Antibacterial polymer and material prepared therefrom and use thereof

A polymer and antibacterial agent technology, applied in the field of antibacterial polymers, can solve the problems of premature release peak, weak binding force, inconvenient use, etc., and achieve the effect of safe synthesis and easy synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

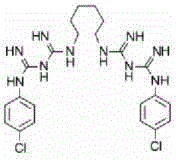

Method used

Image

Examples

Embodiment 1

[0037] The polyurethane containing chlorhexidine is prepared through the following steps:

[0038] A. In the reactor, heat and melt PCL at 70°C under vacuum ( 300g ) , keep for 3 hours;

[0039] B. After cooling down to 65°C, add DMSO (180ml), THDL (31.54g) and catalyst Bi348 ( 12.5g ) , maintaining a heating temperature of 65°C under a nitrogen-protected environment, and continuously stirring for 4 hours;

[0040] C. the DMSO solution of chlorhexidine (0.37g / ml, total 120ml DMSO ) Add it into the reactor and keep stirring at a temperature of 65°C for 17 hours;

[0041] D. Add methanol to the reactor (50ml, the ratio is 1ml methanol per 0.17g PCL ) , stirred at 65°C for 1 hour;

[0042] E. After the liquid in the reactor is cooled to room temperature, add dropwise in ether (2000ml), stir;

[0043] F. Heat-dissolve the polymer in the reactor in isopropanol (100~150ml), then add 300ml of EDTA solution (preparation method: dissolve 50g EDTA into 800ml deionized water, add...

Embodiment 2

[0049] The polyurethane containing chlorhexidine gluconate is prepared through the following steps:

[0050] A. In the reactor, heat and melt PCL300g at 70°C under vacuum environment, and keep it for 2 hours;

[0051] B. After cooling down to 60°C, add DMSO (180ml), THDL (31.54g) and catalyst Bi348 (12.5g) into the reactor under nitrogen atmosphere, keep the heating temperature at 60°C under nitrogen protection, and keep stirring 4 hours;

[0052] C. Add the DMSO (120ml) solution of 44.89g of chlorhexidine gluconate into the reactor, and keep stirring at a temperature of 60°C for 12 hours

[0053] D. add methanol (50ml) in the reactor, stir at 60 ℃ for 1 hour;

[0054] E. After the liquid in the reactor is cooled to room temperature, add dropwise in ether (2000ml), stir;

[0055] F. Heat the polymer in the reactor into isopropanol (100-150ml), then add 300ml of EDTA solution (see Example 1 for the configuration method), add 3000ml of deionized water after the reaction, and ...

Embodiment 3

[0061] The polyurethane containing chlorhexidine gluconate is prepared through the following steps:

[0062] A. In the reactor, heat and melt PCL300g at 70°C under vacuum environment, and keep it for 2 hours;

[0063] B. keep at 70 ℃, add DMSO (180ml), THDL (31.54g) and catalyst Bi348 ( 12.5g ) , keep the heating temperature at 70° C. under the environment of nitrogen protection, and keep stirring for 4 hours.

[0064] C. the DMSO (120ml) solution of chlorhexidine gluconate 44.89g is added in the reactor, and the temperature of maintaining 70 ℃ was stirred for 30 hours;

[0065] D. Add 50ml of methanol to the reactor and stir at 70°C for 1 hour;

[0066] E. After cooling the liquid in the reactor to room temperature, add it dropwise into 3000ml of diethyl ether, and stir;

[0067] F. Heat-dissolve the polymer in the reactor in 100-150ml of isopropanol, then add 300ml of EDTA solution (see Example 1 for the configuration method), add 3000ml of deionized water after the reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com