Fischer-Tropsch synthesis iron-based catalyst and preparation method thereof

An iron-based catalyst and Fischer-Tropsch synthesis technology, applied in catalyst activation/preparation, chemical instruments and methods, preparation of liquid hydrocarbon mixtures, etc., can solve the complex manufacturing process of Fischer-Tropsch synthesis iron-based catalysts, etc., to improve the utilization of atoms High efficiency, good stability, and the effect of saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

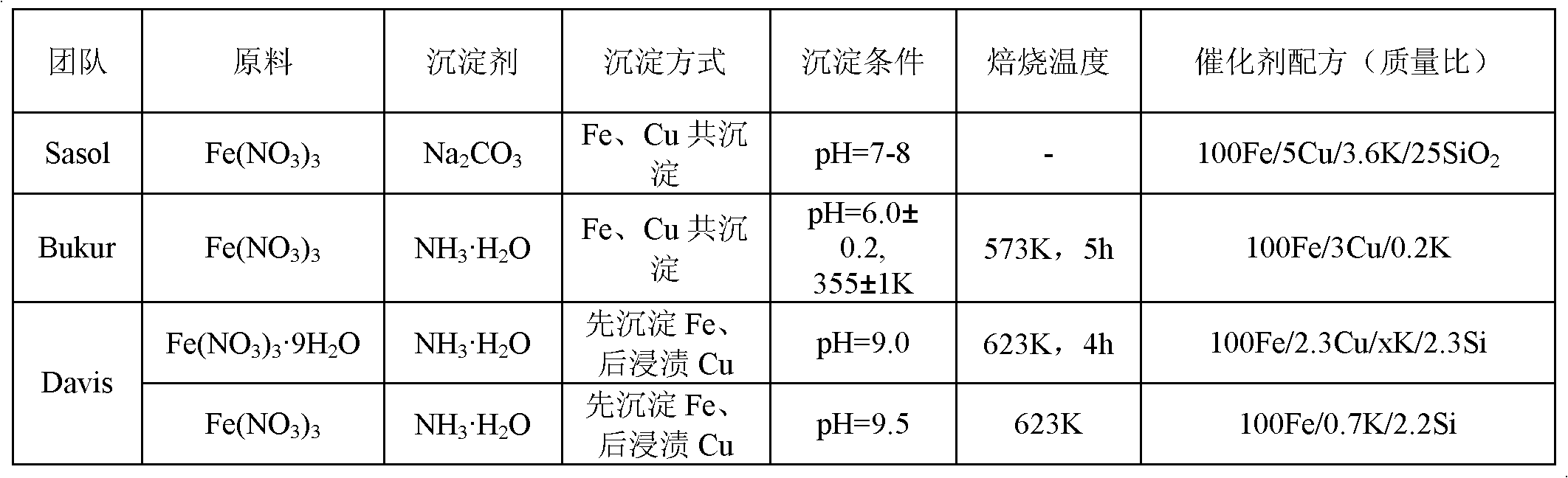

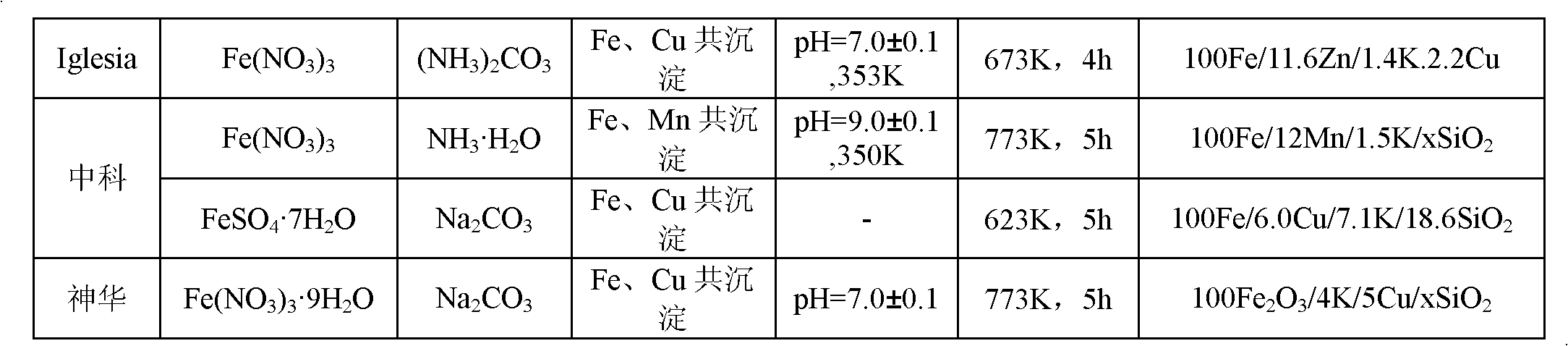

[0021] According to a typical embodiment of the present invention, the preparation method of the Fischer-Tropsch synthesis iron-based catalyst comprises the following steps: 1) co-precipitating the aqueous solution of iron salt, copper salt, cobalt salt and potassium carbonate aqueous solution to obtain a precipitation slurry; 2 ) After the precipitation slurry is aged, add water and stir evenly, then concentrate to remove part of the water; 3) Add potassium silicate water glass or silica sol to the concentrated precipitation slurry, stir evenly, and let it stand for 0-180 Minutes; 4) Step 3) After the slurry obtained in step 3) was spray-dried and roasted, an iron-based catalyst for Fischer-Tropsch synthesis was obtained, wherein the addition of iron salt, copper salt, cobalt salt, potassium carbonate, potassium silicate water glass and silica sol The amount makes the generated catalyst include the following mass ratio of the component Fe 2 o 3 : Cu: K: SiO 2 :Co=100:(1-10)...

