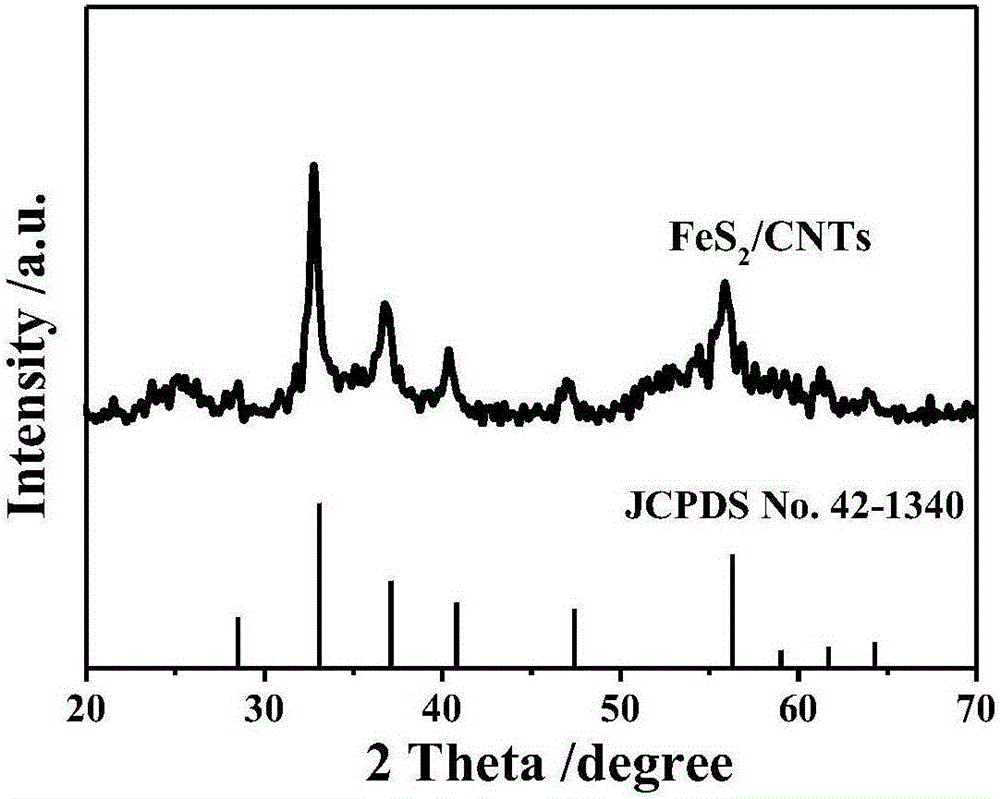

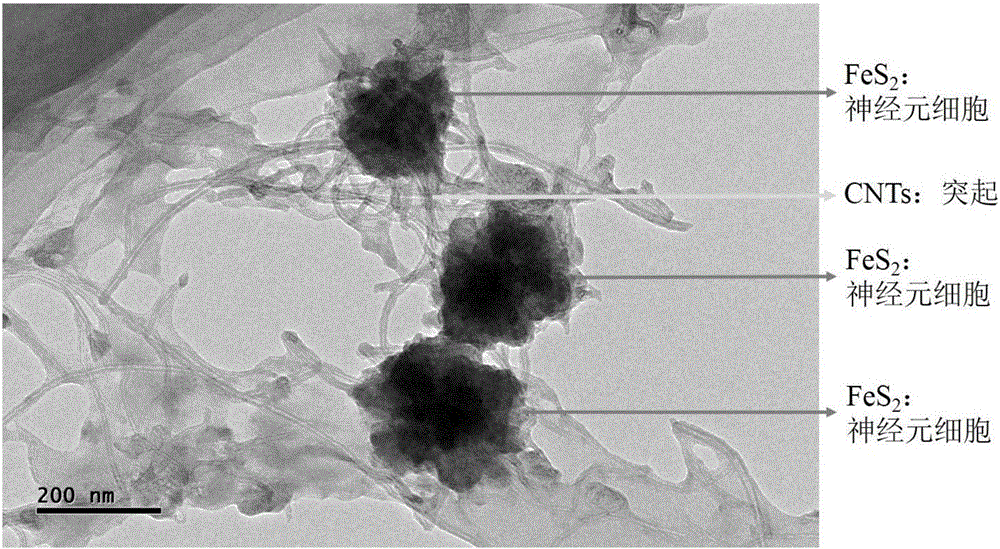

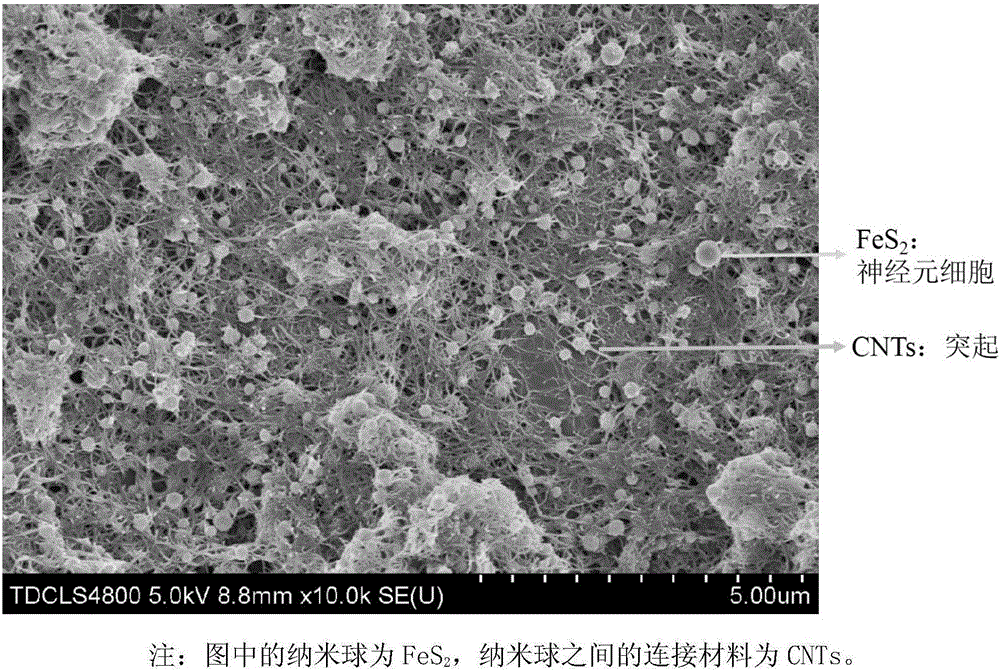

Iron disulfide/carbon nano tube composite material of neural network structure and preparation method thereof

A carbon nanotube and iron disulfide technology, which is applied in the field of inorganic nanomaterial synthesis, can solve the problems of not alleviating the volume expansion of iron disulfide and the large size of iron disulfide, and achieves improved cycle performance, improved wettability, and improved electrical conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1). Add 1.2g of carbon nanotubes to a mixed solution containing 400ml of ethylene glycol and 200ml of N,N-dimethylformamide, and ultrasonically for 0.5h to obtain a mixed solution in which carbon nanotubes are uniformly dispersed. Nanotube concentration is 2g / L;

[0031]2). Add 6g of ferrous sulfate to the uniformly dispersed mixed solution of carbon nanotubes prepared in step 1), stir at 200r / min for 10min, add 4g of sublimed sulfur and 6g of urea, and continue to stir at 200r / min for 1h. Prepare a mixed solution containing carbon nanotubes, iron salts and sulfur;

[0032] 3). Insulate the mixed solution containing carbon nanotubes, iron salt and sulfur prepared in step 2) at 170° C. for 48 hours;

[0033] 4). The hydrothermal product was repeatedly washed 6 times with deionized water and ethanol to remove impurities, and vacuum-dried at 110° C. for 12 hours to obtain an iron disulfide / carbon nanotube composite material with a neural network structure.

[0034] Such ...

Embodiment 2

[0036] 1). Add 4g of carbon nanotubes to a mixed solution containing 400ml of ethylene glycol and 400ml of N,N-dimethylformamide, and ultrasonically for 1 hour to obtain a mixed solution in which carbon nanotubes are uniformly dispersed. In the mixed solution, carbon nanotubes The concentration is 5g / L;

