Method for synthesizing super small-size CdSe nanocrystalline through one-pot process

A small-sized, nanocrystalline technology, applied in the fields of nanotechnology, nano-optics, nanotechnology, etc., can solve the problems of poor stability of ultra-small-sized nanocrystals, environmentally harmful phosphine compounds, single ultra-small nanocrystals, etc., and achieve nucleation. Stable and controllable growth rate, good operability and repeatability, and low synthesis cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

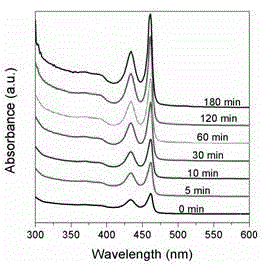

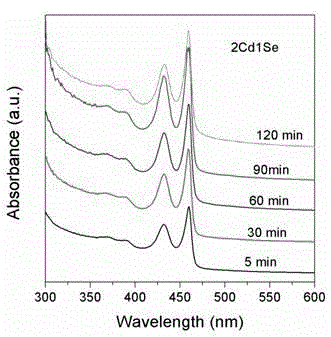

[0028] Example 1: Preparation of ultra-small size CdSe nanocrystalline F461 species

[0029] Mix 0.022g (0.2mmol) selenium dioxide and 2mL N-oleoyl morpholine, raise the temperature under magnetic stirring until the selenium dioxide is completely dissolved, and then cool to room temperature to obtain the Se precursor;

[0030] Mix 0.213g (0.8mmol) cadmium acetate dihydrate and 3mL N-oleoyl morpholine, stir and heat until the cadmium acetate dihydrate is completely dissolved, then cool to room temperature to obtain the Cd precursor;

[0031] Mix the above two solutions, heat under stirring, start timing at a heating rate of 15°C / min to 210°C, and take samples at different growth times, inject the taken samples into cold toluene, add methanol to precipitate out For the crude product of nanocrystals, the volume ratio of the added precipitant to the nanocrystal solution is 2:1, the crude product is then dissolved in toluene, the precipitant is precipitated, and centrifuged, and tr...

Embodiment 2

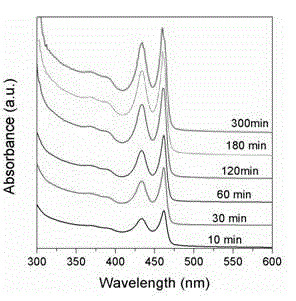

[0036] Embodiment 2: Preparation of ultra-small size CdSe nanocrystals emitting white light

[0037] Mix 0.022g (0.2mmol) of selenium dioxide and 2mL of N-oleoyl morpholine, raise the temperature under magnetic stirring until the selenium dioxide is completely dissolved, and then cool to room temperature to obtain the Se precursor;

[0038] Mix 0.213g (0.8mmol) cadmium acetate dihydrate, 0.200g (1mmol) lauric acid and 3mL N-oleoyl morpholine, stir and heat until the cadmium acetate dihydrate is completely dissolved, then cool to room temperature to obtain the Cd-lauric acid precursor ;

[0039] Mix the above two solutions, heat under stirring, start timing at a heating rate of 10°C / min to 150°C, and take samples at different growth times, inject the taken samples into cold toluene, add methanol to precipitate out For the crude product of nanocrystals, the volume ratio of the added precipitant to the nanocrystal solution is 2:1, the crude product is then dissolved in toluene, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com