Poly ferrosilicium coagulant and preparation method thereof

A technology of coagulant and polysilicon ferrosilicon, which is applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of complex preparation process, secondary pollution of the environment, and high production cost, and achieve low preparation cost, enhanced adaptability, and method simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

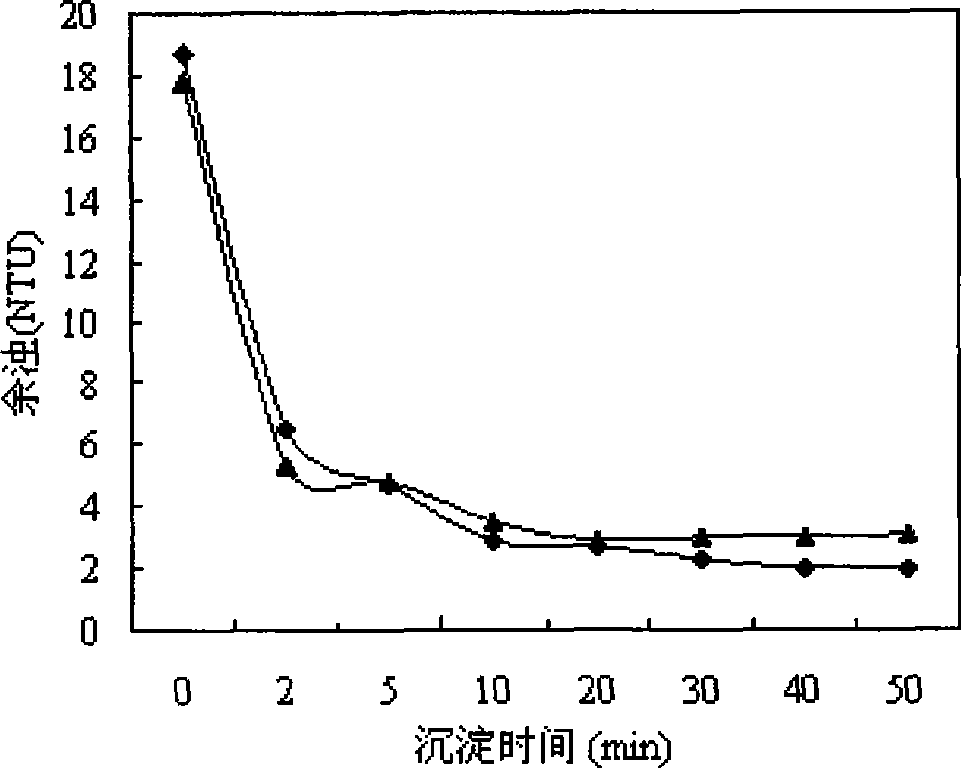

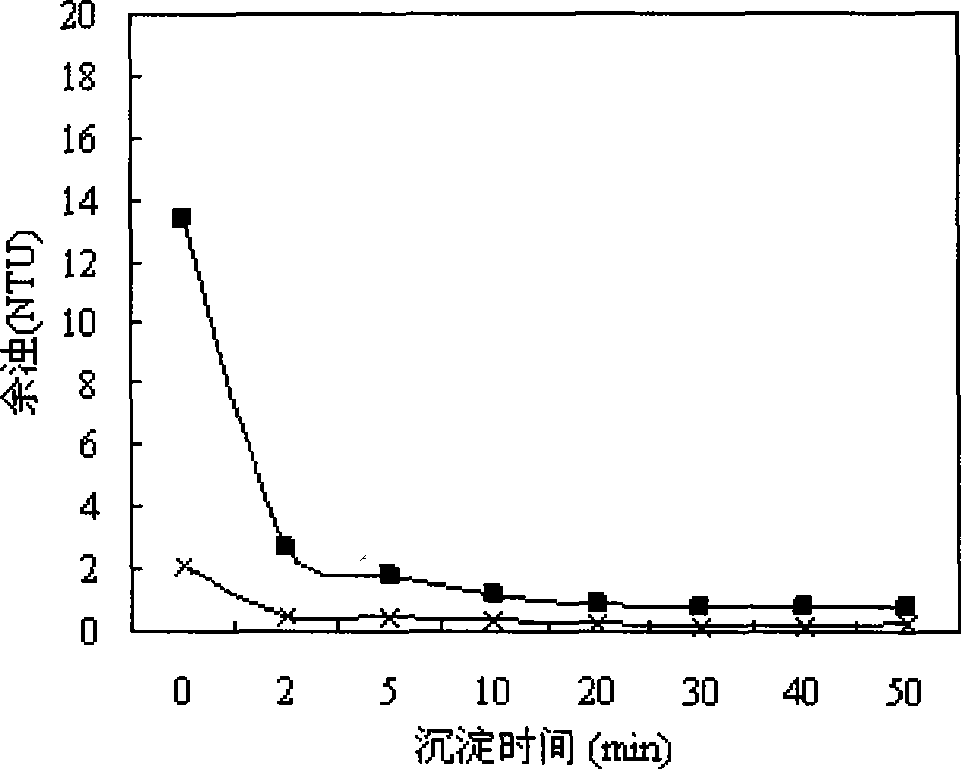

Image

Examples

specific Embodiment approach 1

[0012] Specific embodiment 1: The polysilicon ferrosilicon coagulant of this embodiment is composed of 20%-60% water glass, 10%-30% dilute acid solution, 10%-50% ferrous sulfate and 1.5% by weight. ~10% sodium chlorate; the solute of the dilute acid solution is sulfuric acid, hydrochloric acid, phosphoric acid or acetic acid, and the concentration of the dilute acid solution is 20%-50%.

specific Embodiment approach 2

[0013] Specific embodiment two: the difference between this embodiment and the specific embodiment one is: the polysilicon ferrosilicon coagulant is composed of 30%-50% water glass, 15%-25% dilute acid solution, 20%- It is made of 40% ferrous sulfate and 3% to 8.5% sodium chlorate; the concentration of the dilute acid solution is 30% to 40%. Others are the same as the first embodiment.

specific Embodiment approach 3

[0014] Specific embodiment three: the difference between this embodiment and specific embodiment one is: polysilicon ferrosilicon coagulant is composed of 40% water glass, 20% dilute acid solution, 30% ferrous sulfate and 10% by weight. Made of sodium chlorate; the concentration of the dilute acid solution is 35%. Others are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com