Patents

Literature

32 results about "Zirconium disulfide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zirconium(IV) sulfide is the inorganic compound with the formula ZrS₂. It is a violet-brown solid. It adopts a layered structure similar to that of cadmium iodide. Like the closely related titanium disulfide, ZrS₂ is prepared by heating sulfur and zirconium metal. It can be purified by vapor transport using iodine.

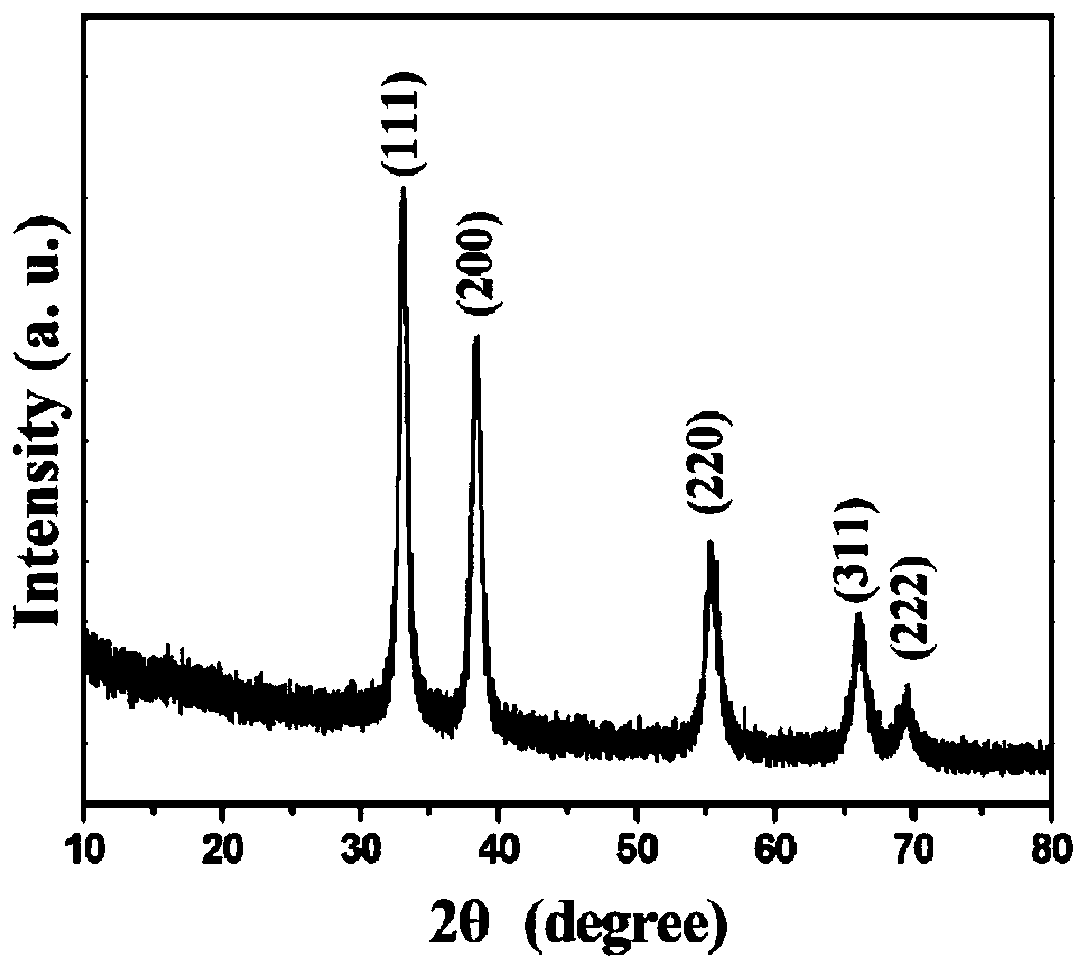

Preparation method of zirconium dioxide powder

The invention relates to a preparation method of zirconium dioxide powder, comprising the following steps: A. dissolving zirconium oxychloride into deionized water, and controlling mass ratio of the zirconium oxychloride and the deionized water to be 4:(21-35); B. dropwise adding ammonia water into mixed solution in the step A, and controlling mole ratio of the ammonia water and the zirconium oxychloride to be (1.8-3.7):1; C. carrying out washing, pressing and filtering or centrifugal separation on zirconium hydroxide hydrogel in the step B to obtain zirconium hydroxide gel; D. drying the zirconium hydroxide gel of the step C to obtain zirconium hydroxide, and calcining the zirconium hydroxide to obtain zirconium dioxide; E. mixing the zirconium dioxide in the step D with grinding medium and water and carrying out wet grinding on the mixture; and F. drying the zirconium dioxide slurry in the step E to prepare the zirconium dioxide powder. The zirconium dioxide powder product produced by the method has good particle monodispersity, complete particle form, concentrating distribution of particle size, high purity and controllable particle size and can realize low cost when in large-scale production of the zirconium dioxide.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

