Preparation method of three-dimensional TiO2 nanowire/MXene composite material

A composite material and nanowire technology, which is applied in the field of preparation of three-dimensional TiO2 nanowire/MXene composite materials, can solve the problems of easy oxidation of nanosheets, increased requirements for storage devices, and increased production costs, and achieves a high density that is conducive to tight penetration and ionization. The effect of fast transmission, good development and application prospects, and improved security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

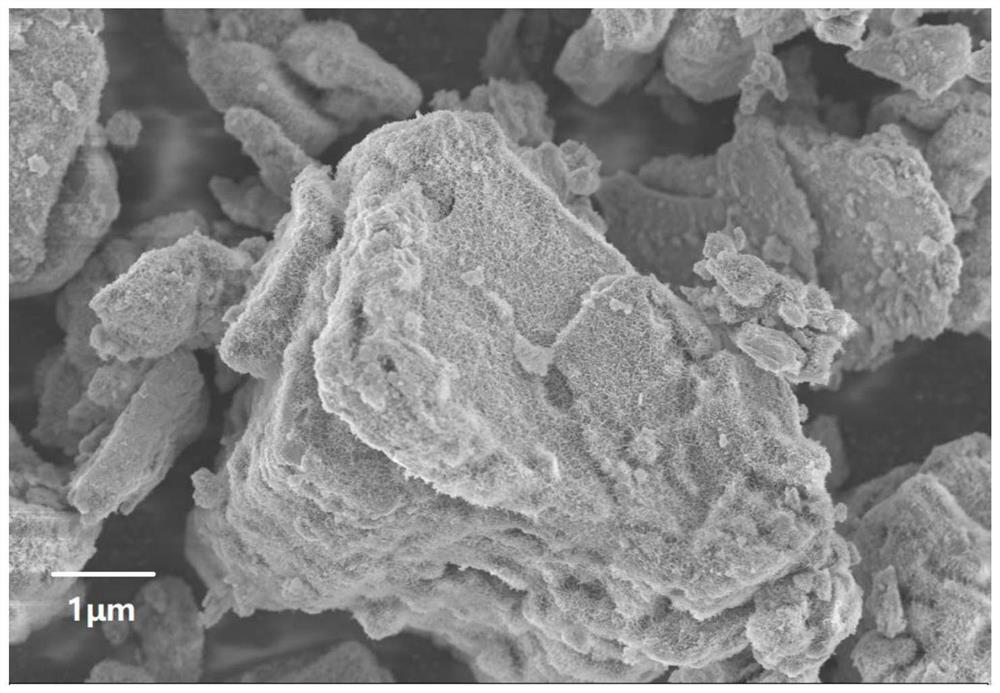

[0044] The 60 ml concentration of 5.49 mg / ml hydrochloric acid solution was taken with 3 g of fluorinated lithium fluoride in a plastic container for 15 min to dissolve hydrofluoric acid; 3 g of titanium aluminum aluminum aluminum 3 ALC 2 In the same temperature, it was slowly added to the above solution, etching 48h peeling the aluminum layer; the reaction solution was centrifuged 6 times, the top 5 centrifugal revolutions were 3500 rpm, the time was 5 min, and the last centrifugal revolution was 5000 rpm, and the time was 30 min. The freeze-dried temperature is provided below -5 ° C, the time is 60 h, the vacuum is 1 Pa, and the freeze drying is carried out in a freeze dryer. The cold trap temperature is set to -63 ° C to eliminate water vapor, and the freeze-drying is completed. Ti 3 C 2 Mxne; 50mg Ti 3 C 2 MXENE was dispersed at 15 ml of concentration of 40 g / L sodium hydroxide solution, then the magnetic force was stirred at 600 rpm of rotational speed for 120 h, and the ...

Embodiment 2

[0048] The 60 ml concentration of 5.49 mg / ml hydrochloric acid solution was taken with 3 g of fluorinated lithium fluoride in a plastic container for 15 min to dissolve hydrofluoric acid; 3 g of titanium aluminum aluminum aluminum 3 ALC 2 In the same temperature, it was slowly added to the above solution, etching 48h peeling the aluminum layer; the reaction solution was centrifuged 6 times, the top 5 centrifugal revolutions were 3500 rpm, the time was 5 min, and the last centrifugal revolution was 5000 rpm, and the time was 30 min. The freeze-dried temperature is set below -5 ° C, the time is 60 h, the vacuum is 1 Pa, and the freeze-drying is carried out in a freeze dryer. Ti 3 C 2 Mxne; 50mg Ti 3 C 2 MXENE was dispersed in a 15 ml concentration of 20 g / L in sodium hydroxide solution, then the magnetic force was stirred at 600 rpm to stir for 120 h, and the composite material was centrifuged at 8000 rpm for 8 min, 55 ° C, dried overnight, i.e., the product product was obtained...

Embodiment 3

[0052] The 60 ml concentration of 5.49 mg / ml hydrochloric acid solution was taken with 3 g of fluorinated lithium fluoride in a plastic container for 15 min to dissolve hydrofluoric acid; 3 g of titanium aluminum aluminum aluminum 3 ALC 2 In the same temperature, it was slowly added to the above solution, etching 48h peeling the aluminum layer; the reaction solution was centrifuged 6 times, the top 5 centrifugal revolutions were 3500 rpm, the time was 5 min, and the last centrifugal revolution was 5000 rpm, and the time was 30 min. The freeze-dried temperature is below -5 ° C, the time is 60 h, the vacuum is 1 Pa, and the freeze drying is carried out in a freeze dryer. The cold trap temperature is set to -63 ° C to eliminate water vapor, and the freeze-drying is completed. Ti 3 C 2 Mxne; 50mg Ti 3 C 2 MXENE was dispersed at 15 ml of concentration of 40 g / L sodium hydroxide solution, then the magnetic force was stirred at 600 rpm of rotational speed for 120 h, and the composite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com