Tm/Ho co-doped disulfide zirconium upconversion fluorescent powder and preparation method and application thereof

A technology of co-doping and disulfide, applied in the field of phosphor powder, to achieve the effect of uniform mixing of components, good dispersibility and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

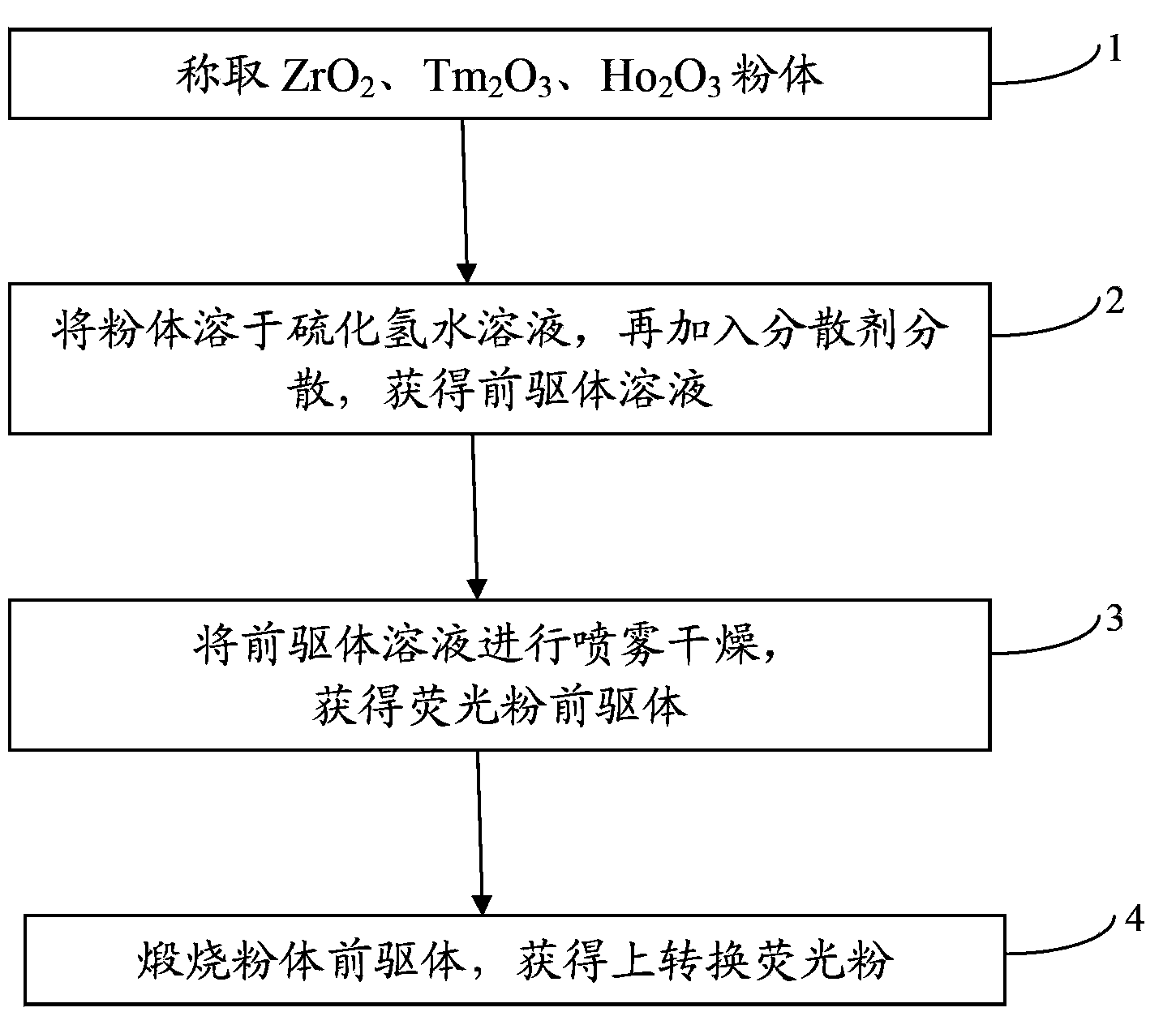

[0039] Combine figure 1 As shown in the flow chart of the preparation process of thulium-holmium co-doped zirconium disulfide upconversion phosphor, the present invention provides a method for preparing thulium-holmium co-doped zirconium disulfide upconversion phosphor, including the following steps:

[0040] (1) Weigh ZrO separately 2 (0.96mmol), Tm 2 O 3 (0.015mmol), Ho 2 O 3 (0.005mmol) powder;

[0041] (2) Dissolve the powder obtained in (1) in an aqueous solution containing 2.5 mmol hydrogen sulfide, then add an appropriate amount of polyethylene glycol with a concentration of 0.01 mol / L, and mix well to obtain a precursor solution. The ZrO 2 (0.96mmol), Tm 2 O 3 (0.015mmol) and Ho 2 O 3 (0.005mmol) The total concentration of the powder in the precursor solution is 1.5mol / L;

[0042] (3) Introduce the precursor solution obtained in (2) into the atomizer of the spray dryer, set the inlet temperature of the spray dryer to 180°C, the outlet temperature to 110°C, and pass argon at a ...

Embodiment 2

[0053] A preparation method of thulium-holmium co-doped zirconium disulfide up-conversion phosphor includes the following steps:

[0054] (1) Weigh ZrO separately 2 (0.90mmol), Tm 2 O 3 (0.03mmol), Ho 2 O 3 (0.02mmol) powder;

[0055] (2) Dissolve the powder obtained in (1) in an aqueous solution containing 3.5 mmol hydrogen sulfide to prepare a 3 mol / L mixed solution, then add an appropriate amount of polyethylene glycol with a concentration of 0.05 mol / L, and mix well to obtain Precursor solution, the ZrO 2 (0.90mmol), Tm 2 O 3 (0.03mmol) and Ho 2 O 3 (0.02mmol) The total concentration of the powder in the precursor solution is 3mol / L;

[0056] (3) Introduce the precursor solution obtained in (2) into the atomizer of the spray dryer, set the inlet temperature of the spray dryer to 220°C, the outlet temperature to 130°C, and pour argon at a gas flow rate of 15L / min. The precursor solution starts to be atomized into an aerosol, and enters the reaction system with the introduced gas,...

Embodiment 3

[0059] (1) Weigh ZrO separately 2 (0.996mmol), Tm 2 O 3 (0.001mmol), Ho 2 O 3 (0.001mmol) powder;

[0060] (2) Dissolve the powder obtained in (1) in an aqueous solution containing 4 mmol hydrogen sulfide, then add an appropriate amount of polyethylene glycol with a concentration of 0.005 mol / L, and mix well to obtain a precursor solution. The ZrO 2 (0.996mmol), Tm 2 O 3 (0.001mmol) and Ho 2 O 3 (0.001mmol) The total concentration of the powder in the precursor solution is 0.5mol / L;

[0061] (3) Introduce the precursor solution obtained in (2) into the atomizer of the spray dryer, set the inlet temperature of the spray dryer to 150°C, the outlet temperature to 100°C, and pass argon at a gas flow rate of 1L / min. The precursor solution starts to be atomized into an aerosol, and enters the reaction system with the introduced gas, and generates a phosphor precursor in the reaction system;

[0062] (4) A microporous acid-resistant filter funnel is used to collect the phosphor precursors g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com