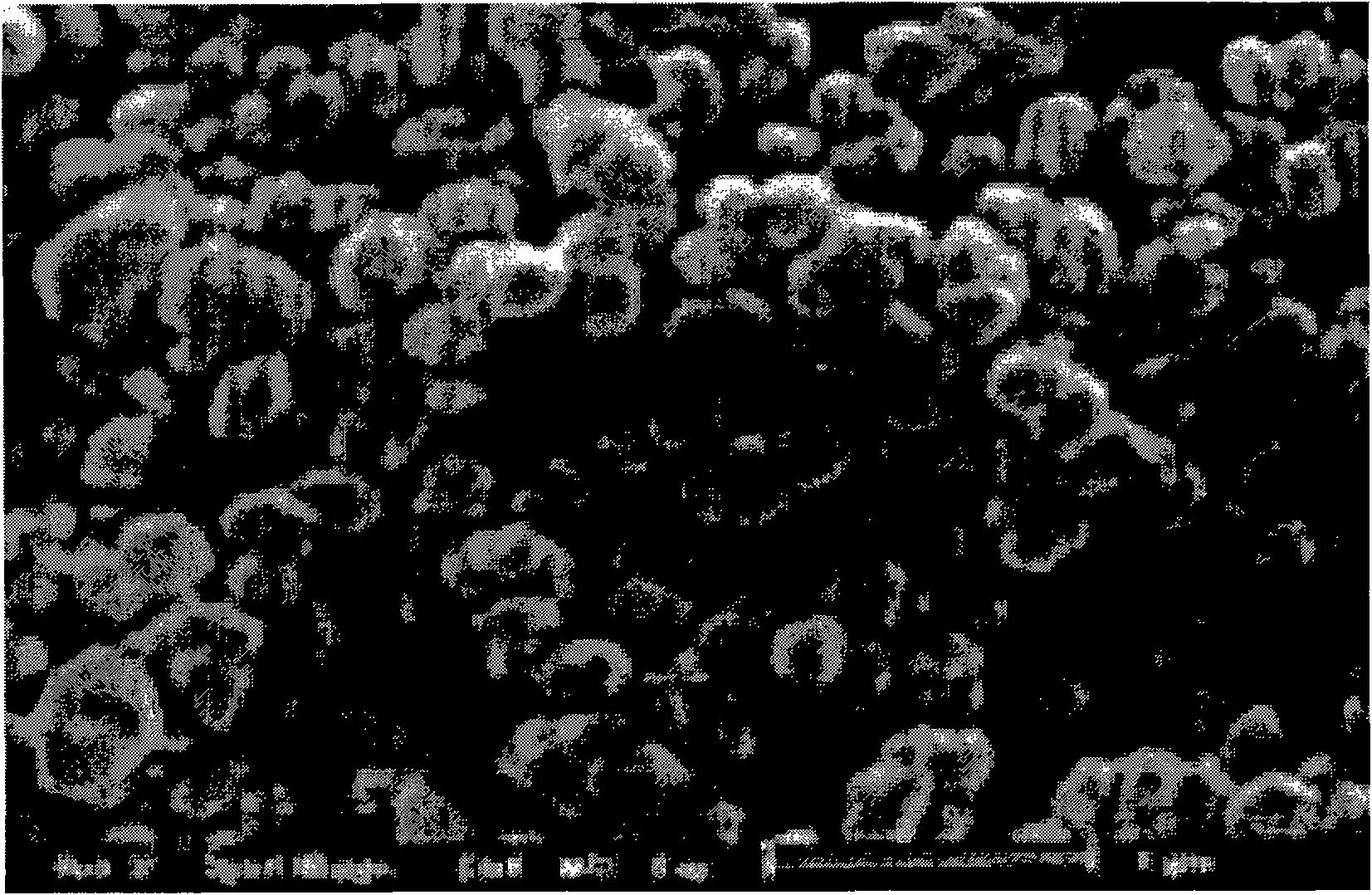

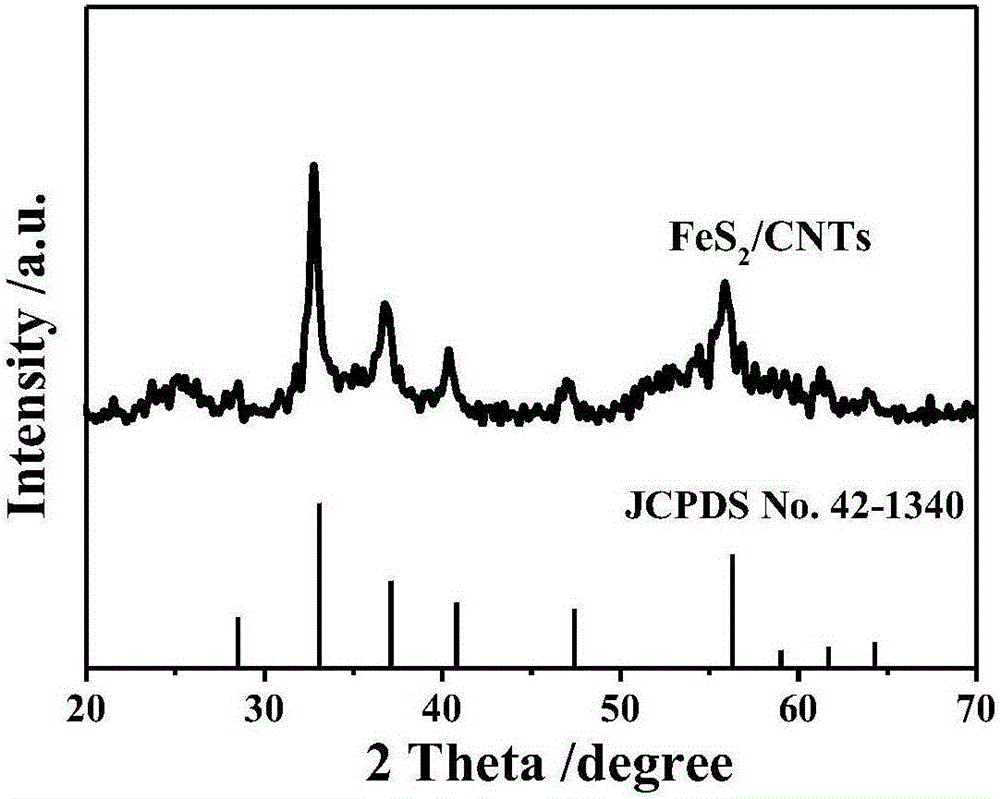

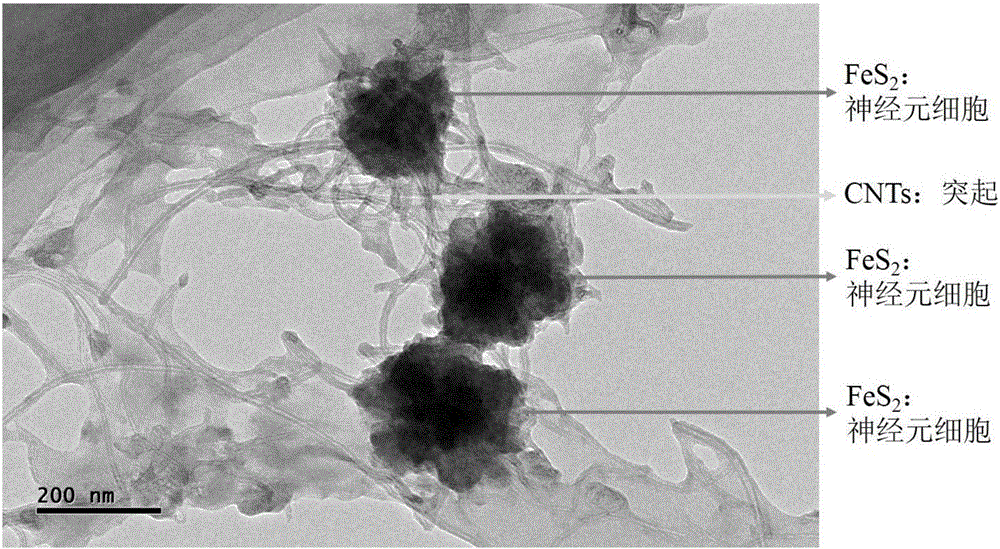

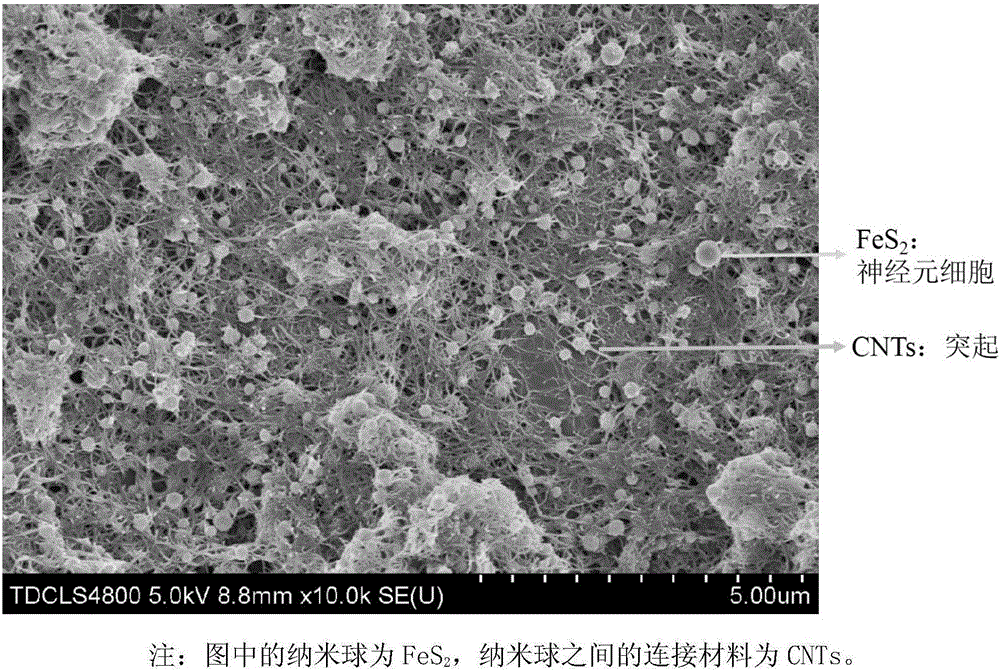

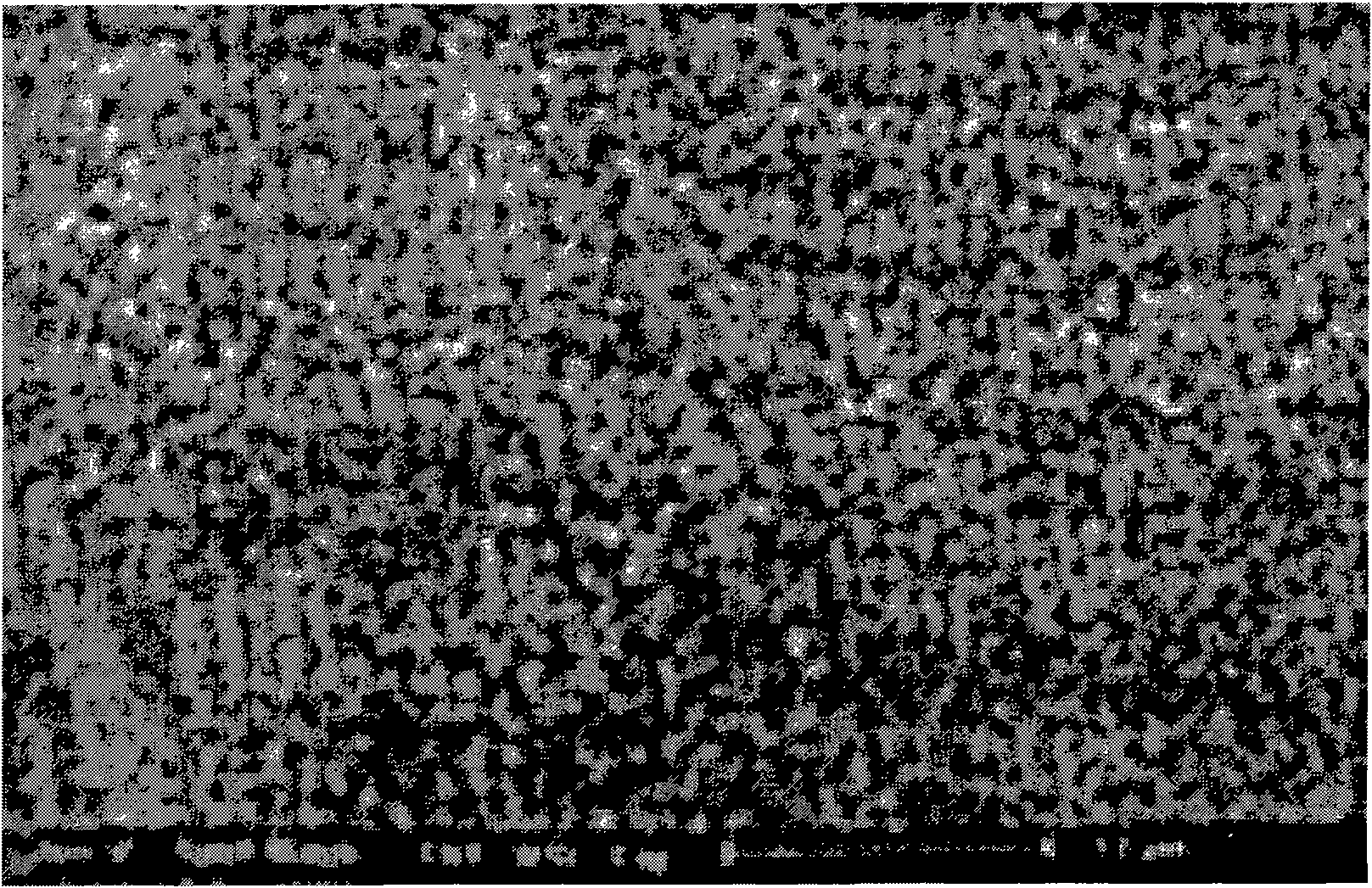

Iron disulfide/carbon nano tube composite material of neural network structure and preparation method thereof

InactiveCN106848230AImprove cycle performanceImprove conductivityCell electrodesSecondary cellsIron(III) sulfideCarbon nanotube

The invention provides an iron disulfide / carbon nano tube composite material of a neural network structure and a preparation method thereof. The preparation method comprises the following steps of adding a carbon nano tube into mixed liquor of ethylene glycol and N,N'-dimethylformamide, and carrying out ultrasonic treatment to obtain carbon nano tube uniformly dispersed mixed liquor; adding ferrous sulfate, sublimed sulfur and urea into the mixed liquor, sufficiently agitating an obtained mixture, and then transferring the mixture into a hydrothermal reaction kettle to carry out a reaction; centrifugally separating a deposit, washing the deposit by using deionized water and alcohol, and then carrying out vacuum drying to obtain the iron disulfide / carbon nano tube composite material which is of the neural network structure. The iron disulfide / carbon nano tube composite material is of a three-dimensional neural network structure which is formed by mutually connecting neurons for which an iron disulfide particle is used as a neuron cell and the carbon nano tube is used as a prominence, wherein the diameter of the iron disulfide particle is not more than 200nm. The neural network structure can be used for improving the electric conductivity of a material; meanwhile, the volume expansion of iron disulfide in charging and discharging processes is buffered through the mechanical property of the carbon nano tube; besides, the wettability of an electrolyte on the material can be also improved through the three-dimensional structure of a neutral network and the nano size of the iron disulfide; the cyclical stability of an iron disulfide material as a sodium-ion negative electrode is greatly improved.

Owner:TIANJIN UNIV

Ceramic slurry and preparation method of zirconium oxide-based composite ceramic

InactiveCN107673758AHigh speedGood effectAdditive manufacturing apparatusComposite ceramicRare earth

The invention belongs to the technical field of 3D (Three Dimensional) printing and in particular relates to ceramic slurry and a preparation method of zirconium dioxide-based composite ceramic. The ceramic slurry provided by the invention is prepared from the following components: 30 to 90 parts of zirconium oxide-based composite powder, 10 to 70 parts of light-cured resin and 0.1 to 5 parts of aphotoinitiator, wherein the zirconium oxide-based composite powder is prepared from the following raw materials: 3Y-TZP powder and rare earth oxide powder; rare earth oxide comprises one or more of Cr2O3, Er2O3, Co3O4, Fe2O3, Pr6O11 and MnO2. By controlling the types and adding amounts of the rare earth oxide in the zirconium oxide-based composite powder, obtained zirconium oxide-based compositeceramic has a uniform pink, red, blue, green or yellow color from a single zirconium white color and can be applied to preparation of zirconium dioxide ceramic with various colors, so that the increasing individualized requirements of people are met.

Owner:GUANGDONG UNIV OF TECH

Glass inner container for the electric cooker and the processing technics thereof

InactiveCN101112295ABeautiful appearanceEasy to cleanCooking-vessel materialsDissolutionSilicon dioxide

The invention discloses a glass inner container for the electric cooker which is made of silica dioxide, aluminum oxide, zirconium dioxide and boric oxide, wherein the silica dioxide is the basic raw material, the weight percentage of the raw material is that the silica dioxide is of 70-80%, the aluminum oxide is of 1-3%, the zirconium dioxide is of 3-8% and the boric oxide is of 10-20%. The producing method of the glass inner container for the electric cooker is that A: the raw material is prepared proportionally; B: the prepared raw material is mixed evenly by a mixing machine; C: the raw material which is mixed evenly is sent into the dissolution pool and is heated to the temperature of 1400-1600 DEG C, thus forming glass liquid; D: the glass liquid is sent into the working pool to carry out depositing and filtering disposal; E: the glass liquid is sent to the formed press mold and is produced into an end product. The glass inner container produced by the adopted art is thermostable, beautiful in appearance, convenient in cleaning, and the glass product meets the demand of the human and the current society for different aspect of the product such as health, environment protection and so on.

Owner:湖北九龙泰环保科技有限公司

Preparation method of zirconium diboride (ZrB2) ceramic precursor

InactiveCN107814577AHigh ceramic conversion rateMeet the requirements of PIP processZirconium disulfideAcetylacetone

The invention relates to the technical field of material chemistry, in particular to a method for preparing a zirconium boride ceramic precursor. A preparation method of zirconium diboride ceramic precursor adopts the following steps: step 1: raw material; step 2: synthesis of zirconium-containing polymer PZS; step 3: preparation of ZrB2 ceramic precursor. In the present invention, zirconium oxychloride, acetylacetone and o-hydroxybenzyl alcohol undergo polycondensation reaction under alkaline conditions to generate a zirconium-containing polymer, and the polymer is blended with boric acid in a solution to obtain a ZrB2 ceramic precursor. The ceramic precursor prepared by this method can form a homogeneous impregnation solution, has a high ceramic conversion rate, meets the requirements of the PIP process, and has broad application prospects in the construction of ZrB2 ceramic modified C / C composites.

Owner:SHAANXI SHENGMAI PETROLEUM

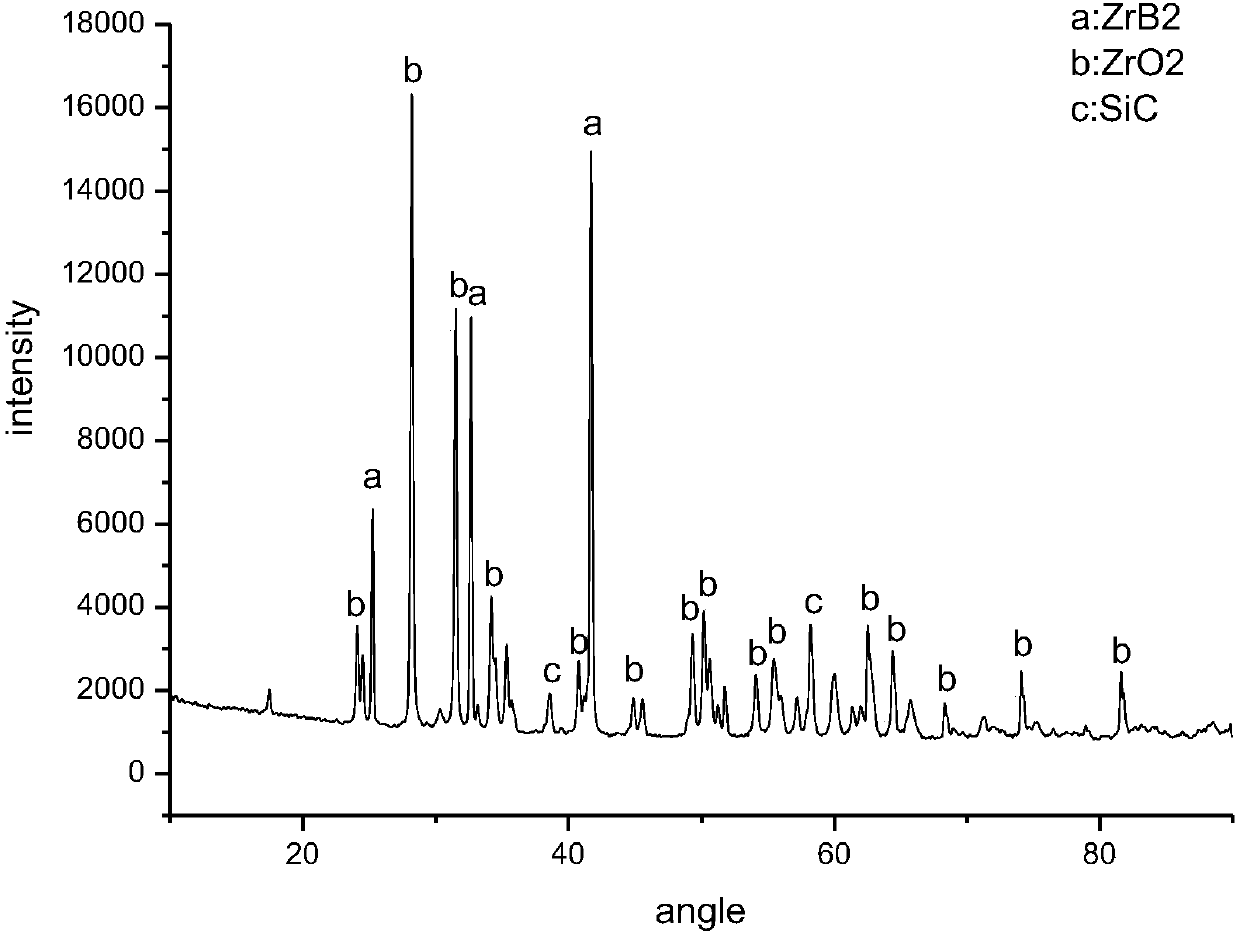

Method for performing oxide in-situ coating on zirconium diboride-silicon carbide aggregate powder

The invention relates to a method for performing oxide in-situ coating on zirconium diboride-silicon carbide aggregate powder, belonging to the technical field of composite powder materials. The method comprises the following steps: carrying out in-situ coating on zirconium diboride-silicon carbide aggregate powder by utilizing oxides produced by self-oxidation of the zirconium diboride-silicon carbide aggregate powder in a high-temperature oxidation environment, and preparing composite powder with a core-shell structure. The oxide coated zirconium diboride-silicon carbide with the core-shellstructure prepared by the method has high degree of sphericity and density, and the requirement of plasma spraying on the powder is met; the oxide coating layer produced by self-oxidation can inhibitvolatilization of silicon carbide in the plasma spraying process, and loss of the silicon carbide is reduced. Moreover, the melting point of the oxide is lower than that of the zirconium boride, the powder can be fully molten, gaps, vacancy and other defects caused by lamella overlap in the coating are further filled, and the density of the coating is improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

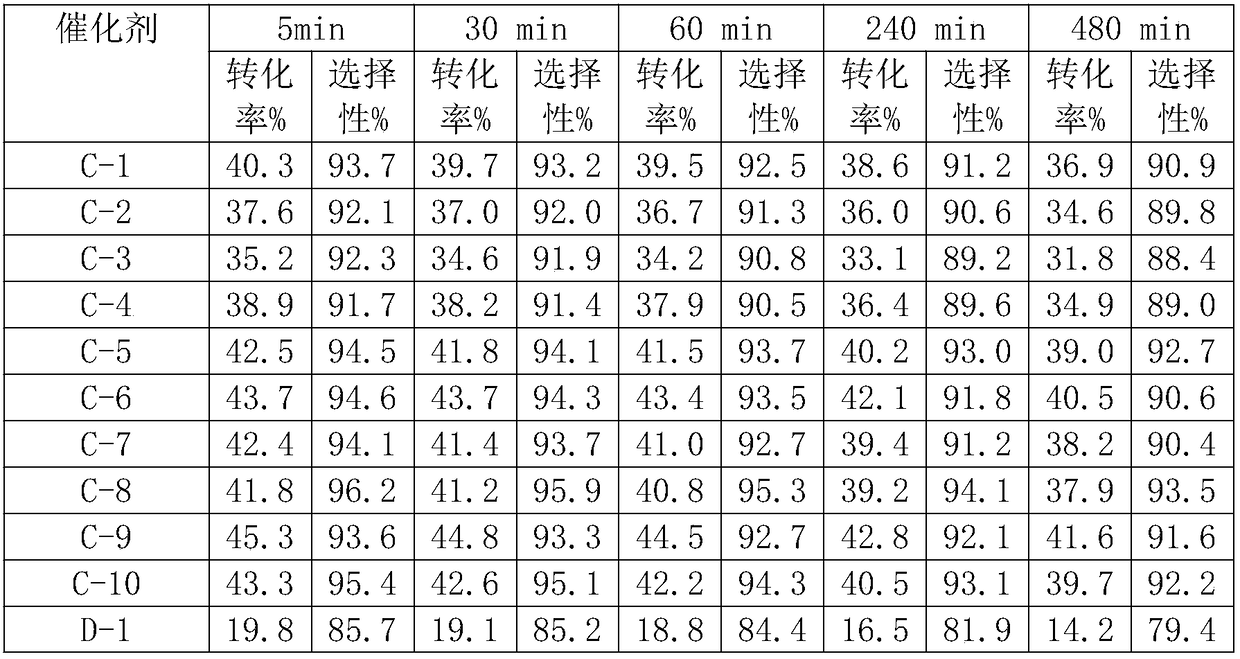

Dehydrogenation catalyst and preparation method thereof

ActiveCN108579742AHigh activityImprove stabilityCatalyst activation/preparationHydrocarbonsCooking & bakingPotassium

The invention belongs to the technical field of a catalyst, and discloses a dehydrogenation catalyst and a preparation method thereof. A composite oxide formed by zinc modified zirconium dioxide and active aluminum oxide is used as a carrier; Pt is used as a major active ingredient; ingredients selected from one or several elements from potassium, magnesium, tin, lanthanum, cerium, ferrum, cobaltand nickel are used as auxiliary active ingredients; Pt nano particle sol is used as steeping liquid for steeping the composite oxide carrier formed by zinc modified zirconium dioxide and active aluminum oxide; the steeped composite oxide carrier formed by zinc modified zirconium dioxide and active aluminum oxide is subjected to drying, baking and reduction to obtain the dehydrogenation catalyst;the aggregation of Pt at high temperature can be obviously reduced; Pt is uniformly distributed in the composite oxide carrier; the active ingredient Pt has large specific surface; the dehydrogenationcatalyst is applied to reaction of preparing propylene through propane dehydrogenation; high propylene selectivity is maintained; meanwhile, the propane conversion rate is obviously improved; the high-temperature stability of the catalyst is also obviously improved.

