Zirconium dioxide mixed modified barium strontium phthalate-magnesium oxide base composite and preparation process thereof

A technology of zirconia and composite materials, which is applied in the fields of zirconia-doped modified strontium barium titanate-magnesia-based composite materials and its preparation, materials for phased array phase shifters, and can solve the problem of low dielectric constant and Microwave loss, low material adjustability, high microwave loss and other problems, to achieve the effect of low dielectric constant, improved adjustability, and low microwave loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] powdered BaCO 3 , SrCO 3 ,TiO 2 As the raw material, according to the stoichiometric ratio, wet ball milling for 24 hours, pre-calcined at 1150°C after discharging and drying, and kept for 2 hours to obtain Ba 1-x Sr x TiO 3 (x=0.45); according to (1-y) Ba 1-x Sr x TiO 3 +yMgO+zZrO 2 (x=0.45, y=50wt%, z=0.5wt%) proportioning, after wet ball milling for 24 hours, discharging, drying, briquetting, pre-burning at 1200°C and keeping it warm for 2 hours. Crush and grind the block, After 48 hours of wet fine grinding, discharge and dry, add 7wt% PVA to granulate and shape, and press the powder under a pressure of 100MPa; deglue in the temperature range of 750°C-850°C, and keep it warm for 1-2 hours. Exclude the organic substances in the green body, the heating rate of the debinding process is not higher than 3°C / h; sinter in the temperature range of 1350°C-1450°C, and hold for 2h. The fired samples were finely ground, ultrasonically cleaned, and silver electrodes wer...

Embodiment 2

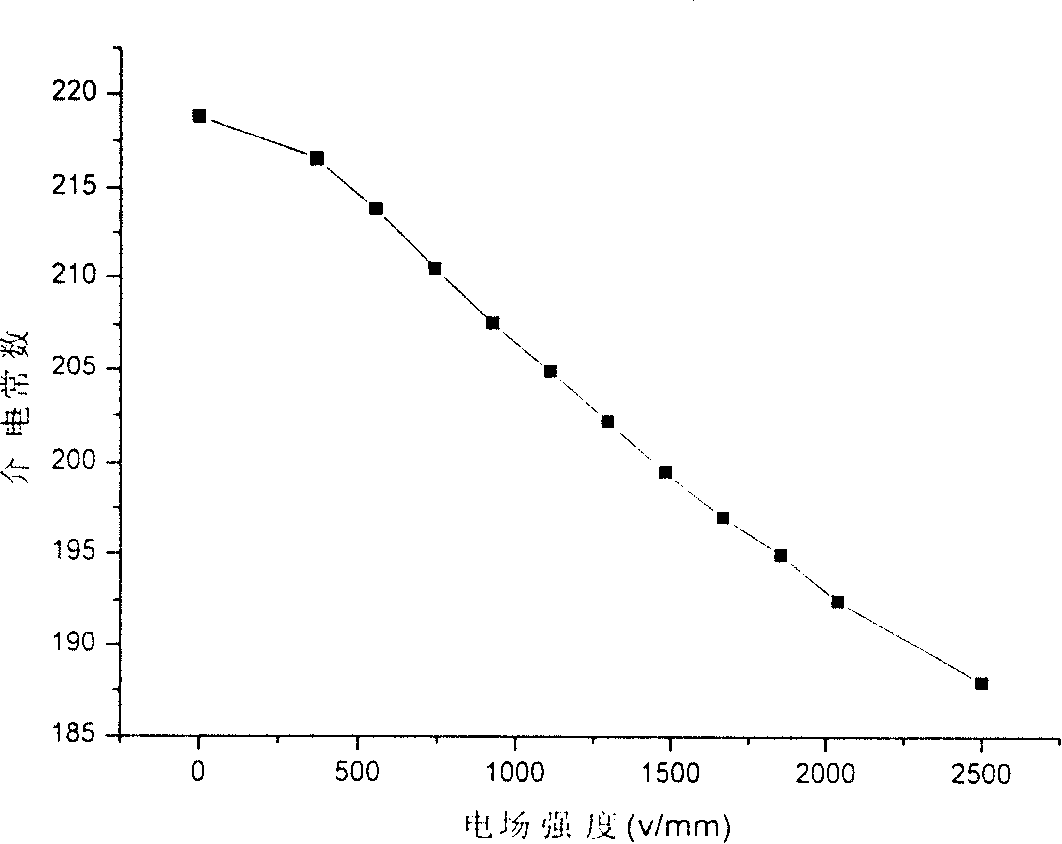

[0042] According to (1-y)Ba 1-x Sr x TiO 3 +yMgO+zZrO 2 (x=0.45, y=50wt%, z=1.0wt%) proportioning, concrete process route is identical with embodiment 1. The electric property of component described in this embodiment is shown in Table 2. figure 2 The variation curve of the dielectric constant of the components described in this embodiment with the bias voltage is given, Figure 6 Shown is the curve of the dielectric constant of the components described in this example as a function of temperature.

