Preparation method for ZrS2 two-dimensional semi-conducting material

A two-dimensional semiconductor, inert gas technology, applied in chemical instruments and methods, inorganic chemistry, zirconium compounds, etc., can solve the problems of high melting point, unsuitable raw materials, difficult sublimation, etc., achieves good crystallinity, convenient operation, and is conducive to The effect of commercial promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

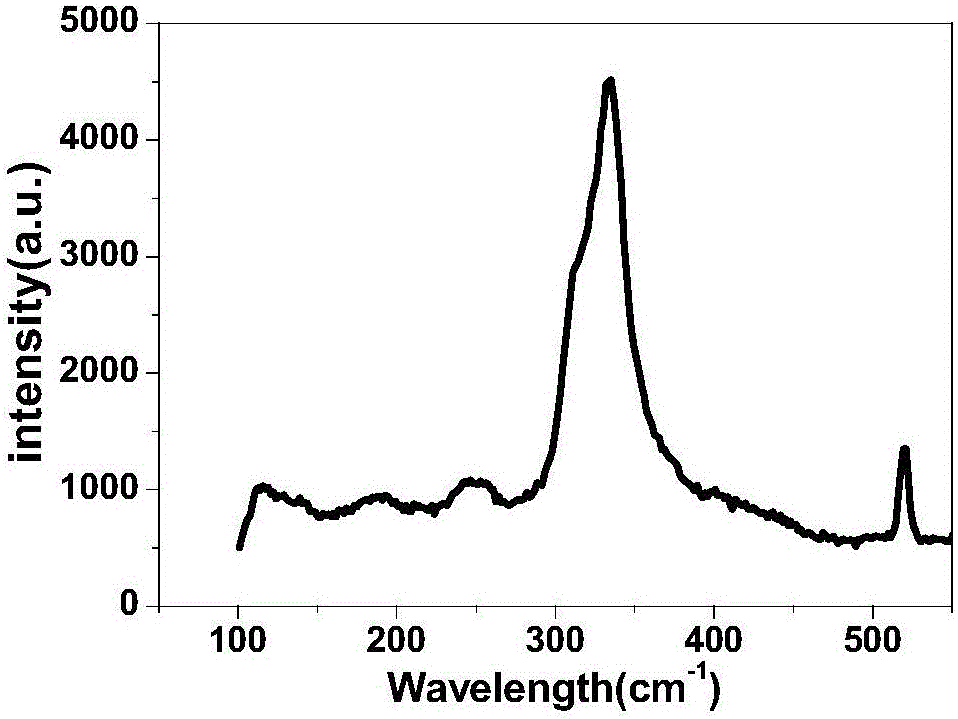

Image

Examples

Embodiment 1

[0019] Embodiment 1: a kind of ZrS 2 The preparation method of two-dimensional semiconductor material is characterized in that it comprises the following steps:

[0020] Step a. Place two pieces of SiO with the same size and face up on the quartz boat A. 2 / Si substrate, and then the quartz boat A with SiO 2 Put the / Si substrate together in the high-temperature tube furnace, and place the quartz boat A in the middle of the quartz tube of the high-temperature tube furnace;

[0021] Step b, spread the zirconium chloride powder in the quartz boat B, place it in the quartz tube of the high temperature tube furnace and place it at a distance of 12-15cm from the quartz boat A;

[0022] Step c, put the sulfur boat at a distance of 18-21cm from the quartz boat A, and place the sulfur boat and the quartz boat B on one side of the quartz boat A;

[0023] Step d. Pass the inert gas into the quartz tube at room temperature for 8-15 minutes, completely exhaust the air in the quartz tub...

Embodiment 2

[0025] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in this embodiment, SiO is also included in step a 2 The cleaning of / Si substrate; Described cleaning is to use acetone, ethanol and deionized water at first to SiO 2 / Si substrate ultrasonic 10-15min, and then SiO 2 / Si substrate into H 2 o 2 and H 2 SO 4 Wash in the mixed solution for 2-3h, and finally wash with deionized water.

Embodiment 3

[0026] Embodiment 3: The difference between this embodiment and Embodiment 1 is that in this embodiment, the H 2 SO 4 and H 2 o 2 The volume ratio in the mixed solution is 3:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com