Owner:四川知汇通科技有限公司

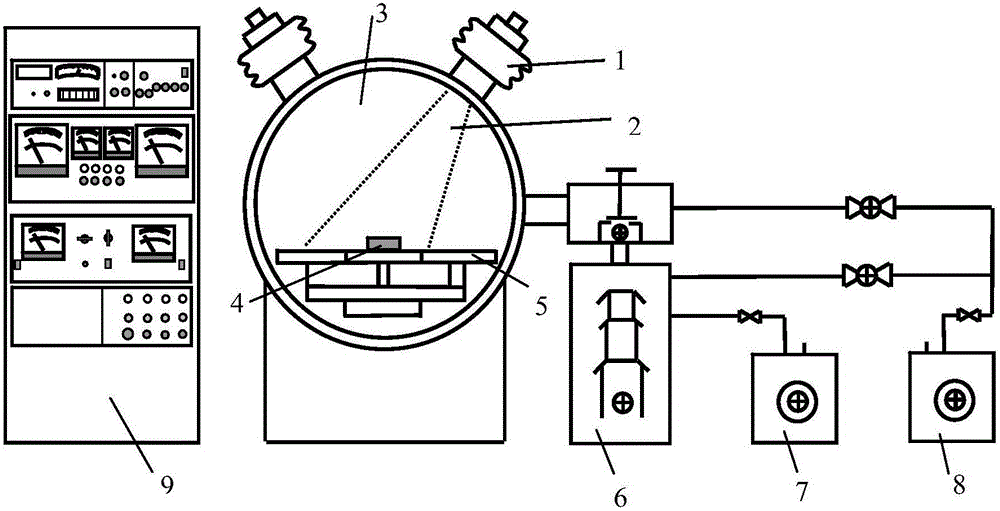

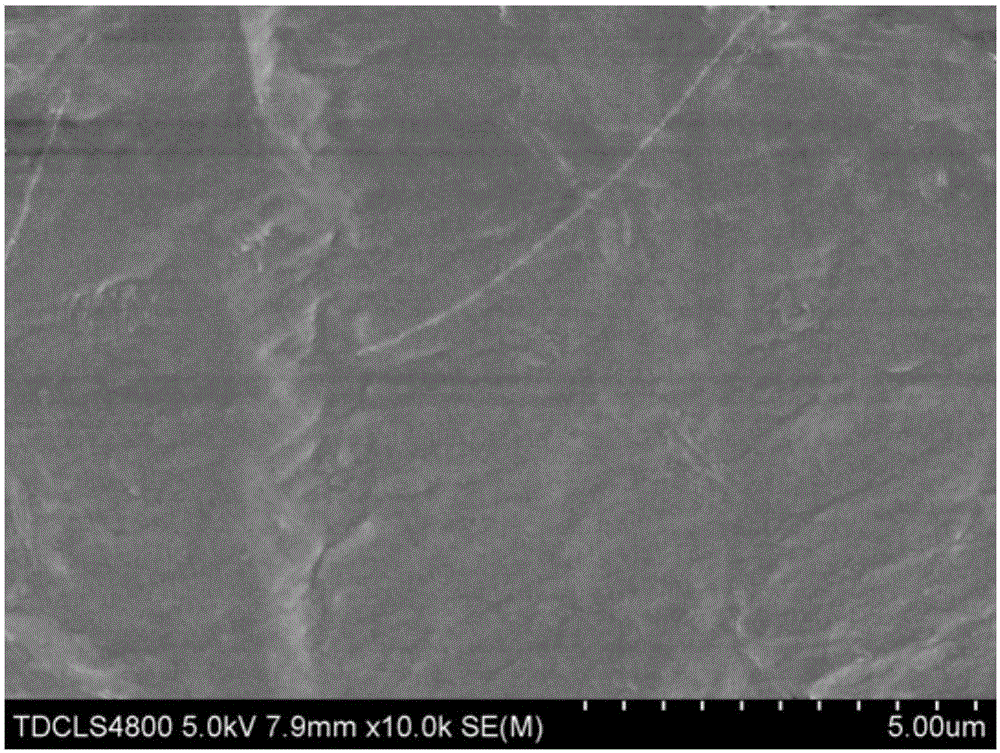

Large-area zirconium disulfide film and atomic layer deposition preparation method thereof

InactiveCN110551988APrecise and controllable atomic thicknessHas a large areaChemical vapor deposition coatingChemical reactionSulfur

The invention discloses a large-area zirconium disulfide film and an atomic layer deposition preparation method thereof. A zirconium precursor and a sulfur precursor are alternatively introduced intoa reaction cavity, and self-limitation chemical reaction is generated on a substrate surface to grow the large-area zirconium disulfide film. The preparation process comprises 10-5000 growth cycles, and each growth cycle comprises four steps: 1) introducing the zirconium precursor into the reaction cavity of an atomic layer deposition system through pules, and adsorbing the zirconium precursor onto the substrate surface; 2) introducing high-purity nitrogen gas into the reaction cavity of the atomic layer deposition system through pulses to clean excessive zirconium precursor and reaction byproducts; 3) introducing the sulfur precursor into the reaction cavity of the atomic layer deposition system through pulses, and enabling the sulfur precursor and the zirconium precursor adsorbed to thesubstrate surface to generate self-limitation chemical reaction to generate a zirconium disulfide atomic layer; and 4) introducing high-purity nitrogen gas into the reaction cavity of the atomic layerdeposition system through pulses to clean excessive zirconium precursor and reaction byproducts. The large-area zirconium disulfide film has the advantages of being precisely controllable in atomic-level thickness, great in area, uniform, and the like.

Owner:ANYANG NORMAL UNIV

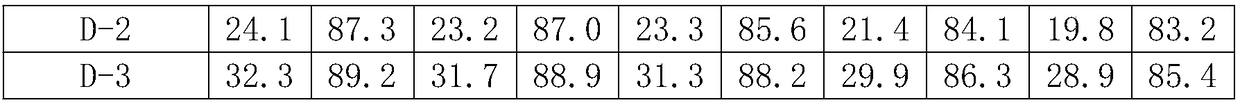

Tubular titanium dioxide nano composite Sb adsorbent loaded with zirconium dioxide and ferroferric oxide and preparation method and application thereof

ActiveCN109621883AEasy magnetic separationEasy to separateOther chemical processesWater contaminantsChlorideTithonia tubiformis

The invention discloses a tubular titanium dioxide nano composite Sb adsorbent loaded with zirconium dioxide and ferroferric oxide and a preparation method and application thereof. the preparation method comprises the following steps of: (1) preparing a nano titanium dioxide pipe from TiO2 nano particles by using an alkaline hydrothermal method; (2) preparing zirconium chloride stock solution andstock solution containing ferric chloride and ferrous chloride respectively; (3) loading ZrO2 and Fe3O4 on the nano titanium dioxide tube to prepare the ZrO2 and Fe3O4 loaded tubular TiO2 nano composite Sb adsorbent, which is marked as ZrO2@Fe3O4@TiO2NTs. The adsorbent can adsorb Sb (III) and Sb (V) in a water body at the same time, the adsorbent with unit mass has high Sb adsorption efficiency, the separation of the adsorbent and the water body can be simply achieved under the action of a magnetic field, and the recovery efficiency of the adsorbent is high.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Production process of ferrous disulfide

The invention provides a production process of ferrous disulfide, and belongs to chemurgy. The following raw materials including sodium disulfide, ammonium disulfide, potassium disulfide, ferrous sulfate, ferrous ammonium sulfate and ferrous chloride are required in a synthesis process. The sodium disulfide, the ammonium disulfide, the potassium disulfide, the ferrous sulfate, the ferrous ammonium sulfate and the ferrous chloride are respectively dissolved into water at the normal temperature of 25 DEG C to be made into a saturated solution; the sodium disulfide, the ammonium disulfide and the potassium disulfide can be sequentially matched with the ferrous sulfate, the ferrous ammonium sulfate and the ferrous chloride, and can also be respectively combined and matched to obtain a ferrous disulfide suspension solution. Vacuum suction filtration, drying and drying are performed, and then, crushing is performed to obtain ferrous disulfide powder. The synthesized ferrous disulfide suspension solution and the ferrous disulfide powder have wide purposes on agriculture; good market prospects are realized; a promotion effect is achieved on promoting the agriculture modernization construction in China; certain economic benefits and social benefits can be achieved on agricultural means of production enterprises and the society.

Owner:刘长福

Preparation method for ZrS2 two-dimensional semi-conducting material

InactiveCN105836798AImprove flatnessImprove performanceZirconium compoundsSemiconductor materialsGas phase

The invention discloses a preparation method for a ZrS2 two-dimensional semi-conducting material. The preparation method comprises the following steps: step a, obliquely placing two SiO2 / Si substrates on a quartz boat A, then placing the quartz boat A and the SiO2 / Si substrates into a high-temperature tubular furnace and putting the quartz boat A at the central position of a quartz tube of the high-temperature tubular furnace; step b, spreading zirconium chloride powder in a quartz boat B and putting the quartz boat B in the quartz tube of the high-temperature tubular furnace at a position 12 to 15 cm away from the quartz boat A; step c, putting sulfur boat at a position 12 to 15 cm away from the quartz boat A, wherein the sulfur boat and the quartz boat B are both located at one side of the quartz boat A; and step d, introducing inert gas into the quartz tube at normal temperature for 8 to 15 min to totally evacuate air in the quartz tube, then turning down the flow of the inert gas, heating the high-temperature tubular furnace to 770 to 880 DEG C and then carrying out natural cooling after complete reaction. Thus, the method provided by the invention can prepare the high-quality two-dimensional ZrS2 material by using a normal-pressure physical vapor deposition method.

Owner:GUANGDONG UNIV OF TECH

Method of preparing zirconium carbide nanomaterial with waste plastics

InactiveCN109824051AWide range of sources and cheapSimple production equipmentMaterial nanotechnologyCarbon compoundsMetallic lithiumZirconium hydride

The invention belongs to the technical field of zirconium carbide nanomaterials and particularly relates to a method of preparing a zirconium carbide nanomaterial with waste plastics. The method comprises the steps of (1) adding zirconium dioxide, waste plastics and metallic lithium into a reactor in a mass ratio of 1:(0.2-1):(2-10); (2) heating the reactor to allow chemical reaction to occur, andcooling after the reaction is over; (3) washing the product, and drying to obtain the zirconium carbide nanomaterial. The waste plastics are used as carbon sources herein; the material origin range is wide; the materials are low in price; conversion of the waste plastics to the zirconium carbide nanomaterial can be achieved herein through one-step chemical reaction; the environmental pollution problem due to waste plastics is solved.

Owner:JIANGSU UNIV OF TECH

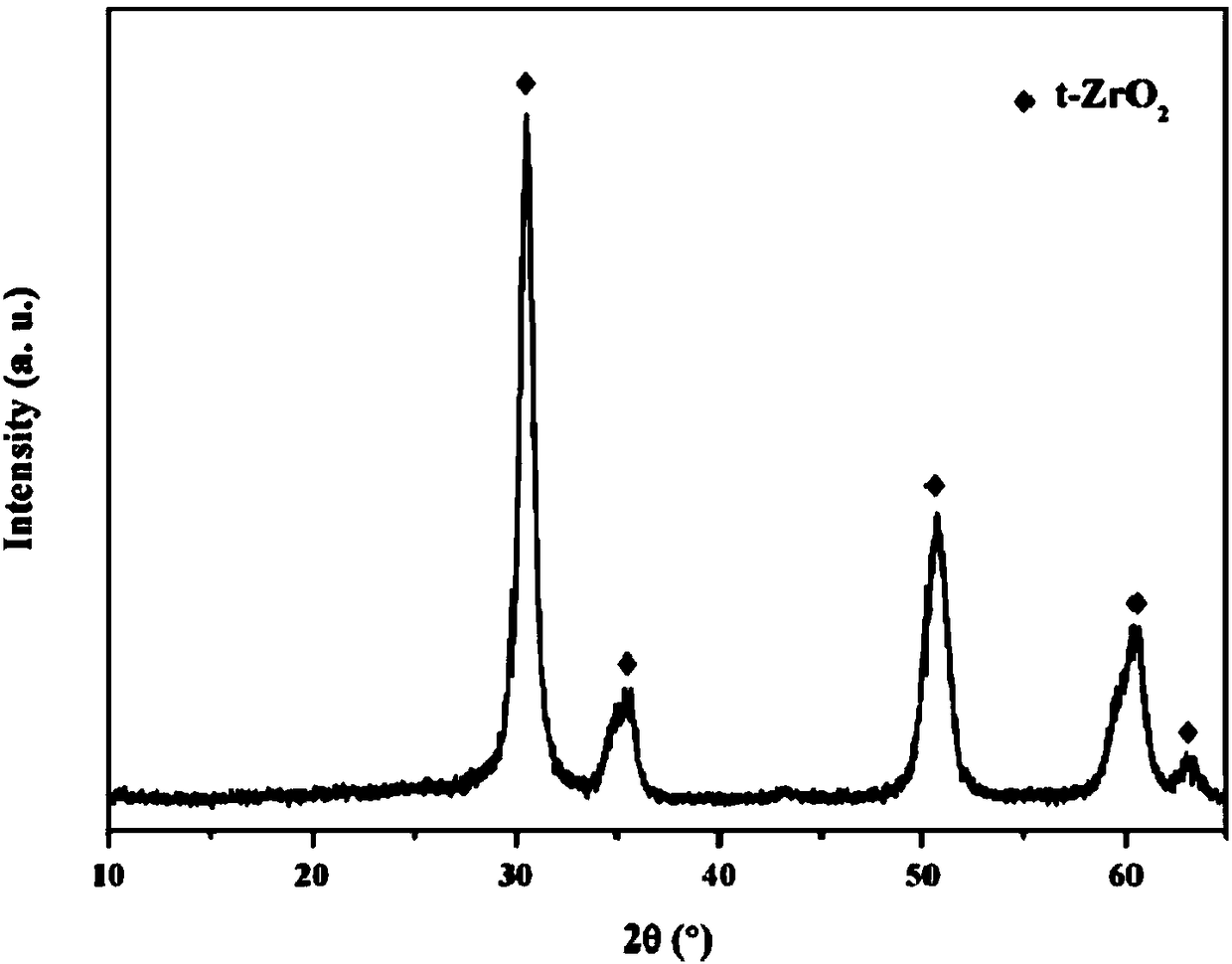

Method for preparing zirconium oxide powder by hydrothermal method using solid waste zirconium as raw material

InactiveCN108059186AHigh purityIncrease contentNanotechnologyZirconium oxidesMaterials preparationSulfate

