Method for preparing zirconium oxide powder by hydrothermal method using solid waste zirconium as raw material

A technology of zirconia powder and raw material water, which is applied in the field of zirconia powder preparation by hydrothermal method, can solve the problems of "three wastes" pollution, unfavorable environmental protection, etc., and achieve the effect of simple process, avoiding disposal problems, and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

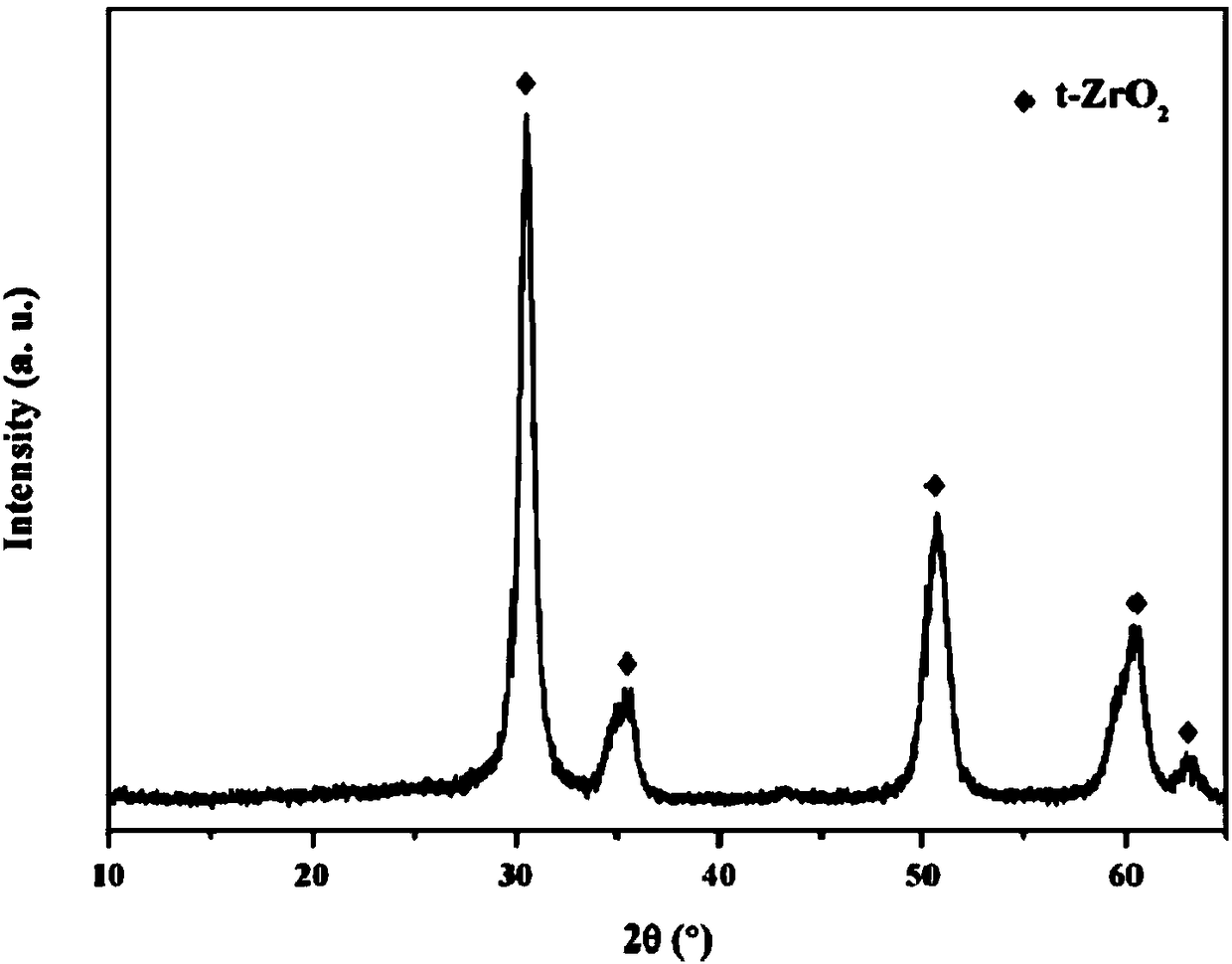

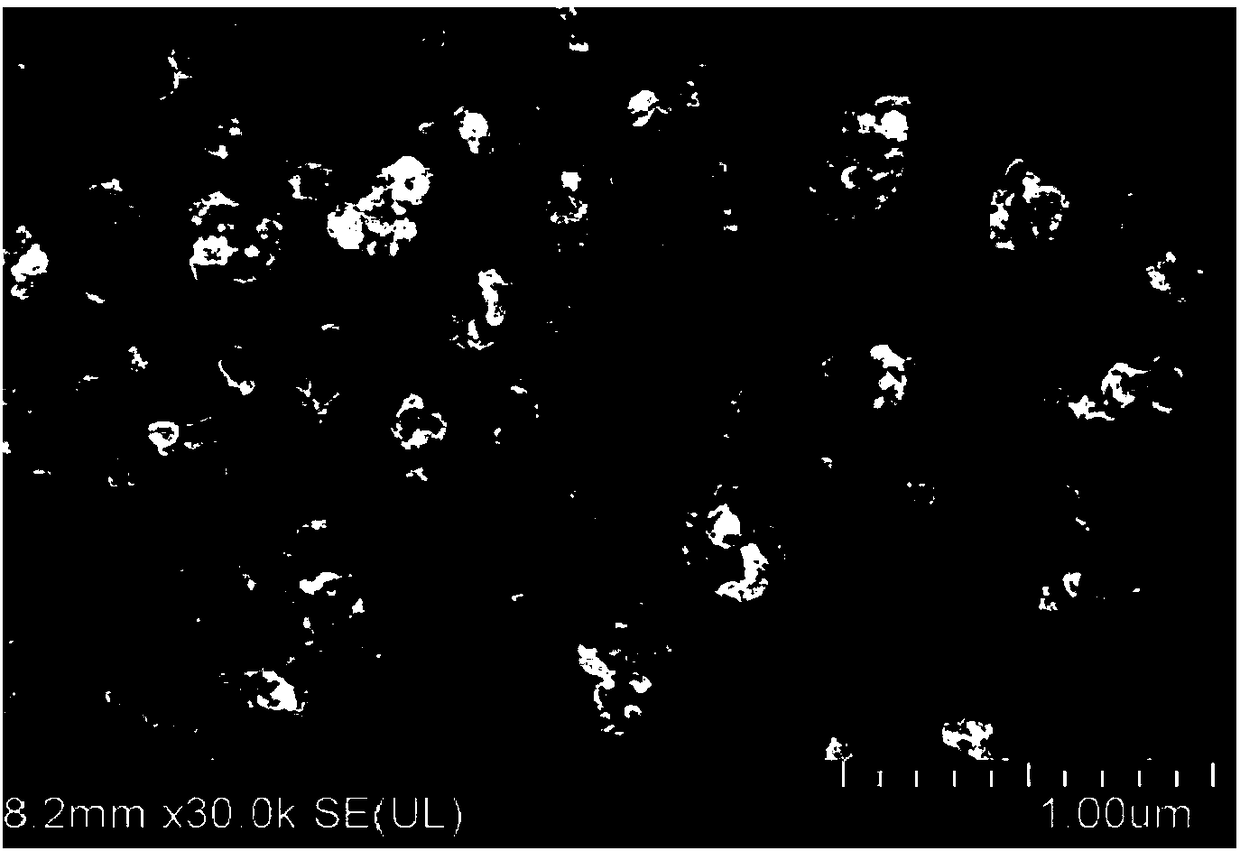

Image

Examples

Embodiment 1

[0036] Grind the waste zirconia ceramics into fine pieces, with an average particle size of 40nm, add caustic soda, the mass ratio of zirconia ceramics wastes to caustic soda is 1:1.2, mix them evenly, move them into a stainless steel pot, and roast at 800°C for 3 hours to obtain zirconium Salt;

[0037] Wash the zirconium salt with deionized water for 3 times, add hydrochloric acid solution for transformation, the hydrochloric acid solution is prepared from concentrated hydrochloric acid and water at a volume ratio of 1:1, the mass ratio of zirconium salt to hydrochloric acid solution is 1:2, and heat to 70°C for 3 hour, filter and remove the filter residue to obtain transformation liquid, the mass ratio of transformation liquid and sulfuric acid solution is 1:2.5, transformation liquid first reacts with the sulfuric acid solution of 1 / 2 quality, centrifuges to obtain basic zirconium sulfate, basic zirconium sulfate is further mixed with remaining Sulfuric acid solution react...

Embodiment 2

[0041] Grind zirconium diamond scraps into fine pieces, with an average particle size of 60nm, add caustic soda, the mass ratio of zirconia ceramic waste to caustic soda is 1:1.1, mix evenly, transfer to a stainless steel pot, and roast at 700°C for 4 hours to obtain zirconium salt ;

