Method for performing oxide in-situ coating on zirconium diboride-silicon carbide aggregate powder

A zirconium diboride and in-situ coating technology, which is applied in the field of preparation of zirconium diboride-silicon carbide core-shell structure powder, can solve the problems of loose structure, powder easily broken, difficult to melt, etc., and achieve high density Sex, improve cohesion, improve the effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Add 75g of zirconium diboride, 25g of silicon carbide, 0.8g of PVA and 100g of absolute ethanol into a ball mill tank with a ball-to-material ratio of 4:1, and ball mill for 6 hours at 100r / min to mix the ingredients evenly. Obtain the suspension of precursor powder;

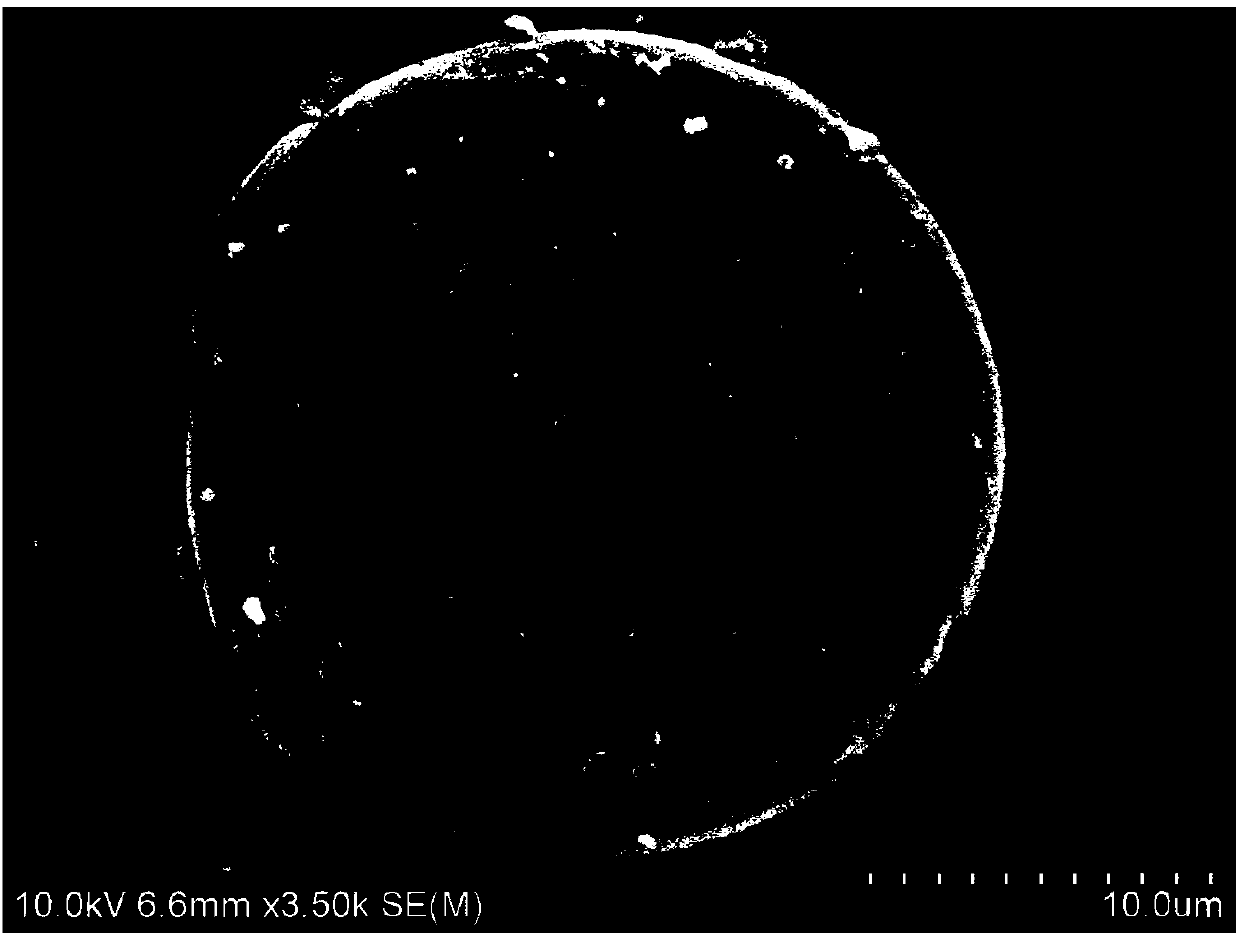

[0036] (2) Transfer the suspension obtained in step (1) to a spray drying granulation tower for agglomeration and granulation. The granulated powder is first dried in an oven at 80°C for 30 hours, and then passed through a test sieve to obtain granules. ZrB with a diameter of 20 μm to 90 μm 2 - SiC agglomerated powder;

[0037] Among them, the spray drying granulation parameters are: inlet temperature 210°C, outlet temperature 100°C, nozzle speed 25Hz, peristaltic pump speed 35rpm;