Owner:SHANDONG LEIBAO ZIRCONIUM SCI&TECH

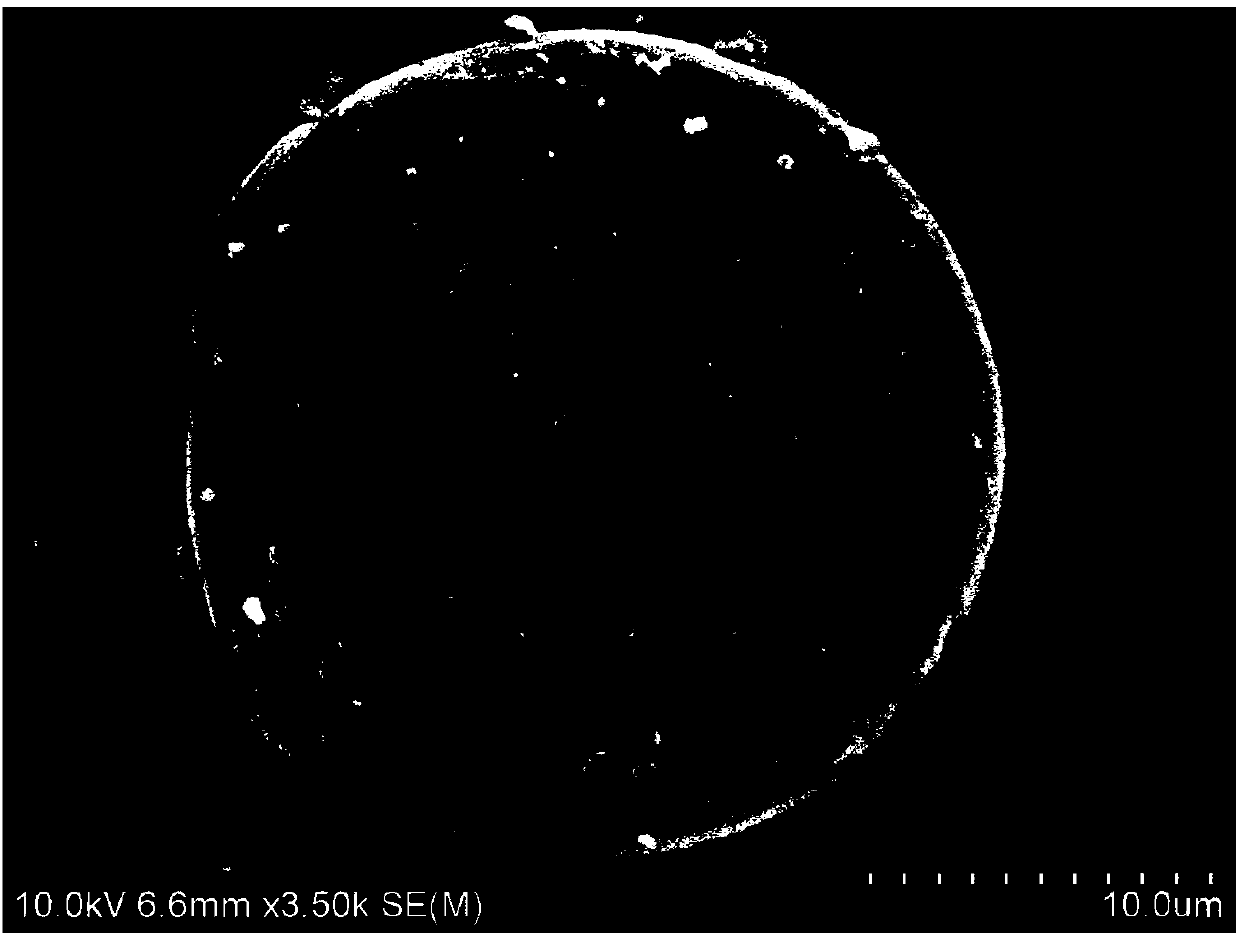

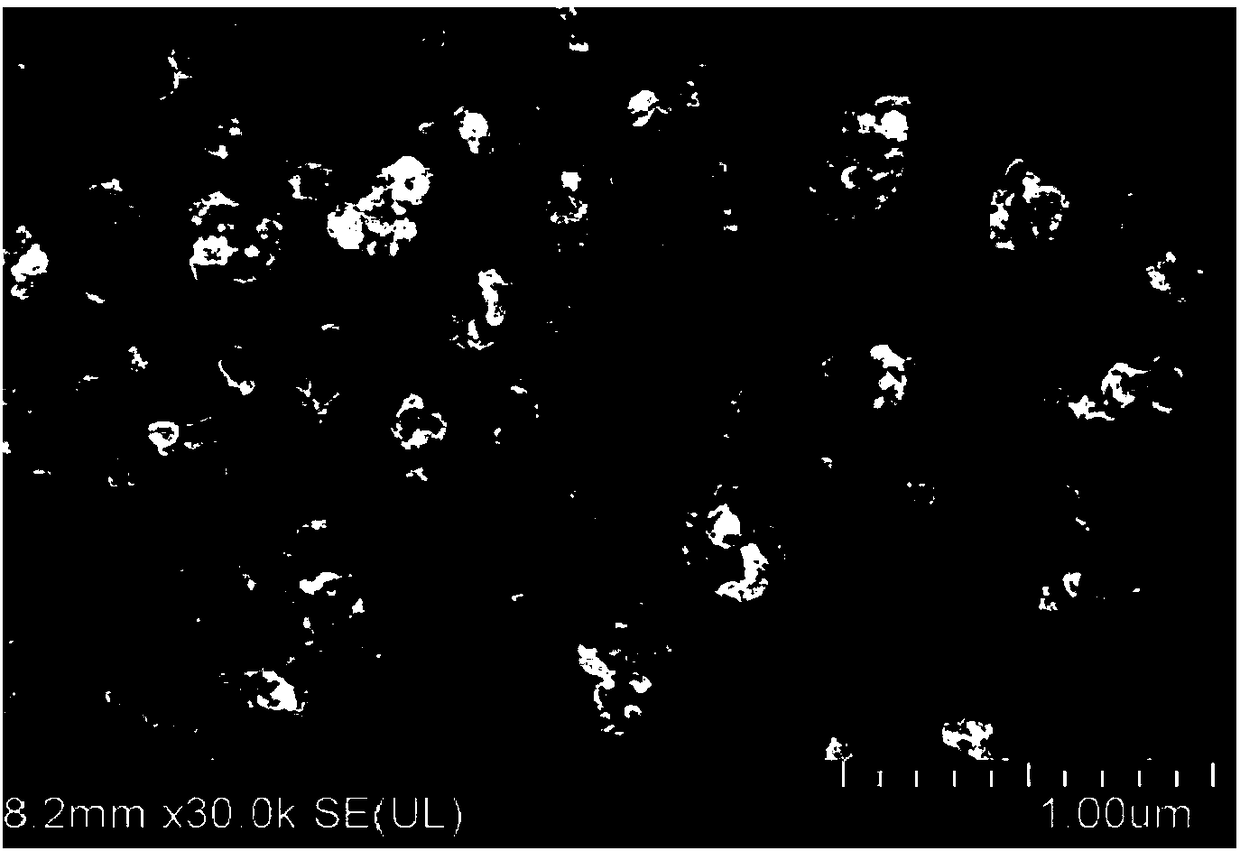

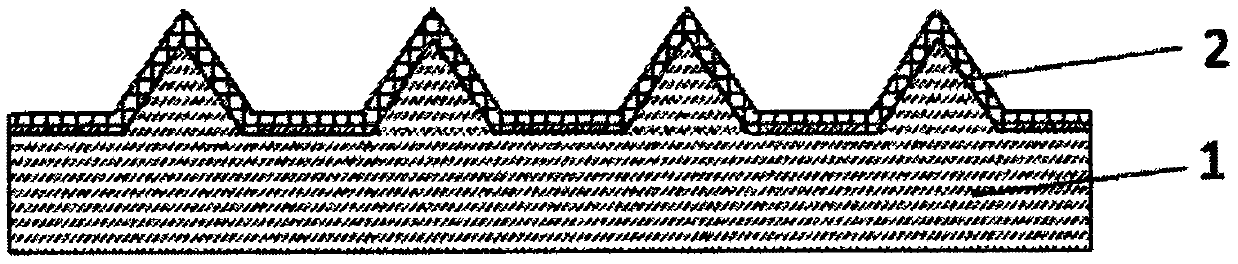

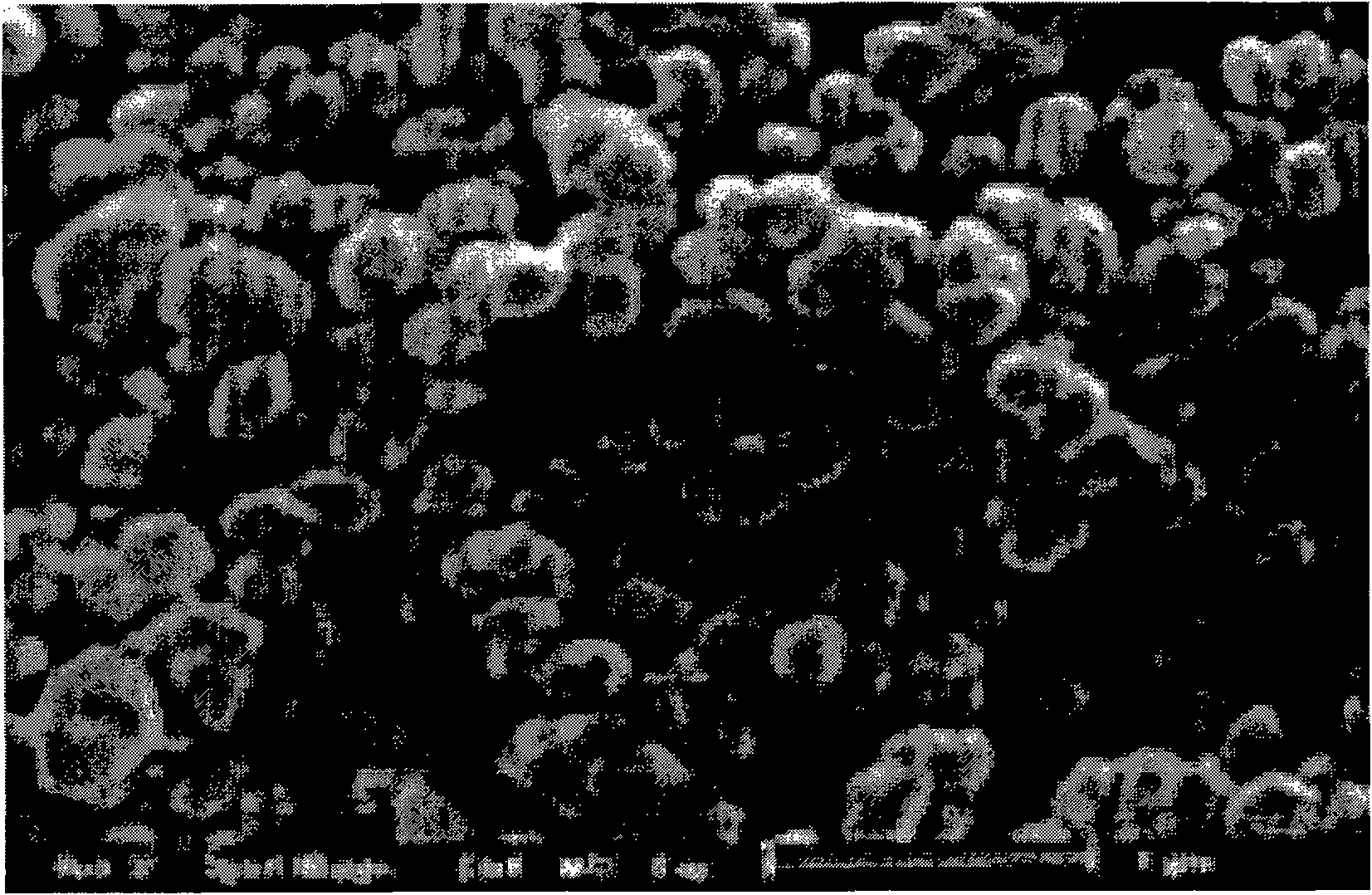

Zirconium disulfide-germanium nano-pyramid heterojunction, preparation method and application thereof

InactiveCN110600562AImprove the shortcomings of high reflectivityModulation of light absorptionFinal product manufacturePhotovoltaic energy generationHeterojunctionSingle crystal

The invention discloses a zirconium disulfide-germanium nano-pyramid heterojunction, a preparation method and an application thereof. The zirconium disulfide-germanium nano-pyramid heterojunction includes a single-side polished monocrystalline germanium wafer with nano-pyramid structure on the surface. A layer of uniform and continuous zirconium disulfide film is arranged on the monocrystalline germanium wafer. The method for preparing the heterojunction according to the present invention comprises the anisotropic etching of the surface of the germanium wafer and the zirconium disulfide preparation by atomic layer deposition. Since the heterojunction of the present invention is a combination of a novel two-dimensional semiconductor zirconium disulfide and a germanium substrate with a three-dimensional nanostructure on the surface, not only can the advantages of the novel two-dimensional material be exerted, but also the light absorption wavelength can be adjusted and the light absorption effect can be enhanced. Further, the atomic layer deposition process can make the zirconium disulfide film completely cover the surface of the germanium substrate and the side walls of the nano-pyramid to achieve comprehensive contact, so that the prepared heterojunction region has large area, thereby improving the photoelectric conversion efficiency of an optoelectronic device.

Owner:ANYANG NORMAL UNIV

Preparation method of nano-zirconium dioxide special for toughening ceramics

The invention discloses a preparation method of nano-zirconium dioxide special for toughening ceramics, belonging to the technical field of inorganic chemical synthesis. The preparation method comprises the steps of firstly mixing polystyrene acrylic acid with dopamine in water under a nitrogen protection condition so as to form a uniform emulsion, complexing dopamine with metal ions in a zirconium oxychloride solution to slowly release the metal ions, introducing air into a flask while dropwise adding ammonia water to generate oxidative polymerization on dopamine under the action of dissolved oxygen in water so as to form a polydopamine network, enabling produced zirconium hydroxide precipitate to be adsorbed to the surface of a polystyrene acrylic acid template by virtue of the formed polydopamine network, carrying out washing to remove impurity ions, drying, and calcining to remove a polystyrene acrylic acid template core and a polydopamine network structure, so as to obtain nano-zirconium dioxide special for the toughening ceramics. The preparation method has the beneficial effects that a preparation process is simple, conditions are controllable, obtained nano-zirconium dioxide is of a uniform shape, and the particle size distribution of nano-zirconium dioxide is relatively narrow.

