Method for synthesizing core-shell type zeolite molecular sieve

A technology of zeolite molecular sieve and synthesis method, applied in molecular sieve catalysts, chemical instruments and methods, crystalline aluminosilicate zeolite, etc., can solve the problems of expensive raw materials, large environmental pollution of template agents, and difficulty in industrial scale-up production, and reduce side effects. Reaction, improved selectivity and stability, effect of high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 15 milliliters of ethylamine, 210 grams of water glass (containing SiO 2 25.8 wt%, Na 2 O 7.3% by weight), 9.7 g of aluminum sulfate and 650 g of water were mixed, stirred for 1 hour, and then 25 g of SiO 2 / Al 2 o 3 25 ZSM-5 nuclear phase molecular sieve, the pH of the synthesis solution is 9.2, vigorously stirred for 3 hours, put into a 1000 ml stainless steel crystallization kettle, sealed, heated to 150°C, and crystallized at constant temperature for 3 days. At the end of the crystallization, quench the solid product, filter, wash, and dry overnight at 110°C to obtain the core-shell molecular sieve CS2, and the shell SiO 2 / Al 2 o 3 After analysis, it is found that it is 80, and the core-shell ratio is 95 / 5. The XRD analysis results are consistent with the literature data.

[0028] After ion-exchanging the core-shell molecular sieve CS2 according to the method described in Comparative Example 1, the core-shell molecular sieve CS2 and SiO 2 Binder mixed, stirr...

Embodiment 2~10

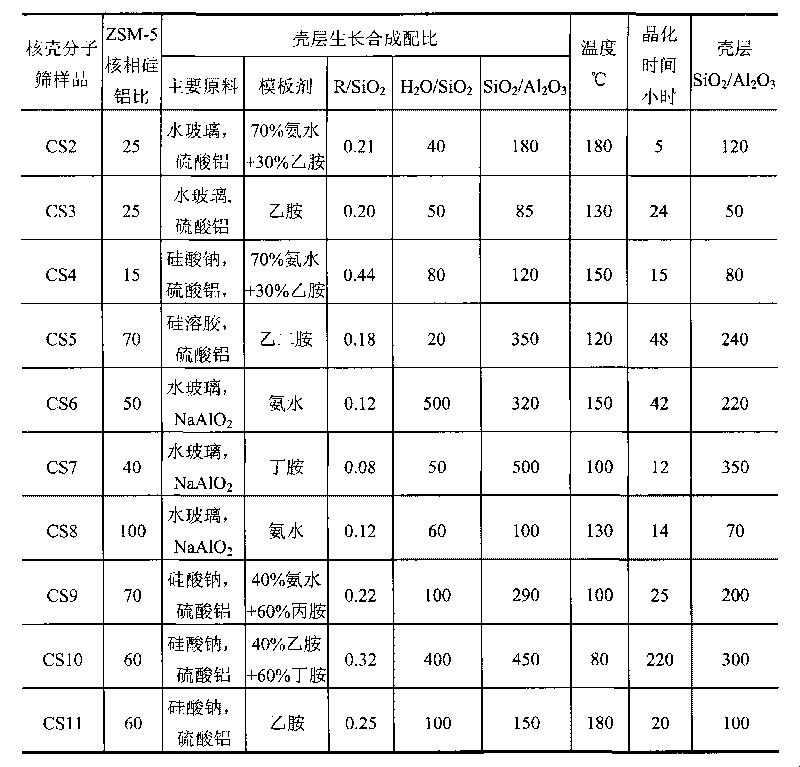

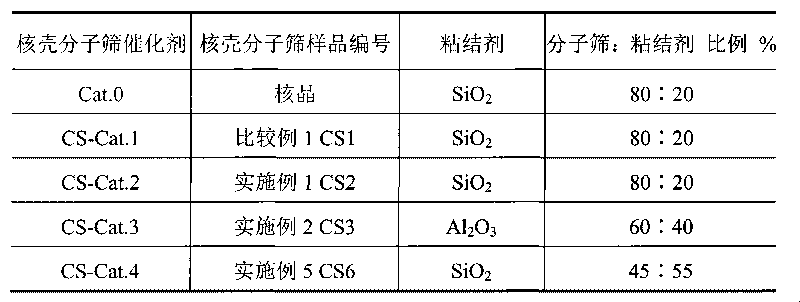

[0030] Examples 2-10 are based on the synthesis ratio and synthesis conditions in Table 1, and the core-shell molecular sieves CS3-12# are synthesized according to the similar method and steps of Embodiment 1, and the core crystal catalyst Cat.0 is prepared according to the similar method of Example 1. and core-shell molecular sieve catalysts CS-Cat1~4#, see Table 2 for details.

[0031] Table 1 Preparation conditions of core-shell molecular sieves

[0032]

[0033] Table 2 Core-shell catalyst preparation conditions

[0034]

Embodiment 11

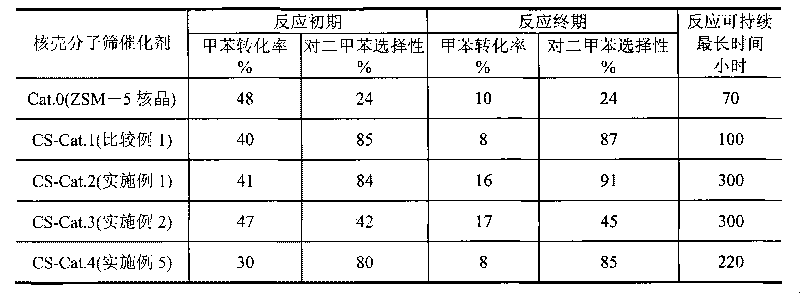

[0036] Use 2 grams of catalyst to evaluate toluene methanol selective alkylation reaction performance on a fixed bed continuous micro-reactor: the reaction raw material is a toluene methanol mixed solution (toluene methanol molar ratio is 2), and under the condition of hydrogen in the gas phase, the reaction pressure is 0.5 MPa, reaction temperature 420°C, feed liquid volume space velocity 4 hours -1 1. Under the condition that the hydrogen-to-hydrocarbon ratio is 3, the toluene conversion rate and p-xylene selectivity were measured by sampling and analysis in the process, as shown in Table 3. Listed in the table is that the reaction data of the catalyst that the ZSM-5 nuclei crystal of 25 is made is as comparative example in the table, and the result shows, compared with ZSM-5 nuclei crystal catalyst and all-silicon-shell phase catalyst (comparative example 1) , the core-shell molecular sieve catalyst has a high p-xylene selectivity, the deactivation speed of the catalyst is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com