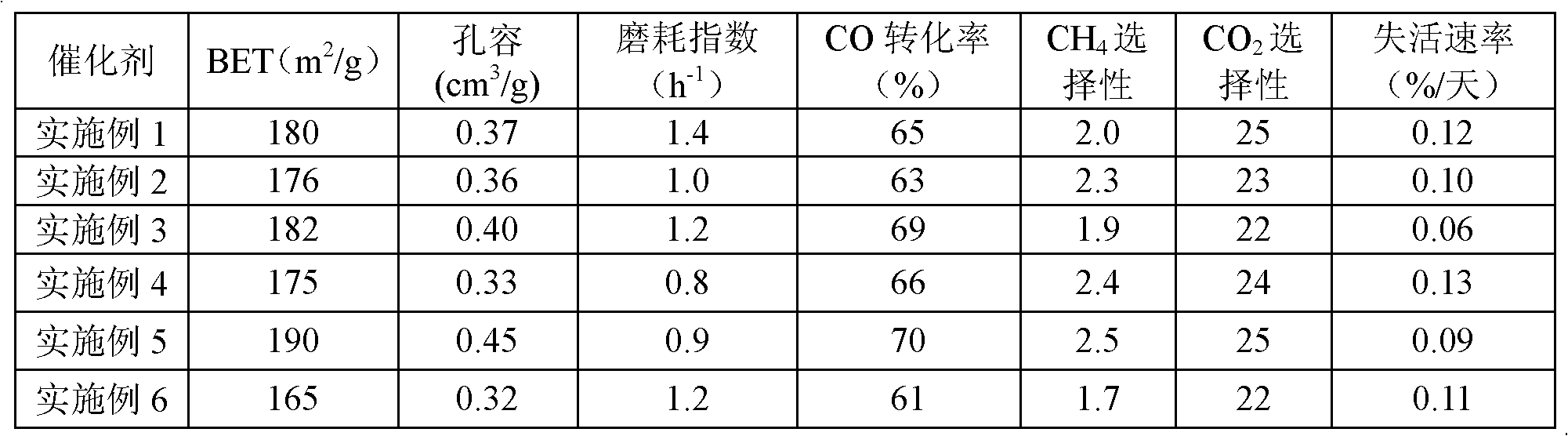

Embodiment 1

[0029] 25kg ferric nitrate nonahydrate, 0.7kg copper nitrate, 4.5kg cobalt nitrate hexahydrate are dissolved in deionized water, are made into 160 liters of solutions (solution mass concentration is 18.88wt%), 12.5kg salt of wormwood is dissolved with deionized water, Make 80 liters of solutions (solution mass concentration is 15.63wt%). Use a pump to flow ferric nitrate, copper nitrate, cobalt nitrate solution and potassium carbonate solution into the reaction kettle, control the temperature in the reaction kettle at 60°C, and control the pH value at 6. After the precipitation is completed, let it stand for aging for 30 minutes. At 60°C, then add 80 liters of deionized water to the slurry (precipitation of Fe in the slurry 2 o 3 Concentration is 1.55%), after concentrating, make Fe in slurry 2 o 3 The concentration is 20wt%. rejoin K 2 O: SiO 2 =1.5 (mass ratio), in potassium silicate water glass, wherein the silicon dioxide concentration is 15%. After mixing evenly, let...

Embodiment 2

[0031] 25kg ferric nitrate nonahydrate, 0.40kg copper nitrate, 2kg cobalt nitrate hexahydrate are dissolved in deionized water, are made into 160 liters of solutions (solution mass concentration is 17.13wt%), 12.5kg salt of wormwood is dissolved with deionized water, prepare Become 100 liters of solutions (solution mass concentration is 12.50wt%). Use a pump to flow ferric nitrate, copper nitrate, cobalt nitrate solution and potassium carbonate solution into the reaction kettle, control the temperature in the reaction kettle at 70°C, and control the pH value at 7. After the precipitation is completed, stir and age for 30 minutes, and the temperature is controlled at 70°C, then add 200 liters of deionized water to the slurry (Fe in the precipitation slurry 2 o 3 Concentration is 1.01%), after concentrating, make Fe in slurry 2 o 3 The concentration is 8wt%. rejoin K 2 O: SiO 2 =1.5 (mass ratio), in the potassium silicate water glass, the silicon dioxide concentration is 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com