[0037] 2). Add 5g of ferrous sulfate to the uniformly dispersed mixture of carbon nanotubes prepared in step 1), stir at 300r / min for 20min, add 3.33g of sublimed sulfur and 6.66g of urea, and continue stirring at 300r / min After 0.5h, a mixed solution containing carbon nanotubes, iron salts and sulfur was obtained;

[0038] 3). Insulate the mixed solution containing carbon nanotubes, iron salt and sulfur prepared in step 2) at 190° C. for 24 hours;

[0039] 4). The hydrothermal product was repeatedly washed with deionized water and ethanol 8 times to remove impurities, and vacuum-dried at 100°C for 10 hours to obtain an iron disulfide / carbon nanotube composite material with ...

Embodiment 3

[0042] 1). Add 3.5g of carbon nanotubes to a mixed solution containing 300ml of ethylene glycol and 200ml of N,N-dimethylformamide, and ultrasonically for 1 hour to obtain a mixed solution in which carbon nanotubes are uniformly dispersed. In the mixed solution, carbon nanotubes Tube concentration is 7g / L,;

[0043] 2). Add 3.5g of ferrous sulfate to the uniformly dispersed mixed solution of carbon nanotubes prepared in step 1), stir at 400r / min for 30min, add 2.33g of sublimed sulfur and 4.19g of urea, and continue to stir at 400r / min Stir for 1h to obtain a mixed solution containing carbon nanotubes, iron salts and sulfur;

[0044] 3). Insulate the mixed solution containing carbon nanotubes, iron salt and sulfur prepared in step 2) at 180° C. for 12 hours;

[0045] 4). The hydrothermal product was repeatedly washed with deionized water and ethanol 8 times to remove impurities, and vacuum-dried at 60° C. for 12 hours to obtain an iron disulfide / carbon nanotube composite mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com