Owner:常州瑞坦商贸有限公司

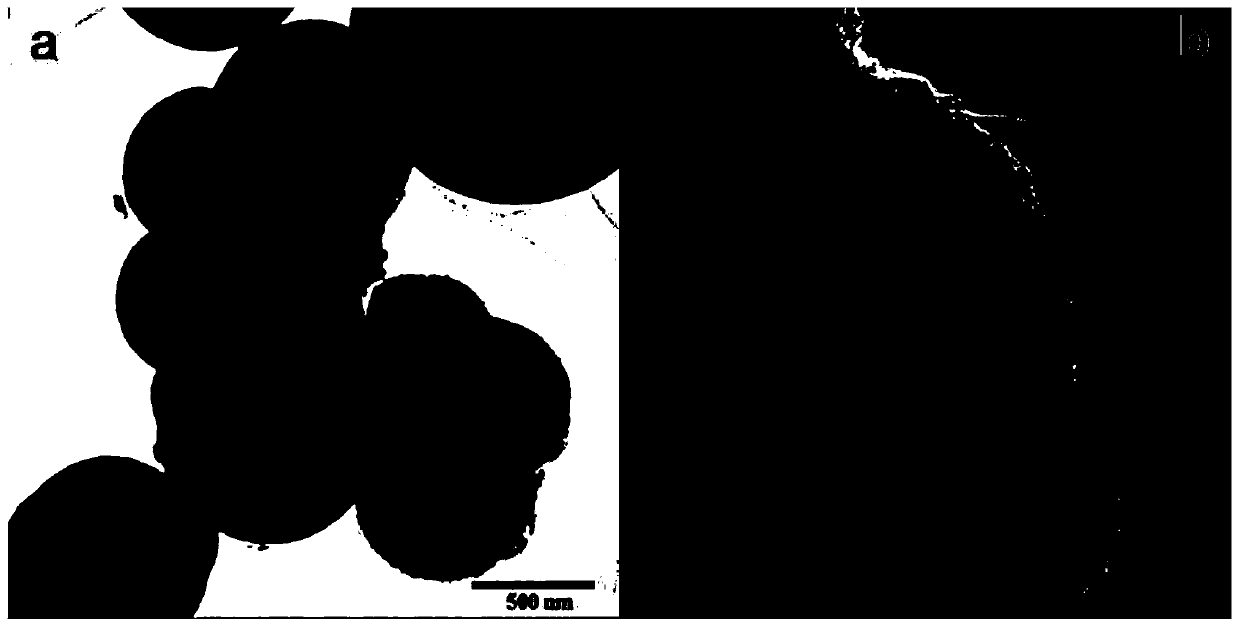

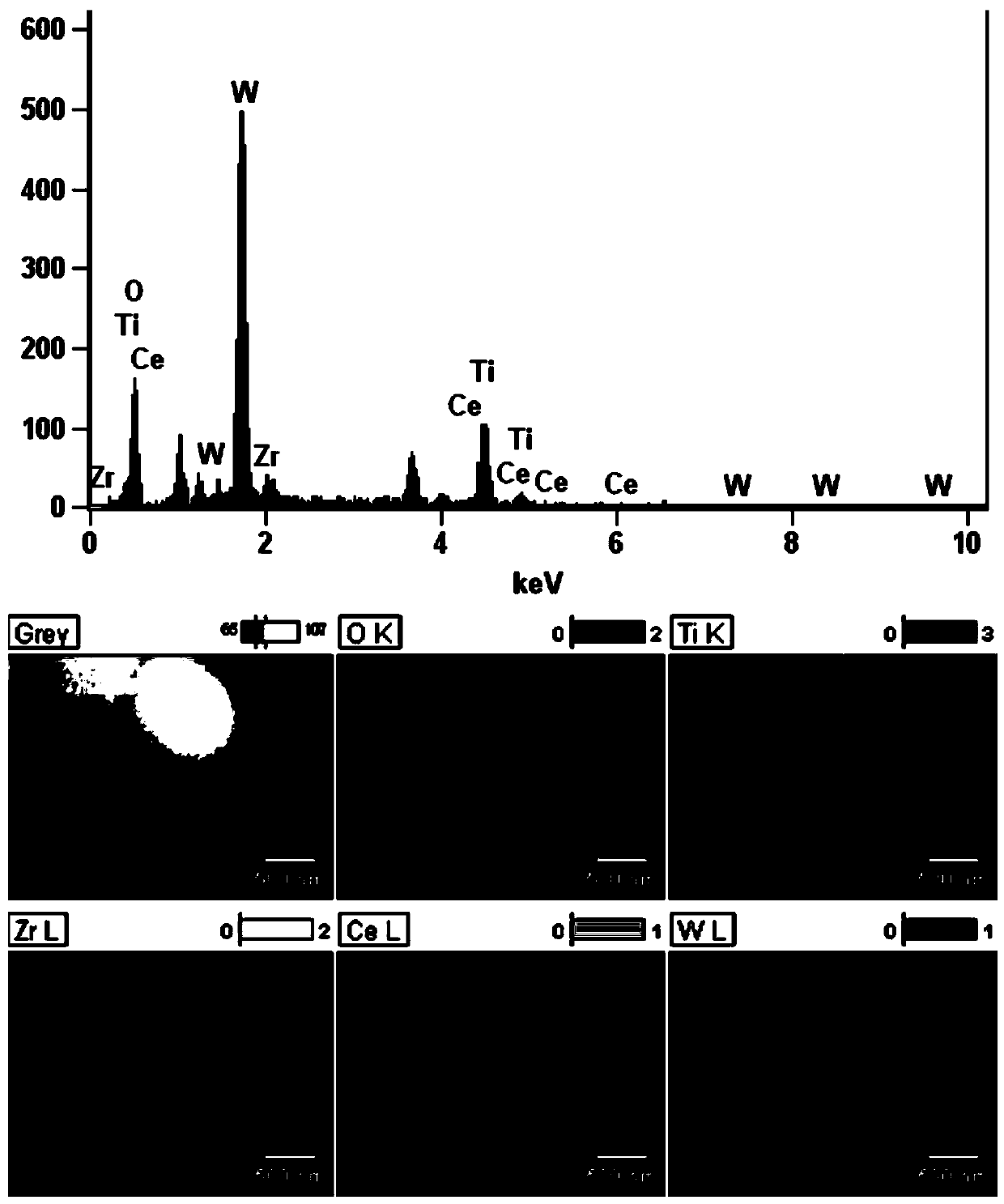

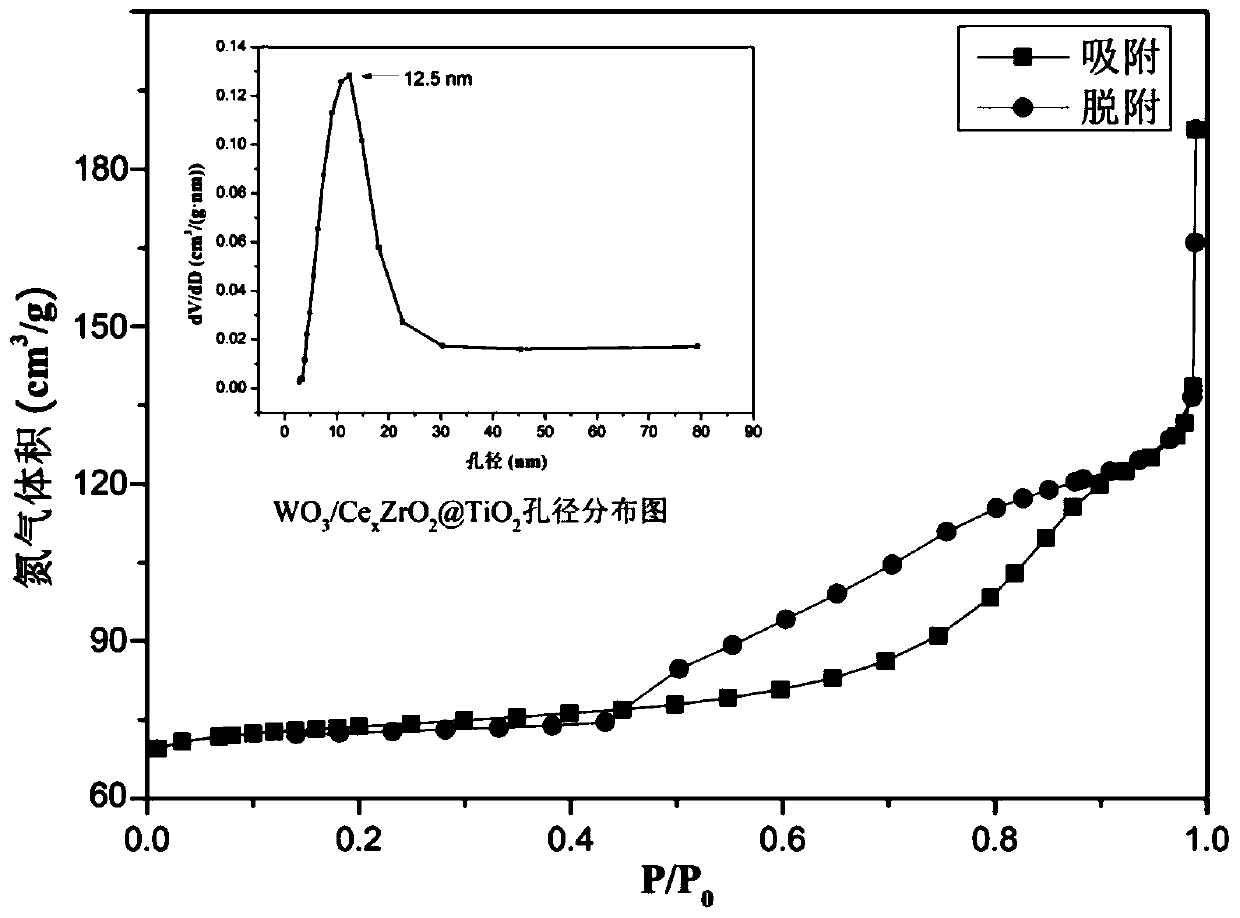

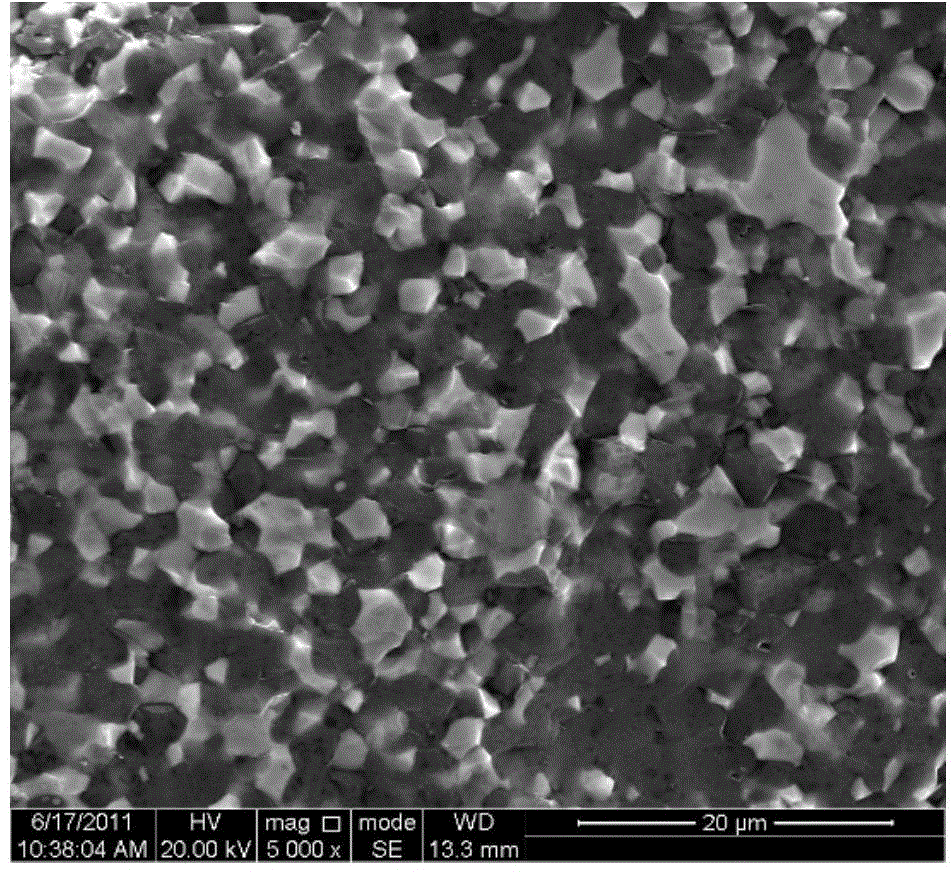

Tungsten-acidified cerium-doped zirconium dioxide coated titanium dioxide solid super acid filler

InactiveCN109908770AIncrease acidityImprove water stabilitySemi-permeable membranesMetal/metal-oxides/metal-hydroxide catalystsZirconium hydrideCalcination

The invention discloses a tungsten-acidified cerium-doped zirconium dioxide coated titanium dioxide solid super acid filler. A preparation method comprises the following steps: 1) mixing TiO2 with absolute methanol, uniformly stirring the mixture, transferring the mixture into water, adding lignin amine, performing dispersion, adding stronger ammonia water and a solution I, conducting a stirring reaction, performing standing and aging at room temperature, performing centrifugation, filtration and washing, taking out a filter cake, performing drying, and performing calcination to obtain a lightyellow precursor; 2) impregnating the precursor in an ammonium tungstate aqueous solution, taking out and drying the precursor, and performing calcination to obtain the tungsten-acidified cerium-doped zirconium dioxide coated titanium dioxide solid super acid filler. The filler has better acidity, water stability and heat stability, can be applied to liquid phase reactions and can inhibit membrane pollution phenomena under the action of photocatalysis and solid super acid and improve pollution resistance of membranes. Pore size distribution of core-shell particles is centralized in the mesoporous range, adsorption and transfer processes of pollutants on particle surfaces are facilitated, and photocatalytic efficiency can be improved.

Owner:TIANJIN UNIV

Zirconium diboride-silicon carbide-copper nickel electrode material and preparation method thereof

Belonging to the technical field of electrical discharge machining electrode material application, the invention in particular relates to a zirconium diboride-silicon carbide-copper nickel electrode material and a preparation method thereof. The electrode material is composed of 55%-65% of zirconium diboride powder, 20%-40% of copper nickel powder mixed silicon carbide powder, and 5%-15% of copper-nickel mixed powder, wherein the copper-nickel mixed powder is formed by ball mill mixing of copper powder and nickel powder in a mass ratio of 9:1. According to the invention, by introducing silicon carbide powder and copper nickel powder into the zirconium diboride composite material system, on the one hand, the conductive property of the zirconium diboride based composite material is greatly improved, and on the other hand, the high temperature strength and ablation resistance of the material are improved. At the same time, mechanical alloying is utilized to lower the sintering temperature of the zirconium diboride composite material, thus preparing the zirconium diboride composite material with excellent performance.

