Gasoline hydrofining catalyst and preparation method thereof

A gasoline hydrogenation and catalyst technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problems of gasoline octane number drop, olefin oversaturation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

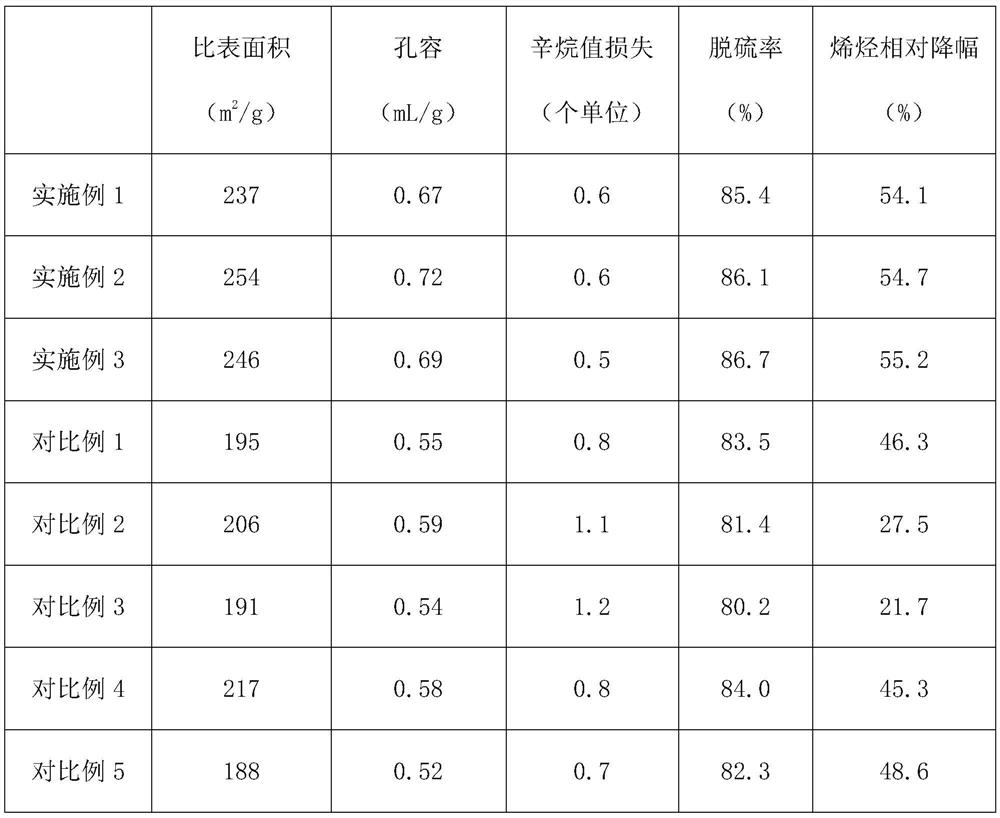

Examples

Embodiment 1

[0032] (1) Take pseudo-boehmite, add sodium hydroxide, deionized water, and 1,6-hexanediamine, stir and mix, add silica sol, stir for 30 minutes, and age for 18 hours to obtain the first solution;

[0033] Mix sodium metaaluminate and sodium hydroxide, add deionized water and sodium silicate solution, cool to 0°C, and cut for 25 minutes to prepare the second solution;

[0034] The first solution was slowly added to the second solution, sheared for 2 hours, and crystallized. The crystallization process was as follows: temperature 150°C, time 36 hours, washing to neutrality, and drying at 60°C to obtain carrier A. The ratio of silicon to aluminum in carrier A is 6.2;

[0035] (2) Take sulfur and add chloroform, heat, stir and dissolve, add coupling agent and carrier A, uniformly disperse, add nano-aluminum powder, and ultrasonically disperse;

[0036] Vacuum drying at a temperature of 90°C, passing through dry nitrogen, calcining at a temperature of 1000°C for 5 hours, washing ...

Embodiment 2

[0043] (1) Take pseudo-boehmite, add sodium hydroxide, deionized water, and 1,6-hexanediamine, stir and mix, add silica sol, stir for 35 minutes, and age for 21 hours to obtain the first solution;

[0044] Mix sodium metaaluminate and sodium hydroxide, add deionized water and sodium silicate solution, cool to 0°C, and cut for 30 minutes to prepare the second solution;

[0045] Slowly add the first solution to the second solution, shear for 2.5 hours, and crystallize. The crystallization process is as follows: temperature 155°C, time 42h, washing to neutrality, and drying at 105°C to obtain carrier A , the ratio of silicon to aluminum in carrier A is 7.8;

[0046] (2) Take sulfur and add chloroform, heat, stir and dissolve, add coupling agent and carrier A, uniformly disperse, add nano-aluminum powder, and ultrasonically disperse;

[0047] Vacuum drying at 105°C, passing through dry nitrogen, calcining at 1050°C for 8 hours, washing with water, and drying at 105°C to obtain carr...

Embodiment 3

[0054] (1) Take pseudo-boehmite, add sodium hydroxide, deionized water, and 1,6-hexanediamine, stir and mix, add silica sol, stir for 40 minutes, and age for 24 hours to obtain the first solution;

[0055] Mix sodium metaaluminate and sodium hydroxide, add deionized water and sodium silicate solution, cool to 0°C, and cut for 35 minutes to prepare the second solution;

[0056] Slowly add the first solution to the second solution, shear for 3 hours, and crystallize. The crystallization process is as follows: temperature 160°C, time 48h, washing to neutrality, and drying at 120°C to obtain carrier A. The ratio of silicon to aluminum in carrier A is 9.4;

[0057] (2) Take sulfur and add chloroform, heat, stir and dissolve, add coupling agent and carrier A, uniformly disperse, add nano-aluminum powder, and ultrasonically disperse;

[0058] Vacuum drying at 120°C, passing through dry nitrogen, calcining at 1100°C for 12 hours, washing with water, and drying at 120°C to obtain carr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com