Dehydrogenation catalyst and preparation method thereof

A dehydrogenation catalyst, catalyst technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of easy aggregation of Pt, poor dispersion of Pt, etc., to reduce aggregation, activity and stability. The effect of improved performance and high propylene selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

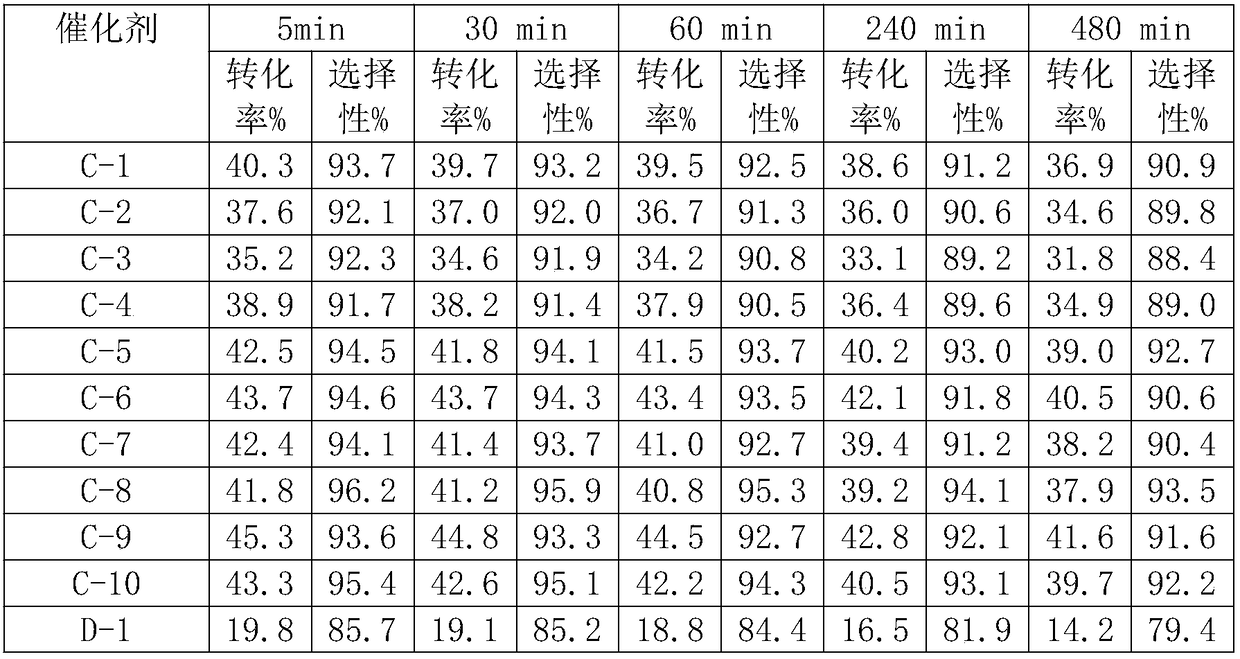

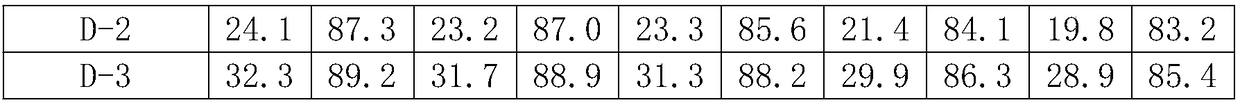

Examples

preparation example Construction

[0039] The invention provides a preparation method of a dehydrogenation catalyst, comprising: using Pt nano particle sol as an impregnating solution to impregnate a composite oxide carrier composed of zinc-modified zirconium dioxide and activated alumina.

[0040] Further, the method further includes the following steps: drying, calcining and reducing the impregnated composite oxide carrier composed of zinc-modified zirconia and activated alumina to obtain the dehydrogenation catalyst.

[0041] As a preferred version of the present invention, the dehydrogenation catalyst is obtained through the following preparation process steps, and the steps include:

[0042] (1) Preparation of Pt nanoparticle sol

[0043] a, add deionized water to dissolve in the required amount of surface stabilizer and co-active component compound, and make the surface stabilizer aqueous solution containing co-active component;

[0044] a. Mix the required amount of Pt-containing compound with the aqueous...

Embodiment 1

[0073] (1) Preparation of Pt nano-sol

[0074] Take 0.75g cetyltrimethylammonium bromide (CATB), dissolve it with 50.0mL deionized water, then pipette a certain amount (2.5mL0.10mol / L) of H 2 PtCl 6 The solution was added to the above CATB solution, and stirred at room temperature for 30-40min. Weigh a certain amount of 0.15gNaBH 4 Dissolve in 10mL deionized water to prepare NaBH 4 solution, NaBH was stirred vigorously 4 The solution was added dropwise to H 2 PtCl 6 In the mixed solution with CATB, the dropping rate is 60 drops / min (about 3ml / min), the dropping process is accompanied by a large number of bubbles, and the stirring is continued for 5 hours at room temperature, and the Pt nano-sol can be obtained.

[0075] (2) Carrier preparation

[0076] Add 3kg of deionized water into the stirred tank, start stirring and add 300g of pseudoboehmite powder, after stirring evenly, add zirconium oxychloride, so that the mass ratio of zirconium aluminum to ZrO 2 :Al 2 o 3 ...

Embodiment 2

[0081] (1) Preparation of Pt nano-sol

[0082] Take 0.75g cetyltrimethylammonium bromide (CATB), dissolve it with 50.0mL deionized water, then pipette a certain amount (2.5mL0.10mol / L) of H 2 PtCl 6 The solution was added to the above CATB solution, and stirred at room temperature for 30-40min. Weigh a certain amount of 0.15gNaBH 4 Dissolve in 10mL deionized water to prepare NaBH 4 solution, NaBH was stirred vigorously 4 The solution was added dropwise to H 2 PtCl 6 In the mixed solution with CATB, the dropping rate is 60 drops / min (about 3ml / min), the dropping process is accompanied by a large number of bubbles, and the stirring is continued for 5 hours at room temperature, and the Pt nano-sol can be obtained.

[0083] (2) Carrier preparation

[0084] Add 3kg of deionized water into the stirred tank, start stirring and add 300g of pseudoboehmite powder, after stirring evenly, add zirconium oxychloride, so that the mass ratio of zirconium aluminum to ZrO 2 :Al 2 o 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com