Owner:HARBIN INST OF TECH

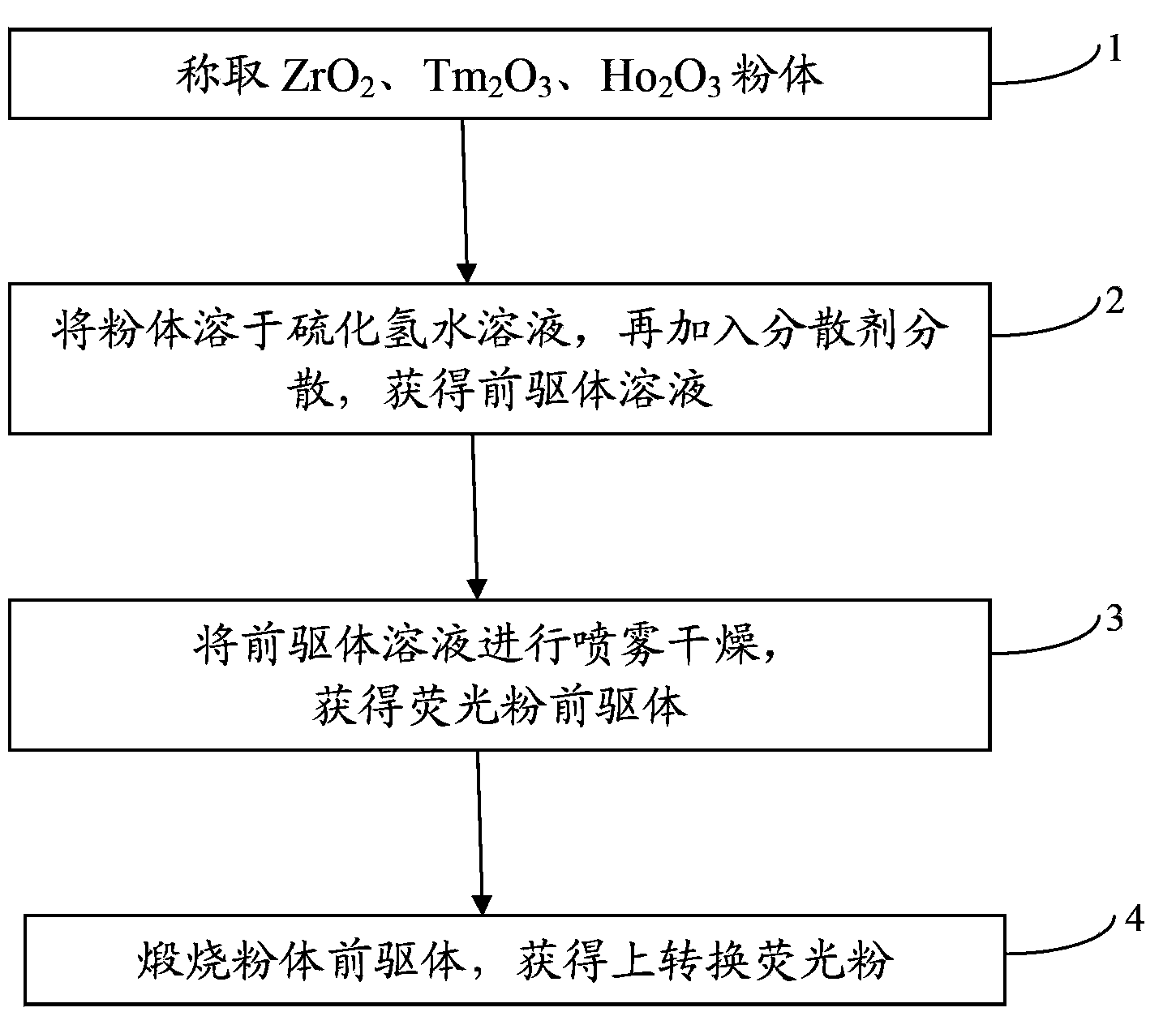

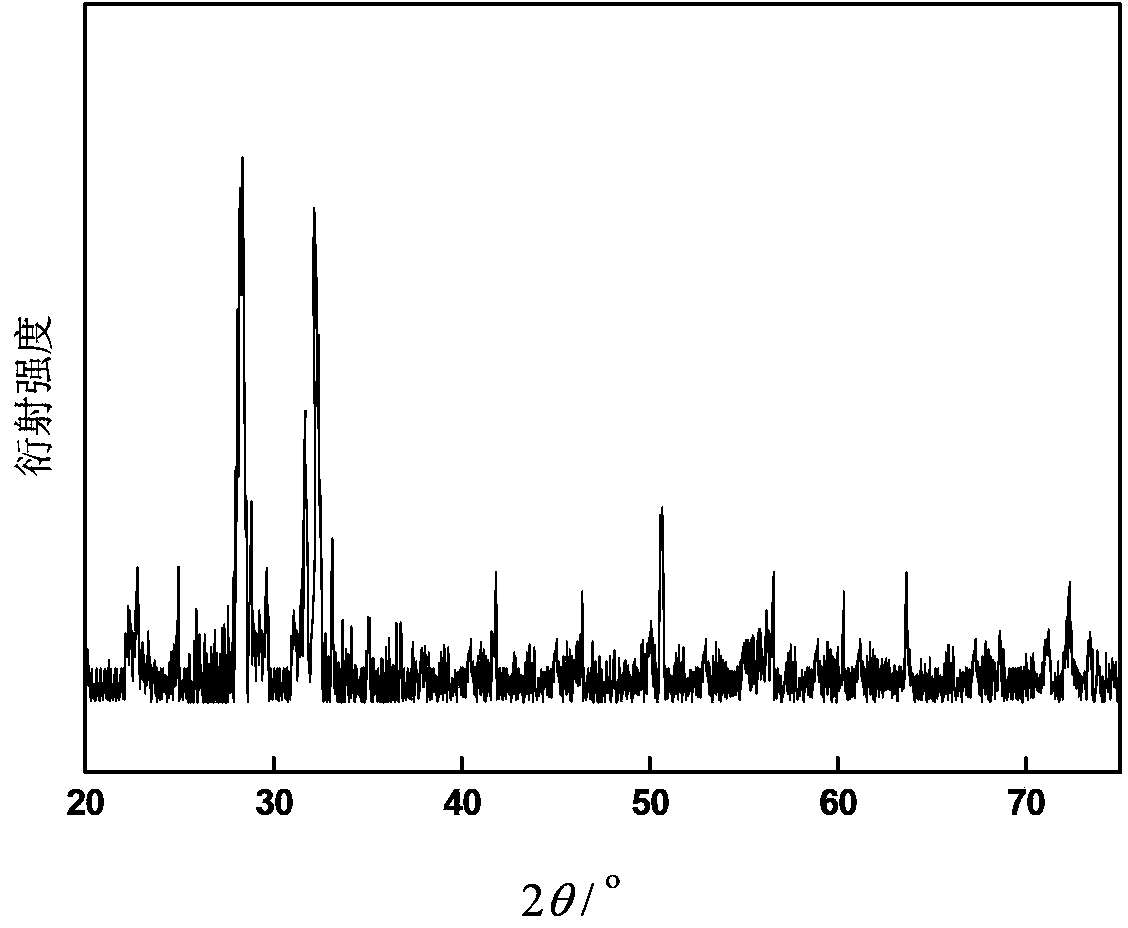

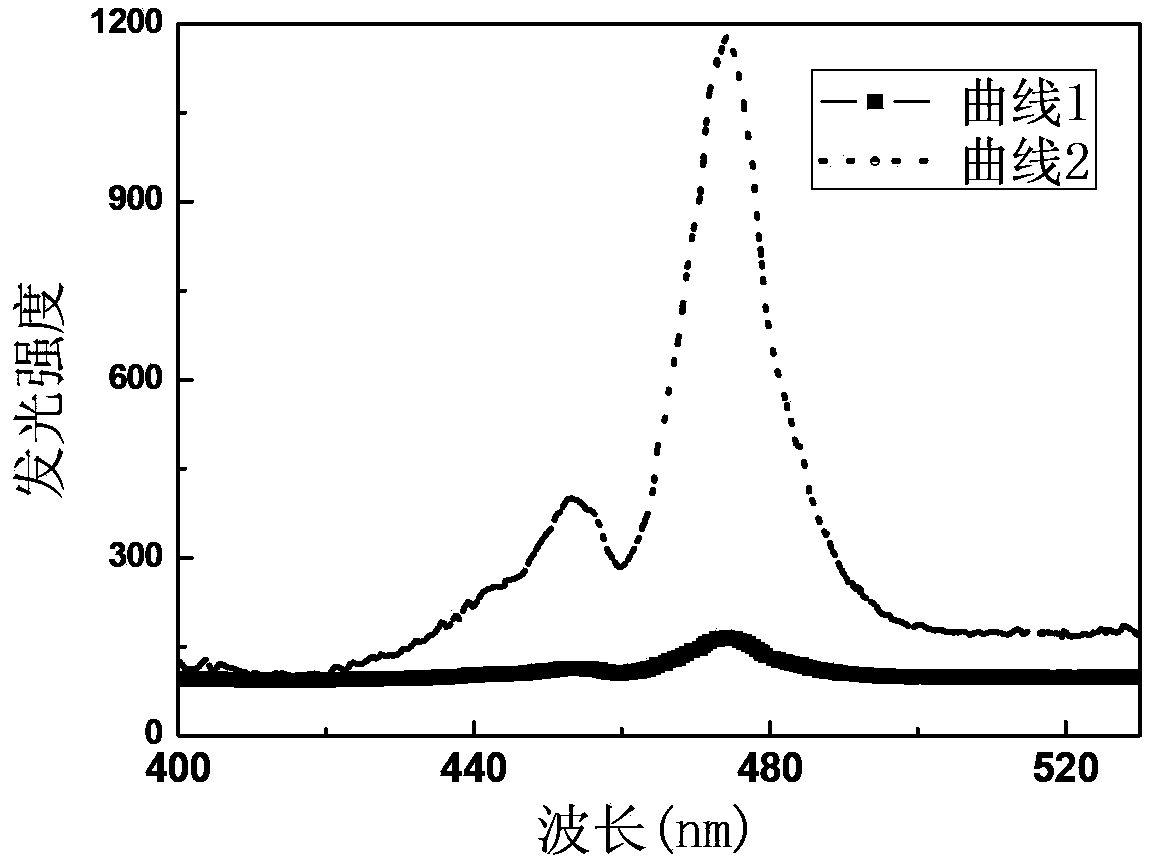

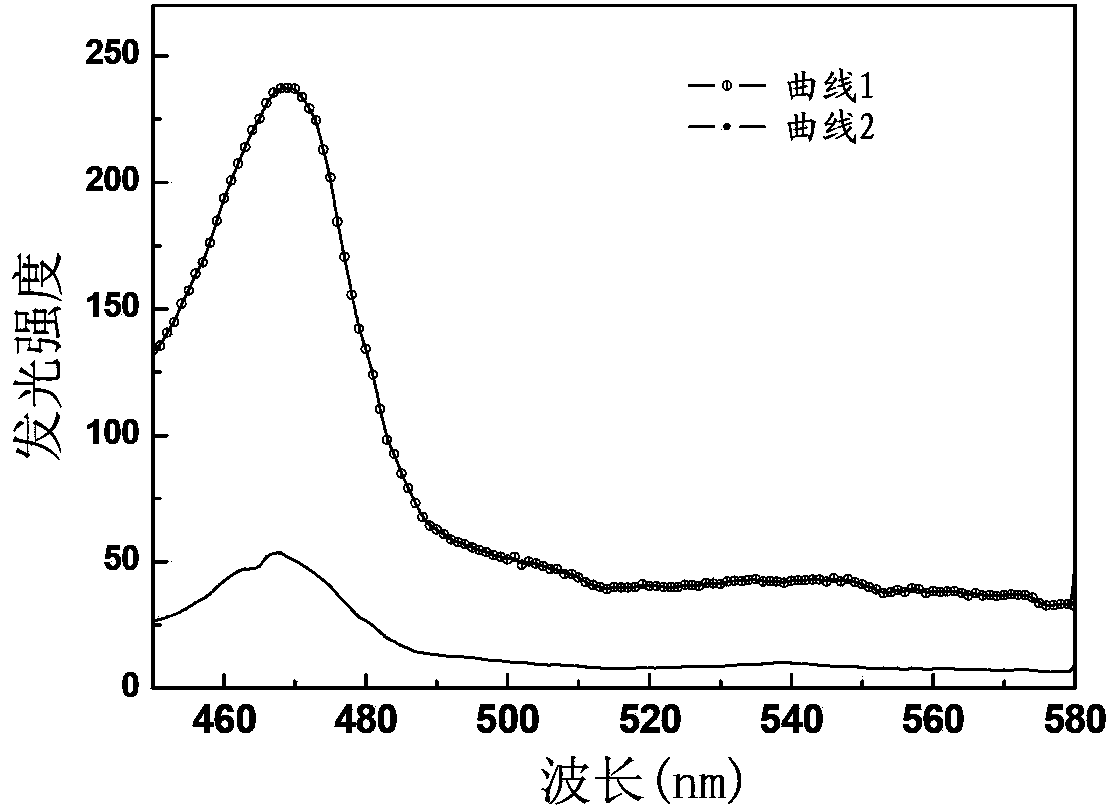

Tm/Ho co-doped disulfide zirconium upconversion fluorescent powder and preparation method and application thereof

InactiveCN104342135AImprove up-conversion luminous efficiencyImprove efficiencySolid-state devicesSemiconductor/solid-state device manufacturingCrystal structureLong wave radiation

The invention provides Tm / Ho co-doped disulfide zirconium upconversion fluorescent powder, the chemical general formula of which is ZrS2: xTm<3+>, yHo<3+>, wherein ZrS2 is a substrate, Tm<3+> and Ho<3+> are doping ions, the value range of x is 0.002-0.06 and the value range of y is 0.002-0.04. The fluorescent powder can be excited by long-wave radiation from infrared rays to green light for blue-light short wave emission, so that the deficiencies of blue light materials in the existing luminescent materials can be overcome. The invention further provides a preparation method of the Tm / Ho co-doped disulfide zirconium upconversion fluorescent powder. The method can be used for preparing the Tm / Ho co-doped disulfide zirconium upconversion fluorescent powder which has the advantages of less surface defects, good degree of crystallinity and relatively intact crystal structure. In addition, the invention further provides an application of the Tm / Ho co-doped disulfide zirconium upconversion fluorescent powder in preparation of organic electroluminescence devices.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

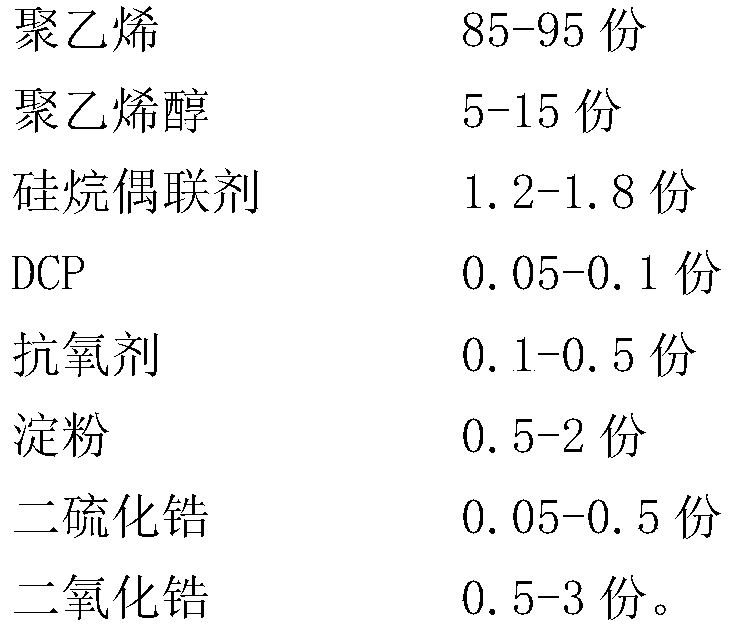

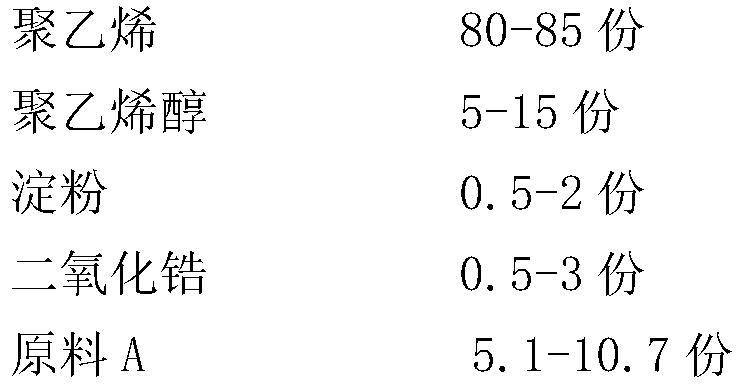

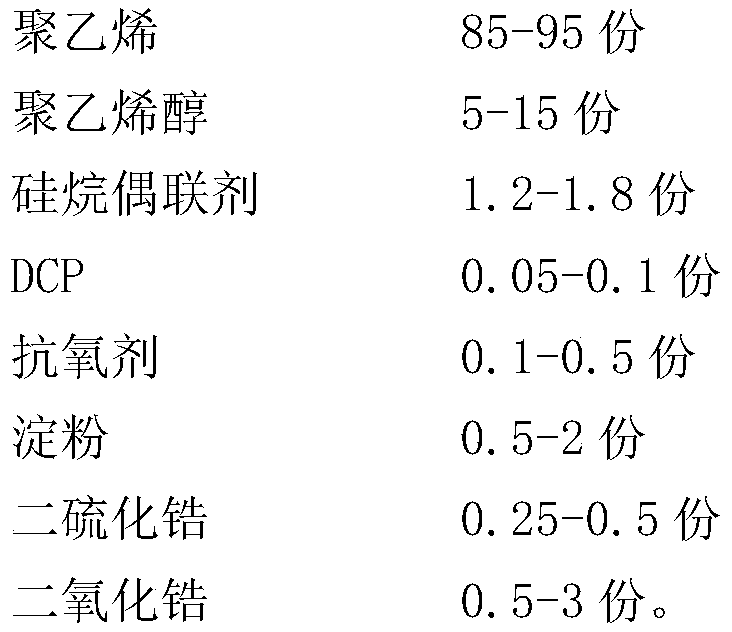

Silane crosslinked polyethylene cable insulation material

ActiveCN110240744AShort crosslinking timeImprove mechanical propertiesPlastic/resin/waxes insulatorsSilanesAntioxidant

The invention discloses a silane crosslinked polyethylene cable insulation material, which is prepared from the following components in parts by weight: 85-95 parts of polyethylene, 5-15 parts of polyvinyl alcohol, 1.2-1.8 parts of a silane coupling agent, 0.05-0.1 part of dicumyl peroxide (DCP), 0.1-0.5 part of an antioxidant, 0.5-2 parts of starch, 0.05-0.5 part of zirconium disulfide and 0.5-3 parts of zirconium dioxide. The silane crosslinked polyethylene cable insulation material is prepared without using a catalyst with stronger toxicity, is shorter in crosslinking time, and has better thermal aging resistance.

Owner:浙江太湖远大新材料股份有限公司

Titanium dioxide coated zirconia powder and preparation method thereof

ActiveCN105110369BGood compatibilityImprove sintering performanceZirconium oxidesPorosityZirconium hydride

