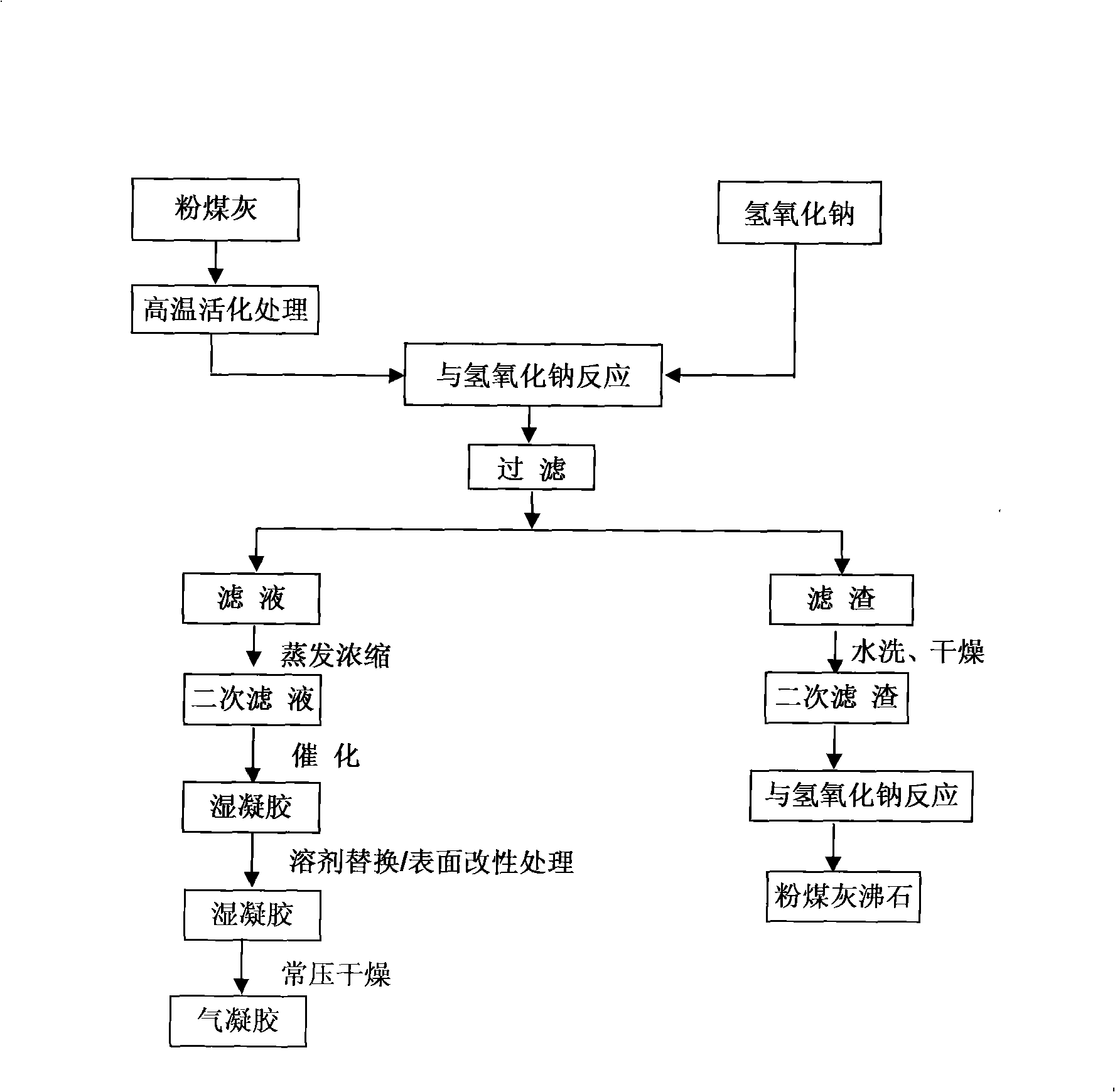

Method for simultaneously preparing SiO2 aerogel and zeolite by utilizing fly ash

A technology of fly ash and airgel, which is applied in the field of simultaneous preparation of SiO2 airgel and zeolite by using fly ash to achieve the effect of convenient and easy process, reducing working time and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] ① Preparation of water glass solution

[0055] The fly ash was treated at 600°C for 3 hours, boiled in a boiling water bath to remove impurities for 2 hours, and then reacted with sodium hydroxide aqueous solution for hydrothermal synthesis. 12wt%, the reaction temperature is 100°C, and the reaction time is 4h; 30ml of hot deionized water (60-80°C) is added to replenish the volatilized water when the reaction is 2h. The reaction mixture was filtered with a vacuum pump to obtain a primary filtrate, and the filter residue was washed with 300ml deionized water and filtered to obtain a secondary filtrate. After the two filtrates were mixed, they were evaporated and concentrated in a water bath at 70°C to 80°C to 100ml to obtain a water glass solution with a modulus of 0.71; at the same time, the filter residue was collected for the preparation of zeolite materials.

[0056] ② Preparation of SiO 2 Hydrogels

[0057] Take 40ml of the prepared water glass solution, adjust t...

Embodiment 2

[0066] ① Preparation of water glass solution

[0067] Fly ash was subjected to high temperature treatment at 700°C for 2 hours, and then carried out hydrothermal synthesis reaction with aqueous sodium hydroxide solution. Add 30ml of hot deionized water at 2h to replenish the evaporated moisture; the reaction mixture was filtered with a vacuum pump to obtain a primary filtrate, the filter residue was washed with 300mL of deionized water and suction filtered to obtain a secondary filtrate, and the two obtained After the filtrates are mixed, they are evaporated and concentrated to 80 ml in a water bath at 70° C. to 80° C. to obtain a water glass solution with a modulus of 0.79; meanwhile, filter residues are collected for preparing zeolite materials.

[0068] ② Preparation of SiO 2 Hydrogels

[0069] Take 20ml of the prepared water glass solution and mix it fully with 30ml of deionized water, and then perform ion exchange with styrene cation exchange resin activated by 4% hydro...

Embodiment 3

[0078] ① Preparation of water glass solution

[0079] The fly ash was treated at 600°C for 2 hours, boiled in a boiling water bath to remove impurities for 2 hours, and then hydrothermally synthesized with sodium hydroxide aqueous solution. The reaction alkali-slag ratio was 0.5, the concentration of NaOH solution was 18wt%, and the reaction temperature was 100°C , the reaction time is 4h, 30ml of hot deionized water is added to supplement the volatilized water when the reaction is 2h; the reaction mixture is filtered with a vacuum pump to obtain a filtrate, and the filter residue is washed with 300ml of deionized water and filtered to obtain a second The filtrate, after mixing the obtained filtrate twice, evaporated and concentrated to 100ml in a water bath at 70°C to 80°C to obtain a water glass solution with a modulus of 0.43.

[0080] ② Preparation of SiO 2 Hydrogels

[0081] Take 40ml of the prepared water glass solution, adjust the pH value to 10 with 2mol / l sulfuric a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com