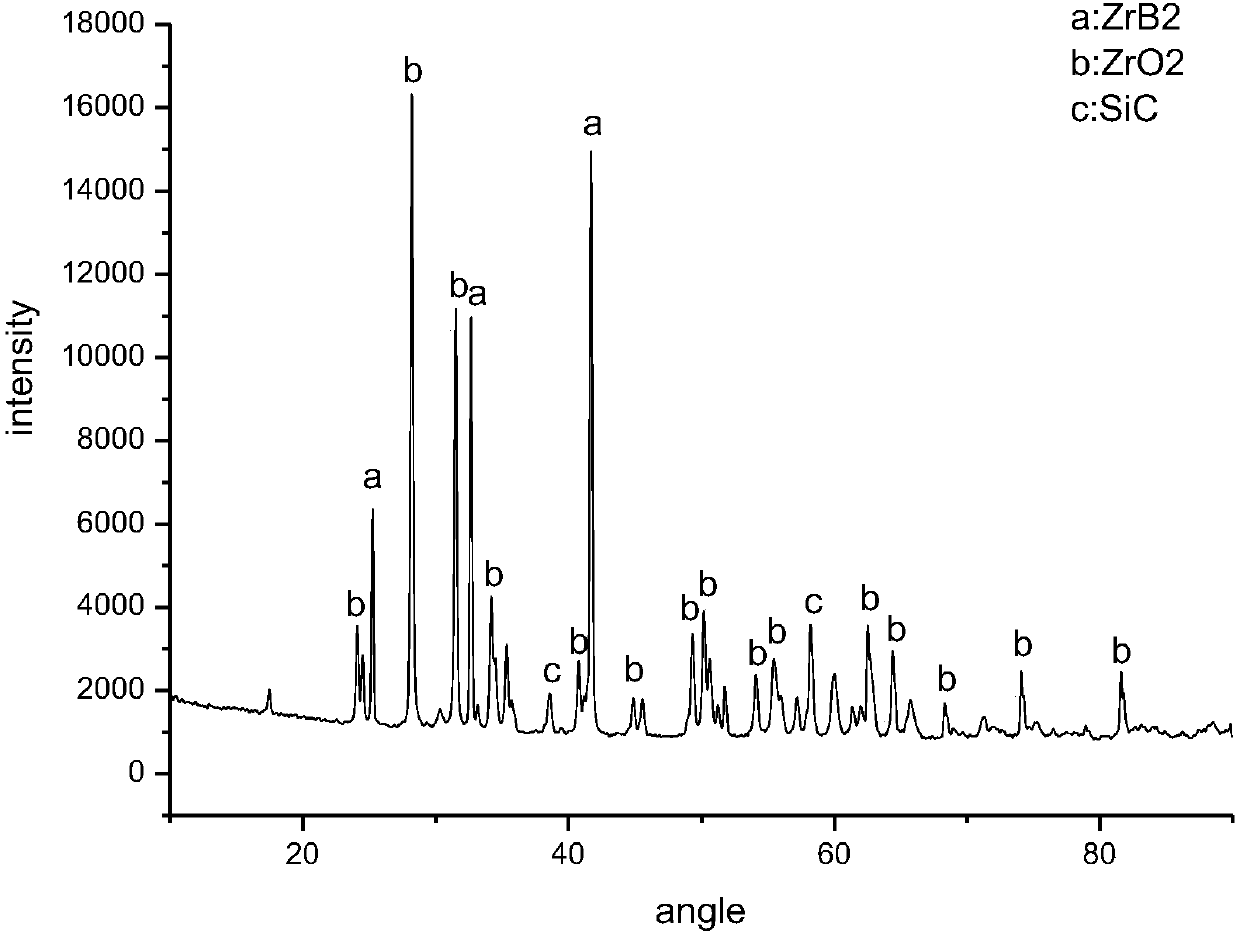

[0038] (3) ZrB obtained in step (2) 2 -SiC agglomerated powder is sent to the atmospheric plasma spheroidization equipment for spheroidization treatment, the spheroidized powder is collected by deionized water, and the...

Embodiment 2

[0045] (1) Add 80g of zirconium diboride, 20g of silicon carbide, 0.7g of PVA and 100g of absolute ethanol into a ball mill tank with a ball-to-material ratio of 4:1, and ball mill for 2 hours at 400r / min to mix the ingredients evenly. Obtain the suspension of precursor powder;

[0046] (2) Transfer the suspension obtained in step (1) to a spray drying granulation tower for agglomeration and granulation. The granulated powder is first dried in an oven at 150°C for 20 hours, and then passed through a test sieve to obtain granules. ZrB with a diameter of 20 μm to 90 μm 2 - SiC agglomerated powder;

[0047] Among them, the spray drying granulation parameters are: inlet temperature 350°C, outlet temperature 130°C, nozzle speed 45Hz, peristaltic pump speed 50rpm;

[0048] (3) ZrB obtained in step (2) 2 -SiC agglomerated powder is sent to the atmospheric plasma spheroidization equipment for spheroidization treatment, the spheroidized powder is collected by deionized water, and th...

Embodiment 3

[0053] (1) Add 82g of zirconium diboride, 18g of silicon carbide, 0.9g of PVA and 100g of absolute ethanol into a ball mill tank with a ball-to-material ratio of 4:1, and ball mill for 4 hours at 300r / min to mix the ingredients evenly. Obtain the suspension of precursor powder;

[0054] (2) Transfer the suspension obtained in step (1) to a spray drying granulation tower for agglomeration and granulation. The granulated powder is first dried in an oven at 120°C for 25 hours, and then passed through a test sieve to obtain granules. ZrB with a diameter of 20 μm to 90 μm 2 - SiC agglomerated powder;

[0055] Among them, the spray drying granulation parameters are: inlet temperature 270°C, outlet temperature 120°C, nozzle speed 30Hz, peristaltic pump speed 40rpm;

[0056] (3) ZrB obtained in step (2) 2 -SiC agglomerated powder is sent to the atmospheric plasma spheroidization equipment for spheroidization treatment, the spheroidized powder is collected by deionized water, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com