Owner:淄博裕民基诺新材料有限公司

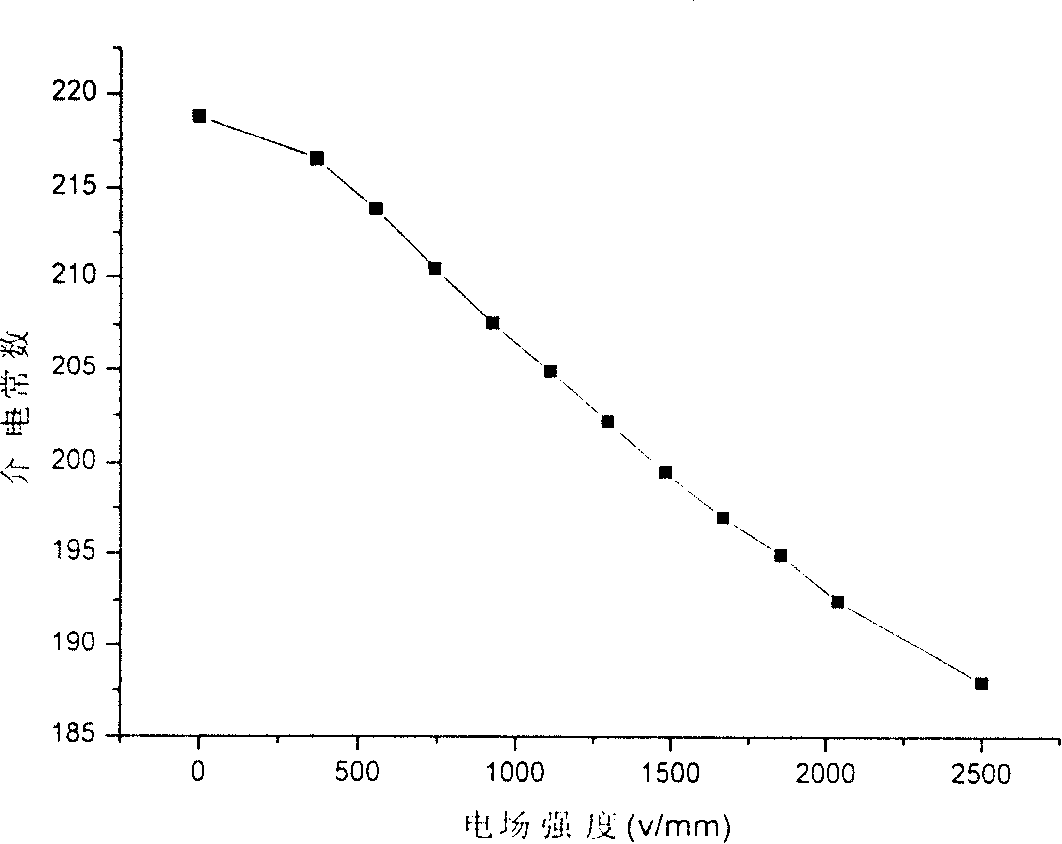

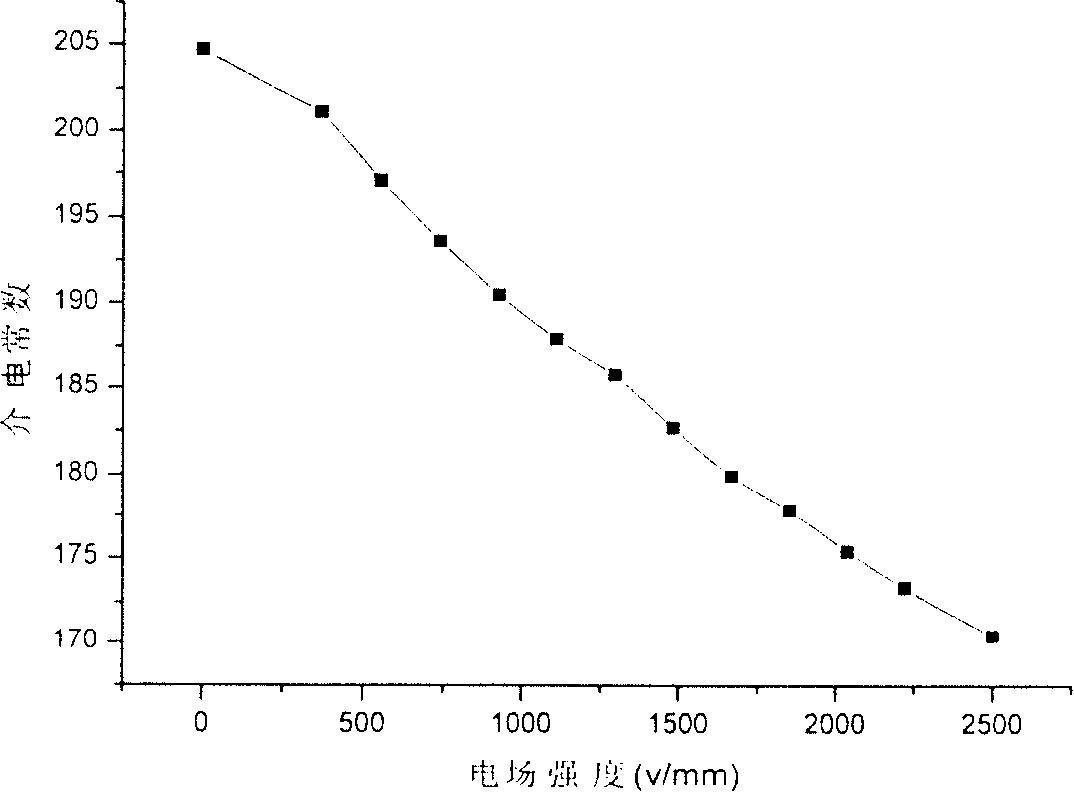

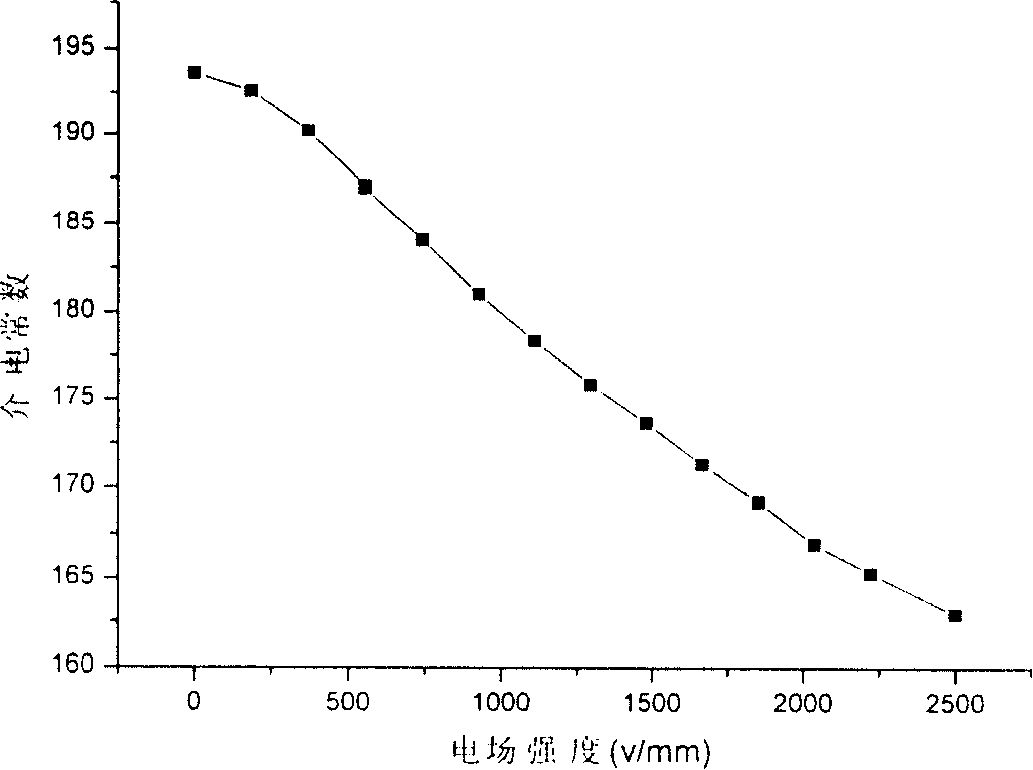

Zirconium dioxide mixed modified barium strontium phthalate-magnesium oxide base composite and preparation process thereof

InactiveCN100404458CImprove adjustabilityLow dielectric constantZirconium hydrideBarium strontium titanate

The invention relates to a zirconium dioxide doping modifying barium strontium titanate-MgO based (Ba1-xSrxTiO3 / MgO) compounding material and the manufacture method. The basal body is barium strontium titanate and MgO. Trace quantity of zirconium dioxide is doped in to modify. The constitutes are (1-y)Ba1-xSrxTiO3+yMgO+zZrO 2, of which 0.35<=x<=0.45, y=50wt%, Owt%1-xSrxTiO3(BSTO) powder from BaCO3, SrCO3, and TiO2; mixing the powder with MgO and ZrO2 to make compounding material. The result shows zirconium dioxide doping sharply increases the adjustability of dielectric constant, and has low dielectric constant, low microwave consumption, etc.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

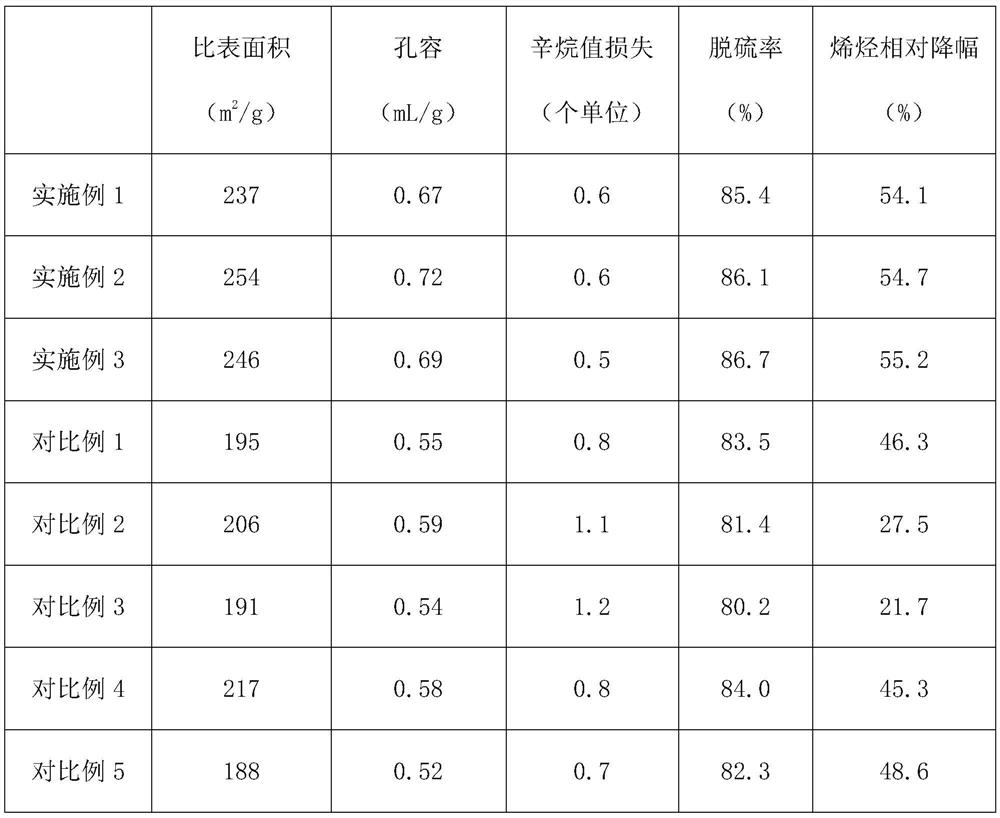

Gasoline hydrofining catalyst and preparation method thereof

InactiveCN113385180AHigh reactivityIncreased dispersionMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsAluminum IonPtru catalyst

The invention discloses a gasoline hydrofining catalyst and a preparation method thereof, and the preparation method comprises the following steps: (1) taking pseudo-boehmite and sodium hydroxide, conducting stirring and mixing, and adding silica sol to prepare a carrier A; (2) adding sulfur into the carrier A and nano aluminum powder, and conducting roasting to obtain a carrier B; (3) dipping and roasting zirconium isopropoxide, and introducing carbon disulfide for reaction to prepare a carrier; (4) mixing cobalt nitrate, ammonium heptamolybdate and an auxiliary agent, and conducting dipping and roasting to prepare a catalyst C; and (5) conducting vulcanizing to obtain the catalyst. Pseudo-boehmite and silica sol are taken to prepare the carrier A, the carrier A reacts with sulfur and nano aluminum powder to form a carrier B, zirconium isopropoxide is used as a raw material to prepare zirconium oxide through roasting, then zirconium oxide reacts with carbon disulfide to prepare zirconium disulfide, and the zirconium disulfide is embedded with aluminum ions to prepare the carrier, so that the micropore specific surface area of the prepared carrier can be increased, the electrical property is good, electron transfer is promoted, the reaction activity is improved, and the hydrogenation performance of the prepared catalyst is improved.

Owner:郑州瑞尔铁路安全技术有限责任公司

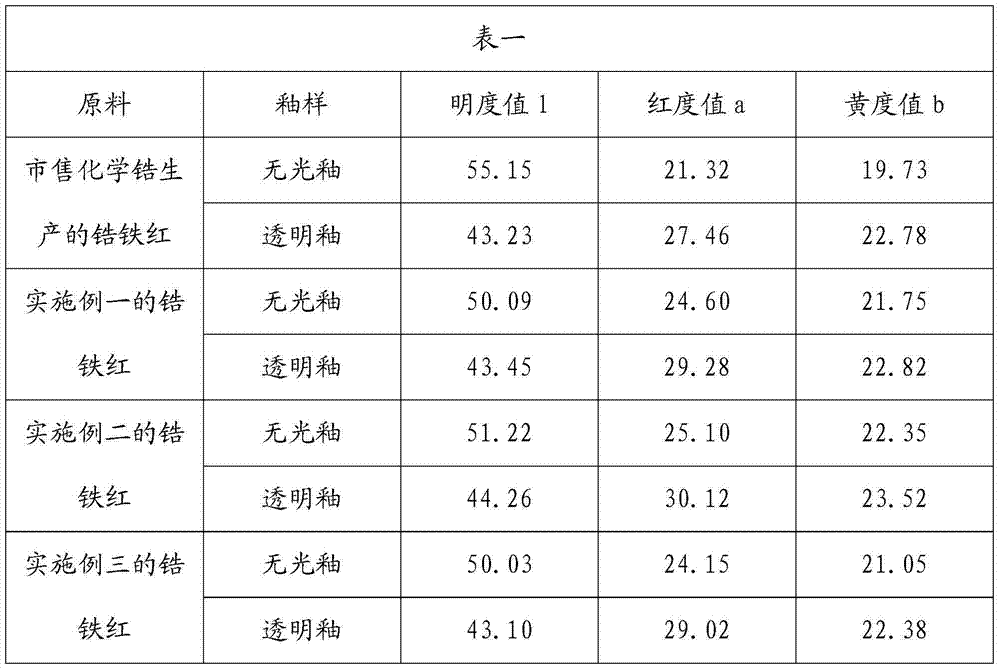

Ferrozirconium red material

Owner:SHENGQUAN FUJIAN GLAZE MAKING CO LTD

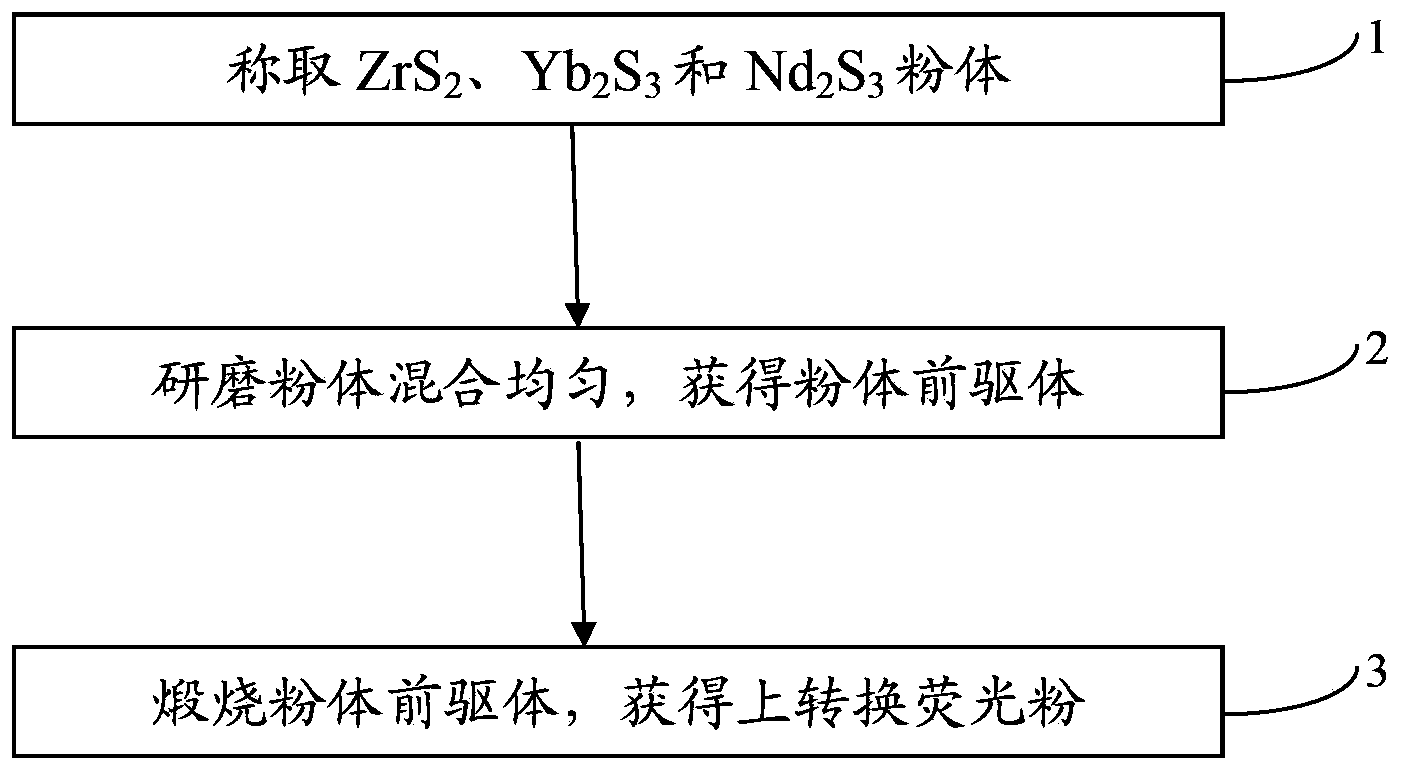

Neodymium-ytterbium codoped zirconium sulfide up-conversion fluorescent powder, as well as preparation method and applications thereof