[0042]Wash the zirconium salt with deionized water for 3 times, add hydrochloric acid solution for transformation, the hydrochloric acid solution is prepared from concentrated hydrochloric acid and water at a volume ratio of 1:1, the mass ratio of zirconium salt to hydrochloric acid solution is 1:2.5, and heat to 60°C for reaction 4 hour, filter and remove the filter residue to obtain transformation liquid, the mass ratio of transformation liquid and sulfuric acid solution is 1:1.5, transformation liquid first reacts with the sulfuric acid solution of 1 / 2 quality, centrifuges to obtain basic zirconium sulfate, basic zirconium sulfate is further mixed with remaining Sulfuric acid solution reacts,...

Embodiment 3

[0046] Grind the zirconia refractory waste products into fine pieces, with an average particle size of 50nm, add caustic soda, the mass ratio of zirconia ceramic waste products to caustic soda is 1:1.5, mix them evenly, move them into a stainless steel pot, and roast them at 1000°C for 3 hours to obtain Zirconium salt;

[0047] Wash the zirconium salt with deionized water for 3 times, add hydrochloric acid solution for transformation, the hydrochloric acid solution is prepared from concentrated hydrochloric acid and water according to the volume ratio of 1:1, the mass ratio of zirconium salt to hydrochloric acid solution is 1:3, and heat to 80°C for reaction 2 hour, filter and remove the filter residue to obtain transformation liquid, the mass ratio of transformation liquid and sulfuric acid solution is 1:2, transformation liquid first reacts with the sulfuric acid solution of 1 / 2 quality, centrifuges to obtain basic zirconium sulfate, basic zirconium sulfate is further mixed w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com