl compounds: under argon protection, 1.110g of n-dodecyl alcohol (DA) and 1.000g of hexamethylene diisocyanate (HDI) were added to 15ml of tetrahydrofuran solvent, and mixed uniformly; Then, add 0.05wt% dibutyltin dilaurate accounting for the total mass of reactant monomers, and react for 5.5 hours at a temperature of 55°C to obtain a long-chain alkyl compound solution, and the product is marked as DA-HDI.

[0080] (2) Preparation of modified organopolysilazane based on long-chain alkyl compound modification: under the protection of argon, 25.32g of organopolysilazane was added to the DA-HDI solution obtained in step (1), and stirred Uniform; after reacting for 3.5 hours at a temperature of 45°C, remove the solvent in the reaction system to obtain the modified organopolysilazane M-OPSZ modified with long-chain alkyl compounds. In...

Embodiment 3

[0083] Example 3 Preparation of modified organopolysilazane based on long-chain alkyl compound modification

[0084] (1) Synthesis of long-chain alkyl compounds: under nitrogen protection, 1.381g of 7-phenyl-1-heptanol (PHA) and 1.500g of trimethylhexamethylene diisocyanate (TDMI) were added to 20ml of dioxane In the solvent, mix evenly; Then, add tetramethylbutylene diamine accounting for 0.03wt% of the total mass of reactant monomers, and react for 5.0 hours at a temperature of 60°C to obtain a long-chain alkyl compound solution. The product is described as for PHA-TDMI.

[0085] (2) Preparation of modified organopolysilazane based on long-chain alkyl compound modification: under nitrogen protection, 23.50 g of organopolysilazane was added to the PHA-TDMI solution obtained in step (1), and stirred evenly ; After reacting for 5.0 hours at a temperature of 35°C, remove the solvent in the reaction system to obtain the modified organopolysilazane M-OPSZ modified with long-chain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com