InactiveCN104342133ARich energy levelLong energy lifeSolid-state devicesSemiconductor/solid-state device manufacturingUp conversionPhotochemistry

The invention provides neodymium-ytterbium codoped zirconium sulfide up-conversion fluorescent powder, with the general chemical formula of Zr<1-x-y>S<2>:xYb<3+>, yNd<3+>, wherein ZrS2 is a matrix, Yb and Nb are doping elements, x ranges from 0.01 to 0.1, and y ranges from 0.004 to 0.06. The fluorescent powder is excited by infrared-green ray long-wave radiation to emit blue short-wave ray and can make up the deficiencies of the blue-ray material in the current luminescent material. The invention further provides a preparation method of the neodymium-ytterbium codoped zirconium sulfide up-conversion fluorescent powder. The preparation method is simple and low in production cost and can be popularized and applied. In addition, the invention further provides applications of the neodymium-ytterbium codoped zirconium sulfide up-conversion fluorescent powder in preparation of an organic electroluminescence device.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

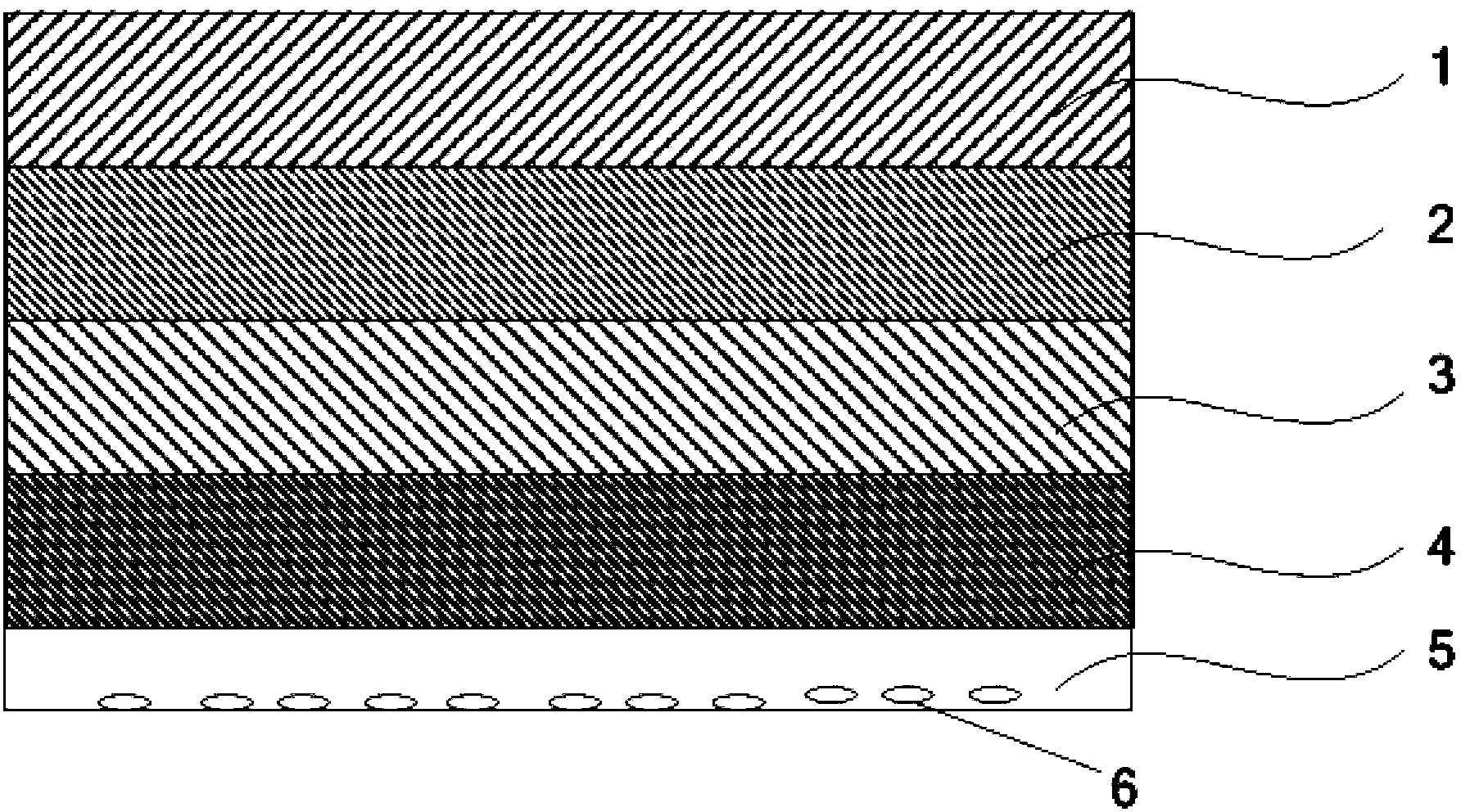

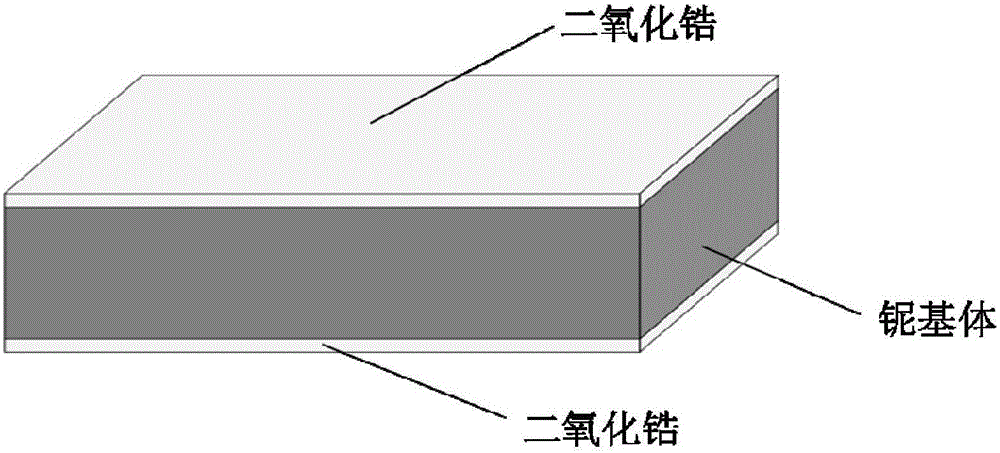

A kind of preparation method of zirconium dioxide-niobium high temperature resistant layered composite material

InactiveCN103590035BSolve delaminationVacuum evaporation coatingSputtering coatingZirconium hydrideNiobium

The invention relates to a preparation method for a high-temperature-resistant laminated composite zirconium dioxide-niobium material. The preparation method comprises the following steps: preprocessing of a niobium sheet, zirconium plasma injection, drawing of a zirconium dioxide film on the surface of the niobium sheet through the sol-gel method, and high-temperature sintering. The invention has the advantages that through the vacuum metal plasma injection technology, the metallic element zirconium is injected into the pickled and etched niobium metal test sheet according to a certain amount of energy and dosage, so as to solve the problem that the zirconium dioxide film easily cracks due to the large differences between niobium and zirconium dioxide in ion size as well as between coefficients of thermal expansion; the niobium metal test sheet is covered by the zirconium dioxide film through the vertical drawing method of a zirconium sol-gel solution; the niobium sheet and the zirconium dioxide film are subjected to high-temperature annealing and sintering together to prepare the high-temperature-resistant laminated composite zirconium dioxide-niobium material. According to the composite zirconium dioxide-niobium material, the niobium sheet and the zirconium dioxide film are directly compounded in a laminated manner, so that the high-temperature-resistant property of the niobium sheet and the zirconium dioxide film is preserved. Therefore, the composite zirconium dioxide-niobium material achieves a very good application potential in the high-temperature field.

Owner:TIANJIN UNIV

Preparation method of zirconium dioxide powder

The invention relates to a preparation method of zirconium dioxide powder, comprising the following steps: A. dissolving zirconium oxychloride into deionized water, and controlling mass ratio of the zirconium oxychloride and the deionized water to be 4:(21-35); B. dropwise adding ammonia water into mixed solution in the step A, and controlling mole ratio of the ammonia water and the zirconium oxychloride to be (1.8-3.7):1; C. carrying out washing, pressing and filtering or centrifugal separation on zirconium hydroxide hydrogel in the step B to obtain zirconium hydroxide gel; D. drying the zirconium hydroxide gel of the step C to obtain zirconium hydroxide, and calcining the zirconium hydroxide to obtain zirconium dioxide; E. mixing the zirconium dioxide in the step D with grinding medium and water and carrying out wet grinding on the mixture; and F. drying the zirconium dioxide slurry in the step E to prepare the zirconium dioxide powder. The zirconium dioxide powder product produced by the method has good particle monodispersity, complete particle form, concentrating distribution of particle size, high purity and controllable particle size and can realize low cost when in large-scale production of the zirconium dioxide.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

Glass inner container for the electric cooker and the processing technics thereof

InactiveCN100463634CBeautiful appearanceEasy to cleanCooking-vessel materialsDissolutionSilicon dioxide

The invention discloses a glass inner container for the electric cooker which is made of silica dioxide, aluminum oxide, zirconium dioxide and boric oxide, wherein the silica dioxide is the basic raw material, the weight percentage of the raw material is that the silica dioxide is of 70-80%, the aluminum oxide is of 1-3%, the zirconium dioxide is of 3-8% and the boric oxide is of 10-20%. The producing method of the glass inner container for the electric cooker is that A: the raw material is prepared proportionally; B: the prepared raw material is mixed evenly by a mixing machine; C: the raw material which is mixed evenly is sent into the dissolution pool and is heated to the temperature of 1400-1600 DEG C, thus forming glass liquid; D: the glass liquid is sent into the working pool to carry out depositing and filtering disposal; E: the glass liquid is sent to the formed press mold and is produced into an end product. The glass inner container produced by the adopted art is thermostable, beautiful in appearance, convenient in cleaning, and the glass product meets the demand of the human and the current society for different aspect of the product such as health, environment protection and so on.

Owner:湖北九龙泰环保科技有限公司

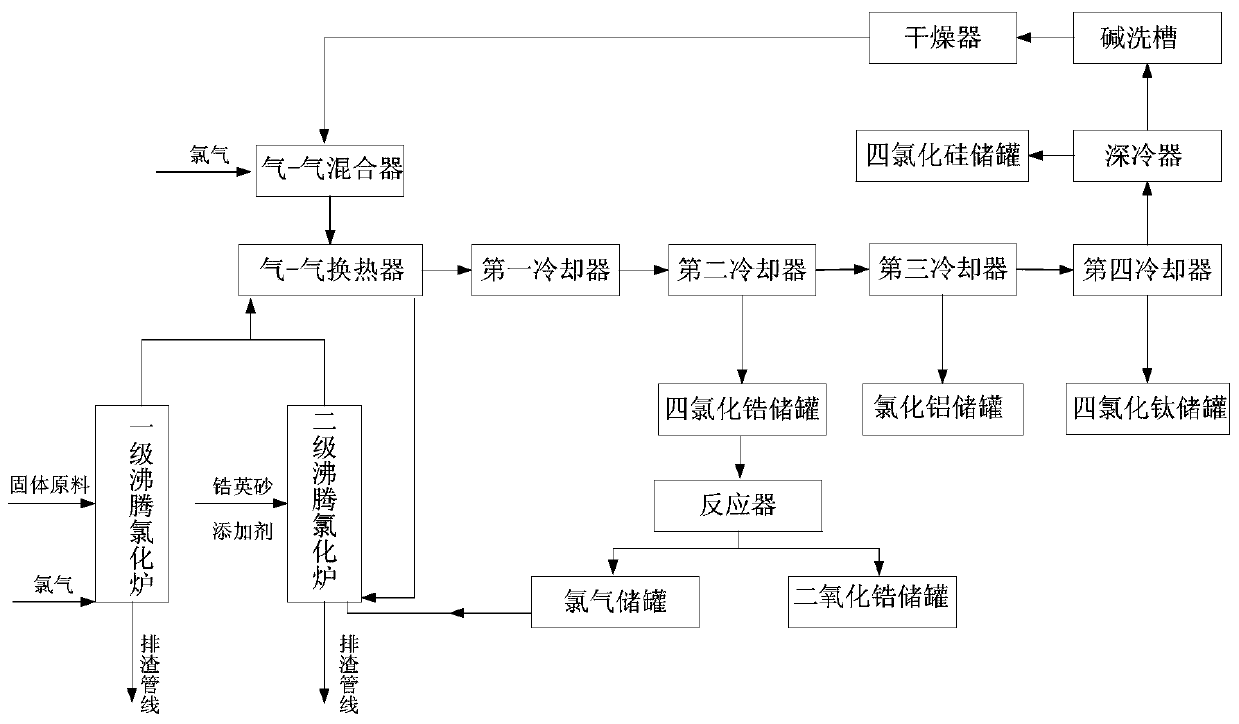

Preparation technology of zirconium tetrachloride and zirconium dioxide

ActiveCN108557880BRealize joint productionRealize comprehensive utilizationZirconium oxidesZirconium halidesTetrachlorideSilicon tetrachloride

The invention discloses preparation processes of zirconium tetrachloride and zirconium dioxide. The preparation process of zirconium tetrachloride comprises the following steps that 1, zircon sand, acarbon reducing agent and chlorine are added into a primary fluidizing chlorination furnace, heating is performed, primary chlorination reaction is performed to generate zirconium tetrachloride, silicon tetrachloride, carbon monoxide and carbon dioxide, and a first gas mixture is obtained; 2, the carbon monoxide is separated from the first gas mixture and is introduced into a secondary fluidizingchlorination furnace, the zircon sand and the chlorine are added into the secondary fluidizing chlorination furnace, heating is performed, secondary chlorination reaction is performed to generate zirconium tetrachloride, silicon tetrachloride and carbon dioxide, and a second gas mixture is obtained. The primary chlorination reaction and secondary chlorination reaction in the process can promote reaction of CO serving as a reducing agent, the CO having reducing potential and produced by the primary chlorination reaction can be fully and effectively utilized by coupling the primary chlorinationreaction and the secondary chlorination reaction, the input of reaction raw materials in the whole process is reduced, accordingly the production cost is reduced, and discharge of greenhouse gas is decreased.

Owner:XINJIANG JINGSHUO NEW MATERIALS CO LTD

Production process of tetrahydrated zirconium sulfate

The invention provides a production process for producing zirconium sulfate tetrahydrate by using zirconium salts or alkali compounds and sulfuric acid as raw materials. Specifically, zirconium salts or alkali compounds are mixed with water and sulfuric acid in a certain proportion, and after full stirring and grinding, they are completely reacted to produce zirconium sulfate tetrahydrate. The above-mentioned process adopts the method of mixing and reacting zirconium salts or alkali compounds directly with sulfuric acid, which has the characteristics of simple equipment, short process flow, high yield, and no discharge of three wastes. It can be used to produce high-purity zirconium sulfate tetrahydrate and produce zirconium Treatment of zirconium compounds recovered from serial chemical production processes.

Owner:柳云珍

Method for preparing rear-earth modified zirconium diboride/aluminum oxide composite powder

InactiveCN101182191BPromote sinteringImprove antioxidant capacitySelf-propagating high-temperature synthesisRare earth

The invention relates to a preparation method of zirconium / aluminum trioxide compound powder which has anti-oxidant property and easily-sintered surface which is coated by nanometer rare earth oxide. The method is characterized in that the method includes the steps as follows: 1), balling-milling zirconium dioxide ZrO2, diboron trioxide B2O3 and metal Aluminum Al powder uniformly and molding and shaping, placing in a self-propagating high temperature synthesizer at room temperature under the protection of argon, igniting and burning, and obtaining high pure ZrB2 / Al2O3 ceramic compound powder after combustion products are grinded; 2) adding the ZrB2 / Al2O3 ceramic compound powder in rare earth salt solution, mixing into uniform slurry, drying and obtaining the compound powder of precursor ZrB2 / Al2O3 compound powder with the rare earth oxide coating layer; 3) sintering the compound powder at high temperature to obtain a final product. The invention has the advantages of simple operation, convenience and little energy and time consumption. The synthesized powder has the advantages of high purity, small grain, sintering easiness and good high temperature oxidation resistance.

Owner:FUDAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com