Fluorescent molecularly imprinted polymer hollow microsphere and preparation method and application thereof

A technology of fluorescent molecular imprinting and hollow microspheres, which is applied in the direction of fluorescence/phosphorescence, alkali metal compounds, chemical instruments and methods, etc., can solve the problems of inability to quickly and efficiently detect specificity, unsafe synthesis process, and environmental protection, and achieve fast The effect of efficient synthesis process and shortened detection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Include the following steps:

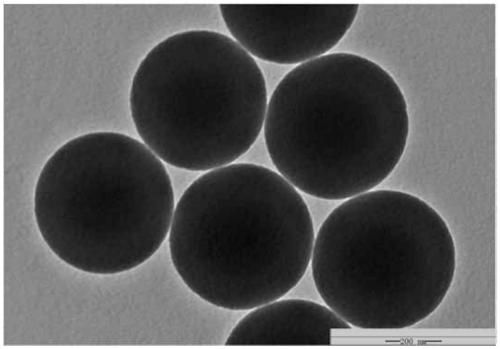

[0050] Step 1: Preparation of silica nanoparticles SiO 2

[0051] First, configure ethanol-deionized water mixed solution, add ammonia water to it, and obtain mixed solution A after ultrasonic treatment for 10 minutes; place mixed solution A at room temperature under magnetic stirring, and slowly add ethyl orthosilicate through a burette under the protection of an inert gas Ester TEOS was reacted until the solution changed from clear and transparent to milky white (obvious change occurred within about 20 minutes), continued to react for 6 hours, collected by centrifugation, washed repeatedly with ethanol-water solution and vacuum freeze-dried for 8 hours to obtain silica Nanoparticles; ammonia water: ethanol: water: tetraethyl orthosilicate is 2:25:25:2, magnetic stirring 600 rpm, centrifugal speed 10000rpm / min, time 10min,

[0052] Step 2: Preparation of silica surface grafted with fluorescein isothiocyanate SiO 2 Polymers by @FITC-APT...

Embodiment 2

[0060] Include the following steps:

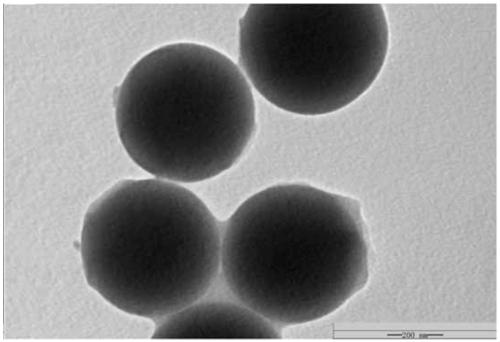

[0061] Step 1: Preparation of silica nanoparticles SiO 2

[0062] First, configure ethanol-deionized water mixed solution, add ammonia water to it, and obtain mixed solution A after ultrasonic treatment for 10 minutes; place mixed solution A at room temperature under magnetic stirring, and slowly add ethyl orthosilicate through a burette under the protection of an inert gas Ester TEOS was reacted until the solution changed from clear and transparent to milky white (obvious change occurred within about 20 minutes), continued to react for 6 hours, collected by centrifugation, washed repeatedly with ethanol-water solution and vacuum freeze-dried for 8 hours to obtain silica Nanoparticles; ammonia water: ethanol: water: tetraethyl orthosilicate is 2:25:25:2, magnetic stirring 600 rpm, centrifugal speed 10500rpm / min, 7.5min,

[0063] Step 2: Preparation of silica surface grafted with fluorescein isothiocyanate SiO 2 Polymers by @FITC-APTES; ...

Embodiment 3

[0071] Include the following steps:

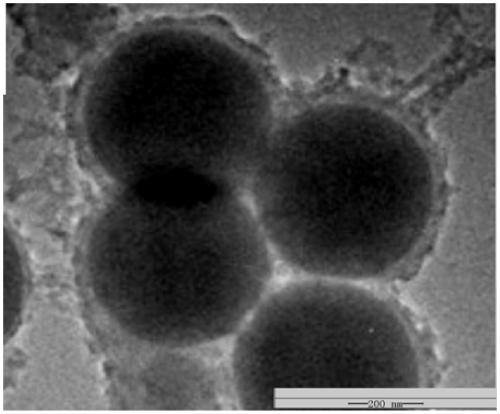

[0072] Step 1: Preparation of silica nanoparticles SiO 2

[0073] First, configure ethanol-deionized water mixed solution, add ammonia water to it, and obtain mixed solution A after ultrasonic treatment for 10 minutes; place mixed solution A at room temperature under magnetic stirring, and slowly add ethyl orthosilicate through a burette under the protection of an inert gas Ester TEOS was reacted until the solution changed from clear and transparent to milky white (obvious change occurred within about 20 minutes), continued to react for 6 hours, collected by centrifugation, washed repeatedly with ethanol-water solution and vacuum freeze-dried for 8 hours to obtain silica Nanoparticles; ammonia water: ethanol: water: tetraethyl orthosilicate 2:25:25:2, magnetic stirring 600 rpm, centrifugal speed 11000 rpm / min, 5 min;

[0074] Step 2: Preparation of silica surface grafted with fluorescein isothiocyanate SiO 2 Polymers by @FITC-APTES;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com