[0043] The electrical performance of the component described in table 2 embodiment 2

[0044]

Embodiment 3

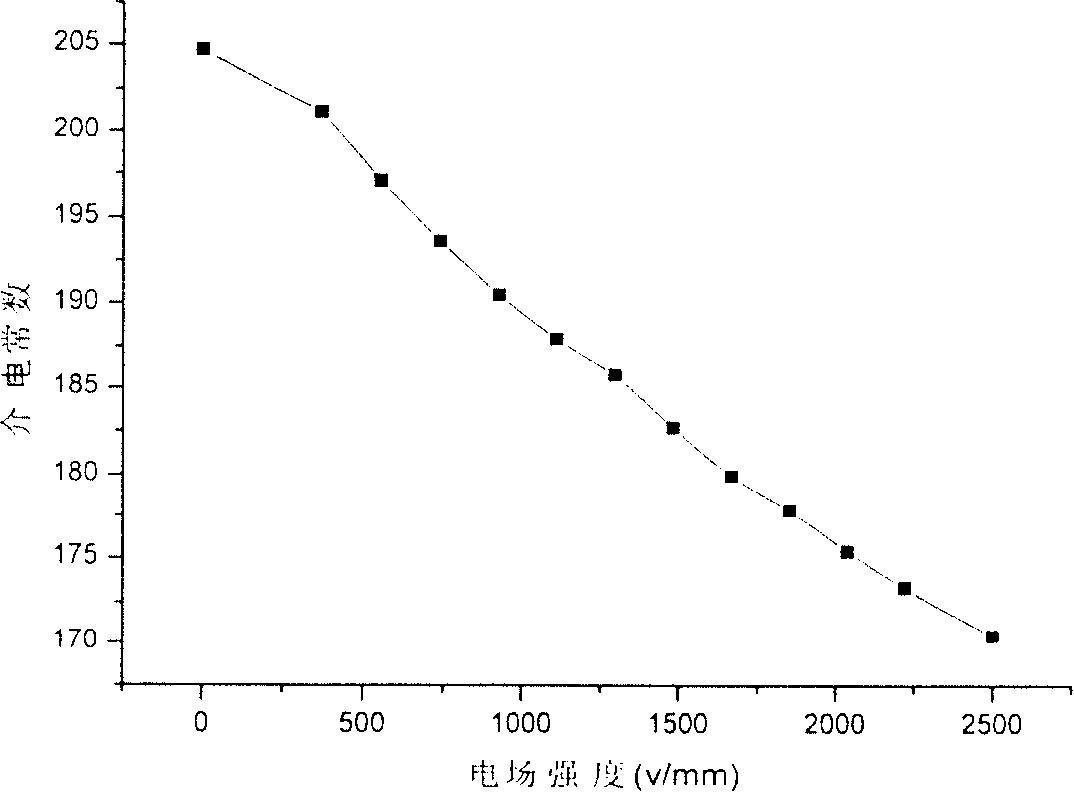

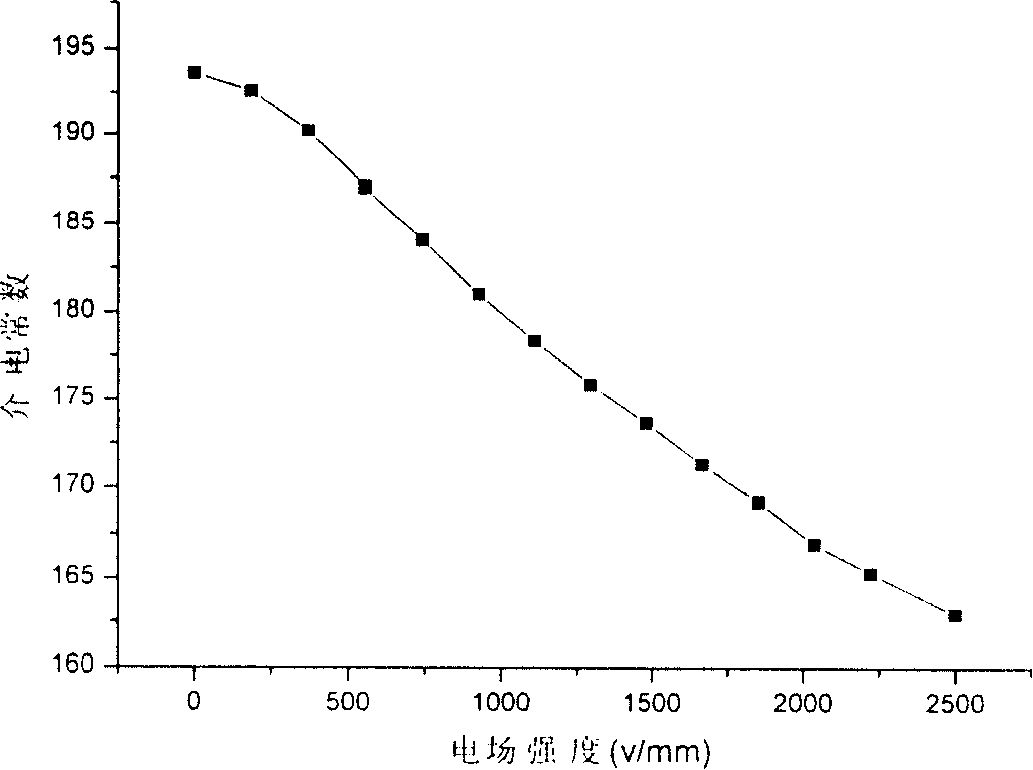

[0046] According to (1-y)Ba 1-x Sr x TiO 3 +yMgO+zZrO 2 (x=0.45, y=50wt%, z=2.0wt%) proportioning, specific process route is identical with embodiment 1. The electric property of component described in this embodiment is shown in Table 3. image 3 The variation curve of the dielectric constant of the components described in this embodiment with the bias voltage is given, Figure 7 Shown is the curve of the dielectric constant of the components described in this example as a function of temperature.

[0047] The electrical performance of the component described in table 3 embodiment 3

[0048]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com